A kind of preparation method of graphene oxide/titanium dioxide nanotube composite material

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc., can solve problems such as difficult recycling, easy agglomeration of material components, poor dispersion, etc., to achieve convenient operation, High mechanical strength and strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

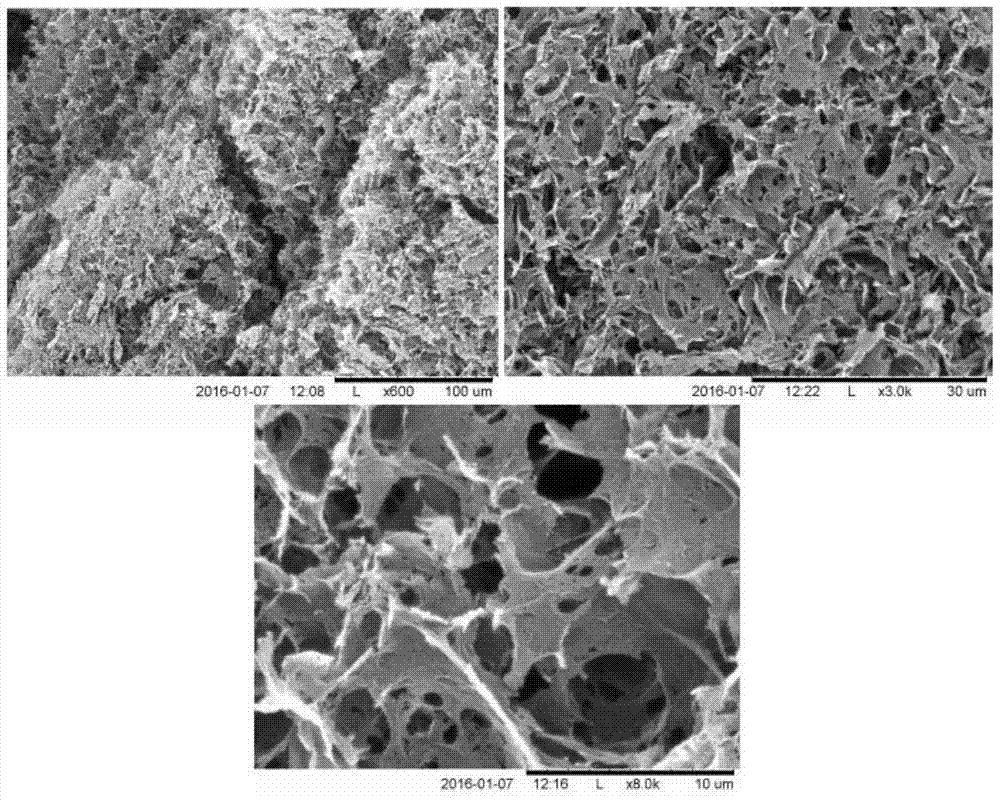

[0036] A preparation method of graphene oxide / titanium dioxide nanotube composite material, comprising the following steps:

[0037] Step 1. Take 0.5g of titanium dioxide powder and add it to 50mL of 10M sodium hydroxide solution. Ultrasound for 1h and then stir for 1h to make it fully mixed. Transfer the suspension to a polytetrafluoroethylene reactor and react at 130°C for 24h. After cooling to room temperature, the reaction product was washed three times with water-acid wash-washed to neutrality, then dried and ground to obtain titanium dioxide nanotubes;

[0038] Get titanium dioxide nanotube 5g and 1-ethyl-3-methyl imidazole chloride 0.5g, add 100g distilled water, stir 7 days with 300r / min, obtain titanium dioxide nanotube dispersion liquid, then titanium dioxide nanotube dispersion liquid is in 4000r Centrifuge at a speed of 10 min for 10 min, and take the upper turbid liquid for later use;

[0039] Step 2. Add chitosan to 2wt% glacial acetic acid at room temperature, ...

Embodiment 2

[0043] A preparation method of graphene oxide / titanium dioxide nanotube composite material, comprising the following steps:

[0044] Step 1. Take 0.7g of titanium dioxide powder and add it to 70mL of 10M sodium hydroxide solution. Ultrasound for 1h and then stir for 1h to make it fully mixed. Transfer the suspension to a polytetrafluoroethylene reactor and react at 130°C for 24h. After cooling to room temperature, the reaction product was washed three times with water-acid wash-washed to neutrality, then dried and ground to obtain titanium dioxide nanotubes;

[0045] Get titanium dioxide nanotube 1g and 1-ethyl-3-methylimidazole chloride 0.3g, add 100g distilled water, stir 7 days with 300r / min, obtain titanium dioxide nanotube dispersion liquid, then titanium dioxide nanotube dispersion liquid is in 3000r Centrifuge at a speed of 10 min for 10 min, and take the upper turbid liquid for later use;

[0046] Step 2. Add chitosan to 2wt% glacial acetic acid at room temperature, s...

Embodiment 3

[0050] A preparation method of graphene oxide / titanium dioxide nanotube composite material, comprising the following steps:

[0051] Step 1. Take 1g of titanium dioxide powder and add it to 80mL of 10M sodium hydroxide solution. Ultrasound for 1h and then stir for 1h to make it fully mixed. Transfer the suspension to a polytetrafluoroethylene reactor and react at 130°C for 24h. The reaction is complete. After cooling to room temperature, the reaction product was washed three times with water-acid wash-washed to neutrality, then dried and ground to obtain titanium dioxide nanotubes;

[0052] Get titanium dioxide nanotube 3g and 1-ethyl-3-methyl imidazole chloride 0.5g, add 100g distilled water, stir 7 days with 300r / min, obtain titanium dioxide nanotube dispersion liquid, then titanium dioxide nanotube dispersion liquid is in 4000r Centrifuge at a speed of 10 min for 10 min, and take the upper turbid liquid for later use;

[0053] Step 2. Add chitosan to 2wt% glacial acetic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com