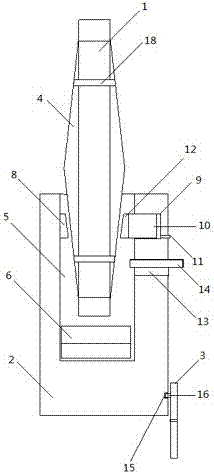

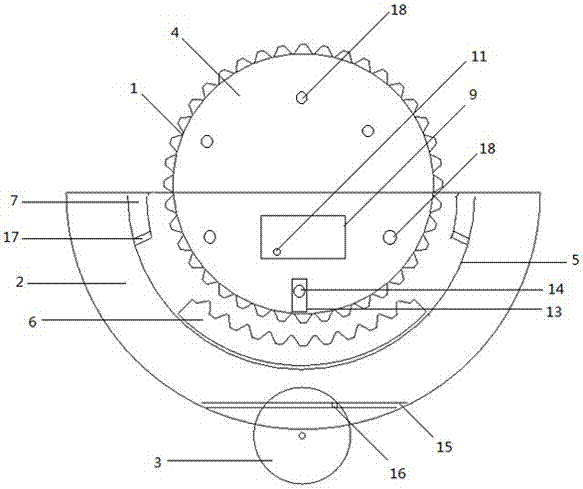

Disc brake adopting novel brake material for load-carrying vehicle

A technology of disc brakes and brake materials, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of difficulty in dissipating braking energy, reduced braking efficiency, poor thermal conductivity, etc., to expand high-temperature braking. Condition range, braking safety, good friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A new type of brake material, the raw materials include: phenolic resin 10 parts, nitrile rubber 3 parts, graphene oxide 0.2 parts, lecithin 0.1 parts, liquid paraffin 0.1 parts, glutaraldehyde 2 parts, cardanol modified Polyamide resin 0.5 part, sodium bicarbonate 0.2 part, silicon carbide 0.4 part, ceramic fiber 4 part, lignin fiber 3 part, microcrystalline cellulose 0.1 part, ethylene / vinyl acetate copolymer 0.2 part, magnesium oxide 2 part , 1 part of quartz sand, 2 parts of calcium sulfide, 0.5 part of ethyl methacrylate.

[0038] Among them, the particle size of microcrystalline cellulose is 60 mesh, and the diameter of ceramic fiber is 2.0 μm.

[0039] The preparation method of the truck rear disc brake material includes the following steps:

[0040] Step 1. Mix the phenolic resin with nitrile rubber, graphene oxide, lecithin, liquid paraffin, and glutaraldehyde. The mixture is heated to 100°C under the protection of nitrogen, kept for 40 minutes, and cooled to room te...

Embodiment 2

[0045] A new type of brake material, the raw materials include: phenolic resin 10 parts, nitrile rubber 4 parts, graphene oxide 0.5 parts, lecithin 0.4 parts, liquid paraffin 0.3 parts, glutaraldehyde 4 parts, cardanol modified Polyamide resin 0.9 parts, sodium bicarbonate 0.3 parts, silicon carbide 0.7 parts, ceramic fiber 7 parts, lignin fiber 6 parts, microcrystalline cellulose 0.2 parts, ethylene / vinyl acetate copolymer 0.5 parts, magnesium oxide 4 parts , 2 parts of quartz sand, 3 parts of barium sulfide, 0.7 parts of ethyl methacrylate.

[0046] Among them, the particle size of microcrystalline cellulose is 80 mesh, and the diameter of ceramic fiber is 3.0 μm.

[0047] The preparation method of the truck rear disc brake material includes the following steps:

[0048] Step 1. Mix the phenolic resin with nitrile rubber, graphene oxide, lecithin, liquid paraffin, and glutaraldehyde. The mixture is heated to 120°C under the protection of nitrogen, kept for 35 minutes, and cooled t...

Embodiment 3

[0053] A new type of brake material, the raw materials include: phenolic resin 10 parts, nitrile rubber 6 parts, graphene oxide 0.5 parts, lecithin 0.2 parts, liquid paraffin 0.4 parts, glutaraldehyde 5 parts, cardanol modified 1.1 parts of polyamide resin, 0.3 parts of sodium bicarbonate, 0.7 parts of silicon carbide, 7 parts of ceramic fiber, 8 parts of lignin fiber, 0.3 part of microcrystalline cellulose, 0.5 part of ethylene / vinyl acetate copolymer, 4 parts of magnesium oxide , 2 parts of quartz sand, 4 parts of strontium sulfide, 0.6 parts of ethyl methacrylate.

[0054] Among them, the particle size of microcrystalline cellulose is 60 mesh, and the diameter of ceramic fiber is 2.0 μm.

[0055] The preparation method of the truck rear disc brake material includes the following steps:

[0056] Step 1. Mix the phenolic resin with nitrile rubber, graphene oxide, lecithin, liquid paraffin, and glutaraldehyde. The mixture is heated to 100°C under the protection of nitrogen, kept for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com