A layered perovskite catalyst for hydrogen production by autothermal reforming of acetic acid and preparation method thereof

An autothermal reforming and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as catalyst deactivation, and achieve high hydrogen yield , good thermal stability, enhanced anti-coking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

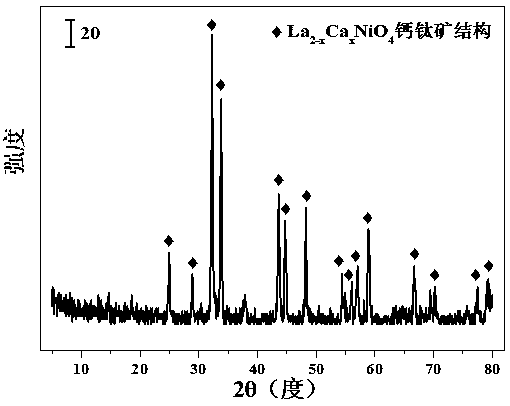

[0028] Weigh 8.6494 grams of La(NO 3 ) 3 ·6H 2 O and 2.9044 grams of Ni(NO 3 ) 2 ·6H 2 O, add 30ml of deionized water to make solution #1; then weigh 6.2966 grams of citric acid C 6 H 8 O 7 ·H 2 O, add 30ml of deionized water to make solution #2; then weigh 1.8599 grams of ethylene glycol (CH 2 OH) 2 ; Slowly add solution #1 and ethylene glycol to solution #2 dropwise, and stir at 70°C for 4 hours, the solution is gradually converted into colloid, and transferred to a drying oven at 105°C for 12 hours. Put the dried sample in a porcelain boat, put it in a tube furnace, heat it up to 700°C at a rate of 10°C / min, keep it at 700°C for 6 hours, and observe by scanning electron microscope and X-ray diffractometer. The catalyst CDUT-LN with a layered perovskite structure is obtained, and its molar composition is La 2 NiO 4 , Its typical XRD spectrum is attached figure 1 Shown. The weight composition of the catalyst is: the content of lanthanum oxide is 81.4%, and the content of nicke...

Embodiment 1

[0032] Weigh 5.8979 grams of La(NO 3 ) 3 ·6H 2 O,, 3.908 grams of Ni(NO 3 ) 2 ·6H 2 O and 3.2165 grams of Ca(NO 3 ) 2 ·4H 2 O, add 30ml of deionized water to make solution #1. Weigh 8.5863 grams of C 6 H 8 O 7 ·H 2 O, add 30ml of deionized water to make solution #2. Weigh out 2.5362 grams of (CH 2 OH) 2 . Solution #1 and ethylene glycol were slowly added dropwise to solution #2, and stirred at 70°C for 4 hours. The solution was gradually transformed into colloids and transferred to a drying oven at 105°C for 12 hours. Put the dried sample in a porcelain boat, put it in a tube furnace, raise the temperature to 700°C at a rate of 10°C / min, and keep it at 700°C for 6 hours to obtain a CDUT- with a layered perovskite structure. LC10N catalyst, its molar composition is LaCaNiO 4 , Its XRD spectrum is attached figure 1 As shown, the results show that after adding the additive Ca, a layered perovskite structure is still formed. The weight composition of the catalyst is: the content...

Embodiment 2

[0035] Weigh 3.6045 grams of La(NO 3 ) 3 ·6H 2 O,, 4.8414 grams of Ni(NO 3 ) 2 ·6H 2 O and 5.8973 grams of Ca(NO 3 ) 2 ·4H 2 O, add 30ml of deionized water to make solution #1. Weigh 10.465 grams of C 6 H 8 O 7 ·H 2 O, add 30ml of deionized water to make solution #2. Weigh 3.1004 grams of (CH 2 OH) 2 . Solution #1 and ethylene glycol were slowly added dropwise to solution #2, and stirred at 70°C for 4 hours. The solution was gradually transformed into colloids and transferred to a drying oven at 105°C for 12 hours. Put the dried sample in a porcelain boat, put it in a tube furnace, heat it up to 700°C at a rate of 70°C / min, and keep it at 700°C for 6 hours to obtain a CDUT- with a layered perovskite structure. LC15N catalyst, its molar composition is La 0.5 Ca 1.5 NiO 4 , Through the XRD test, the results showed that the catalyst formed a layered perovskite structure, accompanied by a small amount of calcium oxide phase formation. The weight composition of the catalyst is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com