Compound feed for micropterus salmoides fries

A technology of compound feed and fish fry, which is applied in the field of compound feed for California perch fry, can solve problems such as water quality deterioration, hidden dangers, and unpleasant smell, and achieve the effects of meeting growth needs, ensuring rapid growth, and improving intestinal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

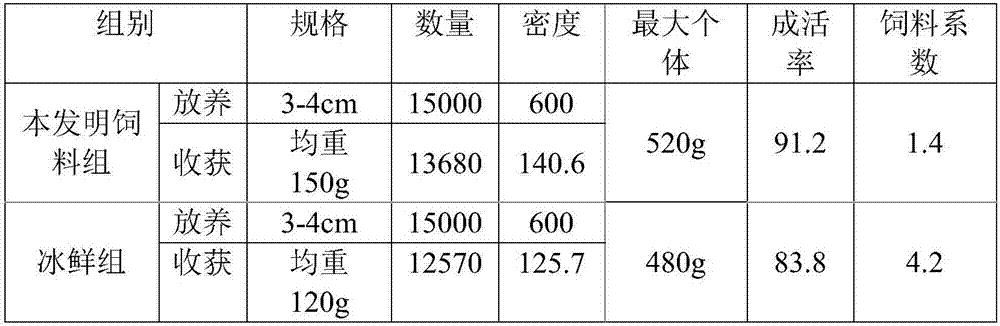

Examples

Embodiment 1

[0026] A California perch fry compound feed is prepared by mixing the following raw materials in parts by weight: 20 parts of imported white fish meal, 15 parts of enzyme collagen short fiber, 15 parts of snail powder, 10 parts of earthworm powder, 6 parts of kelp powder, spray 15 parts of soybean dregs, 6 parts of grape seed meal, 10 parts of starch, 3 parts of starch dregs, 5 parts of fish oil, 5 parts of soybean lecithin powder, 3 parts of calcium dihydrogen phosphate, and 2 parts of choline chloride.

[0027] The enzyme collagen short fiber is made through the following steps:

[0028] (1) Mix 10 parts by weight of collagen, 4 parts by weight of fruit and vegetable enzyme powder, 1 part by weight of polylactic acid and 100 parts by weight of solvent hexafluoroisopropanol to obtain a spinning solution. The fruit and vegetable enzyme powder is prepared by the following method: after the fruit and vegetable raw materials are cleaned, sterilized and crushed, they are poured in...

Embodiment 2

[0032] A compound feed for California perch fry is prepared by mixing the following raw materials in parts by weight: 30 parts of imported white fish meal, 7 parts of enzyme collagen short fiber, 10 parts of snail powder, 5 parts of earthworm powder, 3 parts of kelp powder, spray 10 parts of soybean dregs, 3 parts of grape seed meal, 5 parts of starch, 16 parts of starch dregs, 3 parts of fish oil, 3 parts of soybean lecithin powder, 2 parts of calcium dihydrogen phosphate, and 1 part of choline chloride.

[0033] The enzyme collagen short fiber is made through the following steps:

[0034] (1) Mix 15 parts by weight of collagen, 5 parts by weight of fruit and vegetable enzyme powder, 2 parts by weight of polylactic acid and 100 parts by weight of solvent hexafluoroisopropanol to obtain a spinning solution. The fruit and vegetable enzyme powder is prepared by the following method: after the fruit and vegetable raw materials are cleaned, sterilized and broken, they are poured i...

Embodiment 3

[0038] A compound feed for California perch fry is prepared by mixing the following raw materials in parts by weight: 25 parts of imported white fish meal, 10 parts of enzyme collagen short fiber, 12 parts of snail powder, 8 parts of earthworm powder, 4 parts of kelp powder, spray 12 parts of soybean dregs, 4 parts of grape seed meal, 7 parts of starch, 10 parts of starch dregs, 4 parts of fish oil, 4 parts of soybean lecithin powder, 2.5 parts of calcium dihydrogen phosphate, and 1.5 parts of choline chloride.

[0039] The enzyme collagen short fiber is made through the following steps:

[0040] (1) Mix 12 parts by weight of collagen, 4.5 parts by weight of fruit and vegetable enzyme powder, 1.5 parts by weight of polylactic acid and 100 parts by weight of solvent hexafluoroisopropanol to obtain a spinning solution. The fruit and vegetable enzyme powder is prepared by the following method: after the fruit and vegetable raw materials are cleaned, sterilized and crushed, they a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com