Teflon superfine fiber supported titanium dioxide photocatalytic membrane and preparation method thereof

A technology of ultrafine fiber and titanium dioxide, applied in the field of photocatalysis, can solve the problems of incomplete removal, secondary pollution, long treatment cycle, etc., and achieve the effects of excellent temperature resistance, stable structure, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

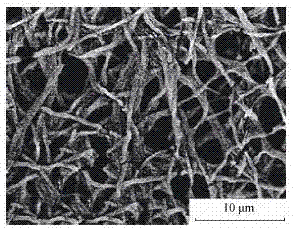

[0019] Prepare 10% PVA (polymerization degree 1700, alcoholysis degree 88%) aqueous solution; prepare a solution with 60% PTFE emulsion and PVA aqueous solution at a mass ratio of 15:1, and the total solubility of the spinning solution is 45%. Set the spinning parameters: the voltage is 30 kV, the receiving distance is 15 cm, the extrusion rate is 2 mL / h, and the rotating speed of the receiving disc is 200 r / min. Finally, PTFE ultrafine fibers are obtained. Prepare an impregnation solution with tetrabutyl titanate, anhydrous acetic acid, and absolute ethanol at a ratio of 1:2:4, immerse PTFE microfibers in the impregnation solution for 5 hours, dry at 100°C, and place in a muffle furnace Calcined at 450℃ for 10min to prepare TiO 2 / PTFE microfiber catalytic membrane.

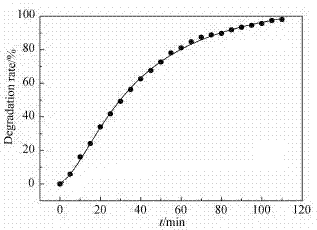

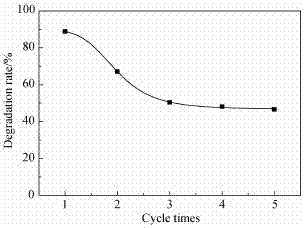

[0020] With methylene blue as the degradation target, 100 mL of methylene blue solution with an initial concentration of 5 mg / L was placed in a 250 mL beaker, and 0.5 g of photocatalyst was added. Under the ir...

Embodiment 2

[0026] Prepare a 10% PVA (polymerization degree 1800, alcoholysis degree 88%) aqueous solution; prepare a solution with 60% PTFE emulsion and PVA aqueous solution at a mass ratio of 15:1, and the total solubility of the spinning solution is 40%. Set the spinning parameters: the voltage is 30 kV, the receiving distance is 15 cm, the extrusion rate is 2 mL / h, and the rotating speed of the receiving disc is 200 r / min. Finally, PTFE ultrafine fibers are obtained. Tetrabutyl titanate, anhydrous acetic acid, anhydrous ethanol according to the ratio

[0027] Prepare an impregnating solution with a quality of 1:2:4, place PTFE ultrafine fibers in the impregnating solution for 5 hours, dry at 100°C, and calcinate in a muffle furnace at 450°C for 15 minutes to obtain TiO 2 / PTFE microfiber catalytic membrane.

[0028] With methylene blue as the degradation target, 100 mL of methylene blue solution with an initial concentration of 5 mg / L was placed in a 250 mL beaker, and 0.5 g of photo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com