Method for producing olea europaea wine by utilizing olea europaea fruits and leaves

A technology of olive fruit and olive leaf, applied in the field of fruit wine brewing, can solve problems such as waste of olive leaf, ineffective release of effective components of olive fruit and leaf, and achieve the effects of improving quality, retaining aroma components and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Utilize olive fruit and leaf to produce olive wine

[0028] 1. Low-temperature cold pressing: Fresh olives are cold-pressed at ≤30°C within 24 hours, then the juice is pumped into the fermentation tank, and 0.5% of rouge rice is added to the fermentation tank as a carbon source for fermentation to enrich the potassium in the wine body , iron, magnesium and other trace elements.

[0029] 2. Saccharified fruit juice: heat the fruit juice in step (1) to 88-93°C, add liquefaction enzyme, liquefy at 88-93°C for 4 hours, then cool down to 60°C and add saccharification enzyme for saccharification for 2 hours. The weight ratio of fruit juice and saccharification enzyme is 1:0.15.

[0030] 3. Enzymolysis: add olive leaves crushed to 100 meshes to the saccharification solution in step (2), cool down to 45°C and add pectinase for enzymolysis for 1 hour. The enzymolysis temperature is 45°C-50°C. The addition amount is 0.03-0.05% of the weight of the saccharified liq...

Embodiment 2

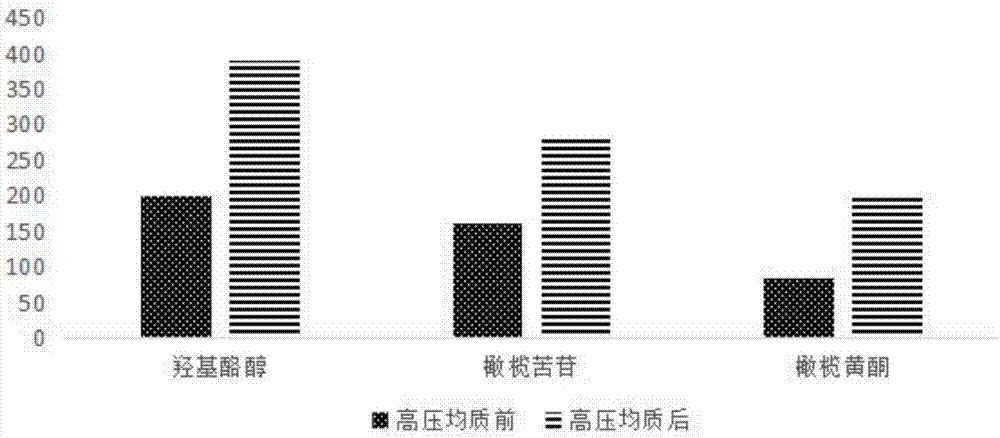

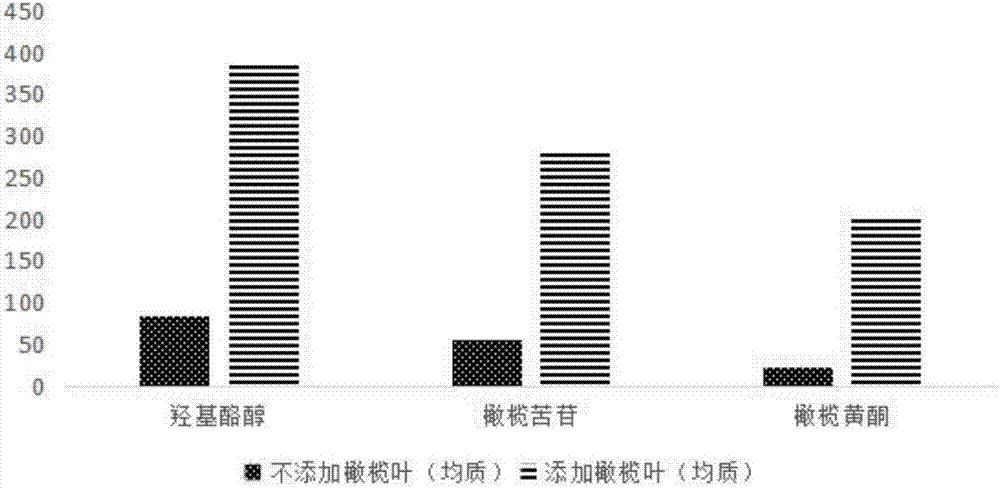

[0036] Embodiment 2: Determination of hydroxytyrosol, oleuropein, and olive flavonoids in olive wine

[0037] 1. Preparation of the solution to be tested:

[0038] ① Take 1 mL of the fruit wine in Example 1, put it in a 15 mL centrifuge tube, add 9 mL of 70% methanol solution, mix at room temperature for 1 min, and filter for later use.

[0039] The solution to be tested obtained from the fruit wine that has not been homogenized under high pressure by the above-mentioned pretreatment method is used as the reference substance.

[0040] ② Take 1 mL of the fruit wine in Example 1, put it in a 15 mL centrifuge tube, add 9 mL of 70% methanol solution, mix at room temperature for 1 min, and filter for later use.

[0041] Take the high-pressure homogenized fruit wine without adding olive leaves and obtain the test solution obtained by the above-mentioned pretreatment method as the reference substance.

[0042] 2. Preparation of reference solution:

[0043] Prepare standard solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com