Biological dispersing agent for circulating cooling water and preparation method thereof

A circulating cooling water and dispersant technology, which is applied to chemical instruments and methods, natural water treatment, non-polluted water treatment, etc., can solve the problems affecting the normal operation of circulating cooling water, failure, and the loss of the effect of the two agents, and achieve good results. Broad-spectrum bactericidal effect, enhanced dispersing ability, and good wetting and penetrating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example relates to a biodispersant for circulating cooling water and its preparation.

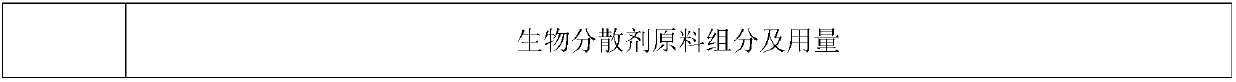

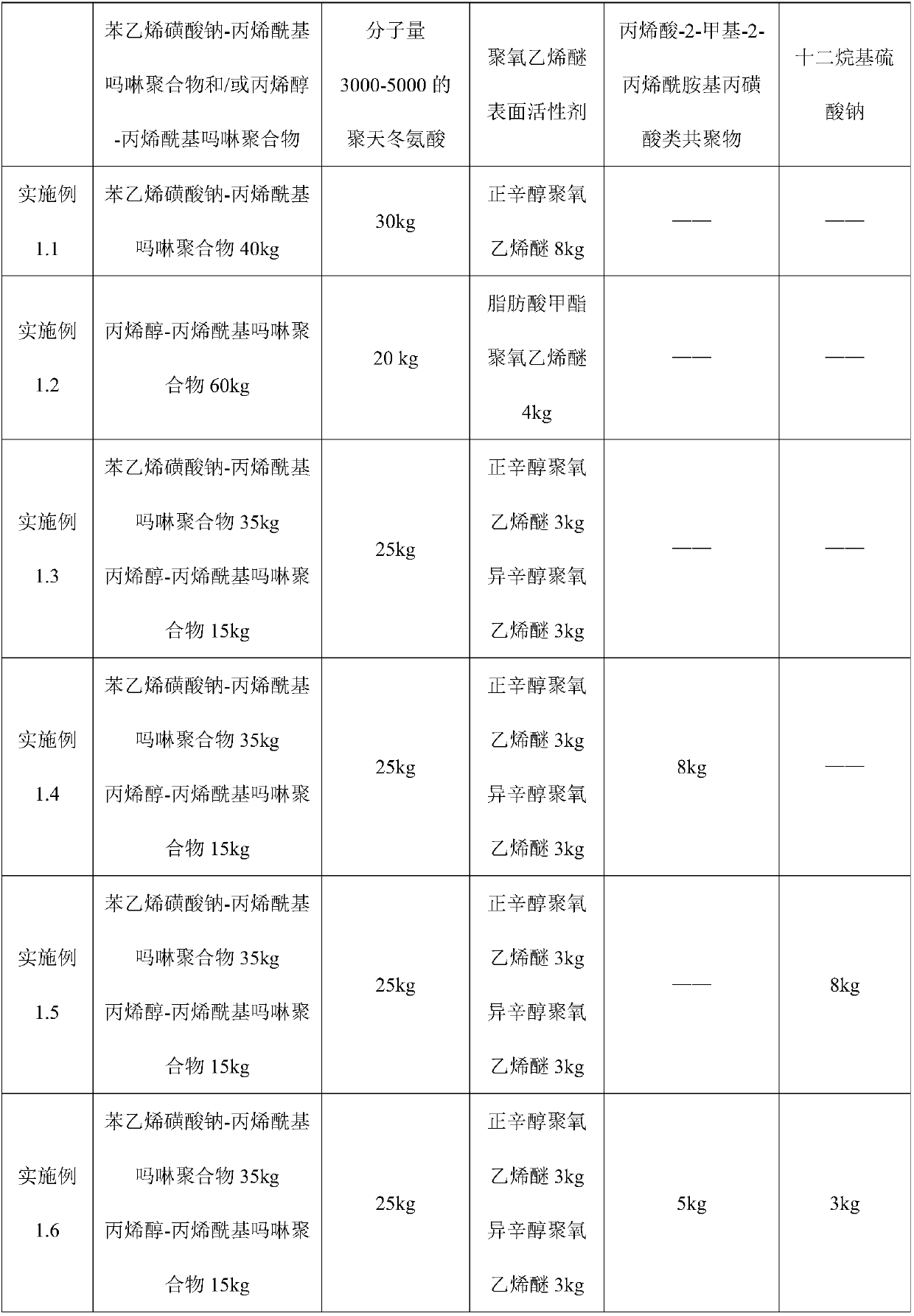

[0032] A group of biodispersant for circulating cooling water, its raw material formula is shown in the following table:

[0033]

[0034]

[0035] Prepare as follows:

[0036]a. Take polyaspartic acid with a molecular weight of 3000-5000, add it to the reaction vessel, add polyoxyethylene ether surfactant under stirring, stir at room temperature 25°C for 30-60min, make it mix evenly, and get Solution A;

[0037] b. Put sodium styrene sulfonate-acryloyl morpholine polymer and / or acryl alcohol-acryloyl morpholine polymer into another reaction vessel, add deionized water, the amount of water added can be adjusted according to the actual situation, and it needs to be ensured The viscosity of the solution during the stirring process is suitable, and the solid content of the prepared biodispersant is ≥ 40%; stir at room temperature 25°C for 30-60min, and adjust the pH to abou...

Embodiment 2

[0051] This example relates to Example 1, that is, the comparison of the treatment effects of the biodispersant of the present invention and the biodispersant of the comparative example on circulating cooling water.

[0052] The main indicators of the water quality of the circulating cooling water system of a coking plant are as follows:

[0053] water quality index hydrating Recycled water Calcium hardness (as CaCO3), mg / L 216.20 463.09 Total hardness (as CaCO3), mg / L 324.29 730.74 Total Alkalinity (as CaCO3), mg / L 163.01 364.16 Chloride ion mg / L 39.70 97.27 PH value 7.82 8.84 Turbidity NTU 3.2 15.0 COD 14.7 38.0

[0054] The biodispersant of Example 1 and the biodispersant of Comparative Example were used together with fungicides and scale and corrosion inhibitors to carry out water quality treatment simulation experiments.

[0055] In the following simulation experiments, the laboratory evaluation method of b...

Embodiment 3

[0067] This example relates to the evaluation of the application effect of the biodispersant of the present invention in an industrial circulating cooling water system.

[0068] The biodispersant of Example 1.6 was tested on-site, and compared with the field application effect of Comparative Example 1.3, which is a commonly used biodispersant in this field.

[0069] The performance of the agent was evaluated by the extracellular polymer method and the method of measuring the amount of biological slime. The determination of polysaccharide and nucleic acid content is the same as the experimental operation steps in Example 2. The determination of the amount of biological slime is carried out in accordance with the national standard GB / T 14643.1-2009 for the analysis method of industrial circulating cooling water.

[0070] Field application test conditions: the circulation volume of the circulating water system is 6500m 3 / h, system volume 3000m 3 , the concentration factor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com