CO2 stimuli-responsive solid emulsion

A stimuli-responsive, CO2 technology, applied in the field of emulsion polymerization, can solve problems such as difficult and impossible re-dispersion of emulsions, inactivation of chemical substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1. With CO 2 Stimulus response polystyrene emulsion and dry powder preparation

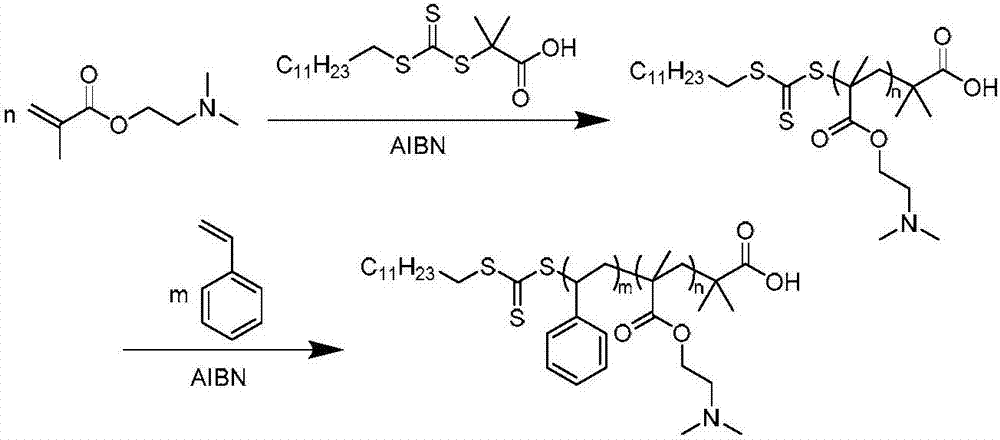

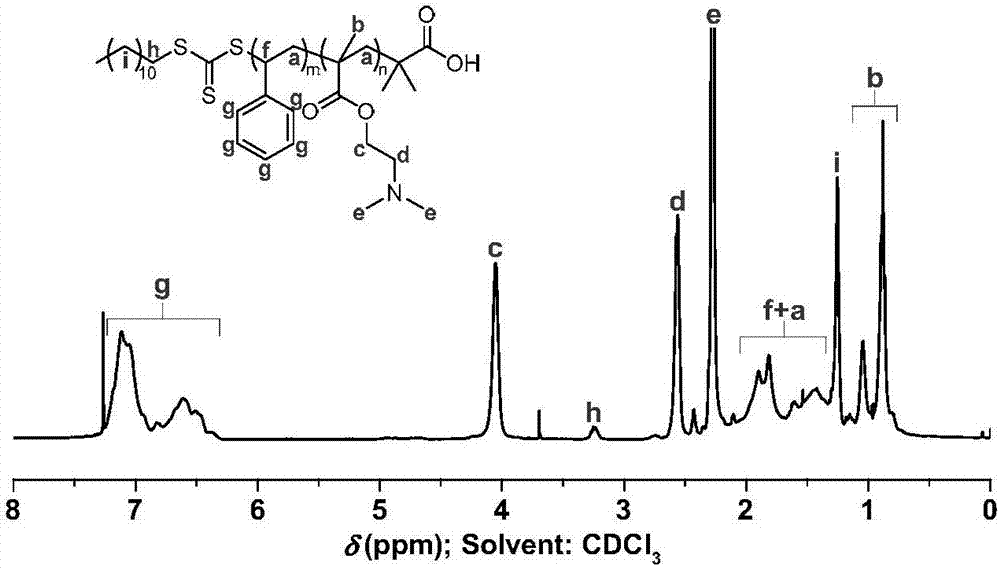

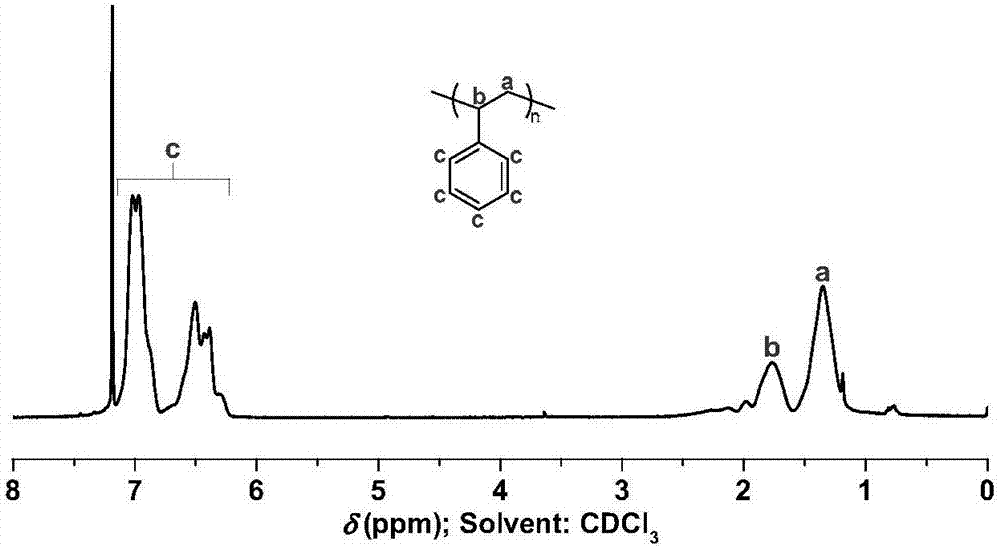

[0062] (1) Synthesis of diblock copolymer surfactant

[0063] The two-block copolymer surfactant polydimethylaminoethyl methacrylate-b-polystyrene is obtained by two-step RAFT polymerization, such as figure 1 Shown.

[0064] In the first step, the RAFT chain transfer agent (2-(dodecyltrithiocarbonate)-2-methylpropionic acid) (0.218g, 0.6mmol), dimethylaminoethyl methacrylate (abbreviated DMAEMA, 0.943g, 6mmol), initiator azobisisobutyronitrile (abbreviated as AIBN, 9.85mg, 0.06mmol) and 1,4-dioxane (1.5mL) were added to the Schlenk tube, and N 2 Remove oxygen for 30min, and then react for 8h at 70°C with stirring. After the reaction, the Schlenk tube was quenched in liquid nitrogen, diluted with 1,4-dioxane (2 mL), and precipitated twice in cold n-hexane. The purified product was vacuum dried overnight at room temperature to obtain a yellow solid, that is, the intermediate product RAFT ...

Embodiment 2

[0077] Example 2. With CO 2 Preparation of stimulus-responsive polymethylmethacrylate-polystyrene emulsion and dry powder

[0078] (1) Synthesis of diblock copolymer surfactant

[0079] The preparation method is the same as in Example 1 of the present invention.

[0080] (2) Emulsion polymerization

[0081] Put PDMAEMA10-b-PS10 (0.077g, 0.025mmol) through CO in an ice water bath 2 Dissolve in deionized water (15g) under the condition of 15min; at the same time, the initiator azobisimidazolinylpropane (21.4mg, 0.085 mmol) is passed CO in an ice water bath 2 Dissolve in another portion of deionized water (5g) under the condition of 15min, and then mix azobisimidazolinylpropane, St (1.111g, 10.67mmol) and methyl methacrylate (abbreviated as MMA, 1.111g, 11.1mmol) ) Add PDMAEMA10-b-PS10 aqueous solution successively, and then pass CO in an ice water bath 2 15min, then react for 6h at 55°C with stirring.

[0082] The number average molecular weight of the polymer latex particles in the o...

Embodiment 3

[0088] Example 3. With CO 2 Preparation of stimulus-responsive polyethylmethacrylate-polystyrene emulsion and dry powder

[0089] (1) Synthesis of diblock copolymer surfactant

[0090] The preparation method is the same as in Example 1 of the present invention.

[0091] (2) Emulsion polymerization

[0092] Put PDMAEMA10-b-PS10 (0.077g, 0.025mmol) through CO in an ice water bath 2 Dissolve in deionized water (15g) under the condition of 15min; at the same time, the initiator azobisimidazolinylpropane (21.4mg, 0.085 mmol) is passed CO in an ice water bath 2 Dissolve in another portion of deionized water (5g) under the condition of 15min, then mix azobisimidazolinylpropane, St (1.111g, 10.67mmol) and ethyl methacrylate (referred to as EMA, 1.111g, 9.73mmol) ) Add PDMAEMA10-b-PS10 aqueous solution successively, and then pass CO in an ice water bath 2 15min, then react for 6h at 55°C with stirring.

[0093] The number average molecular weight of the polymer latex particles in the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com