Polymer solid-state electrolyte material and preparation method therefor

A technology of solid electrolytes and polymers, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve problems such as limiting the performance of electrolytes, failing to meet industrial production, and failing to significantly improve the mechanical properties of electrolytes, so as to achieve strong controllability in the production process , Improvement of mechanical properties, good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

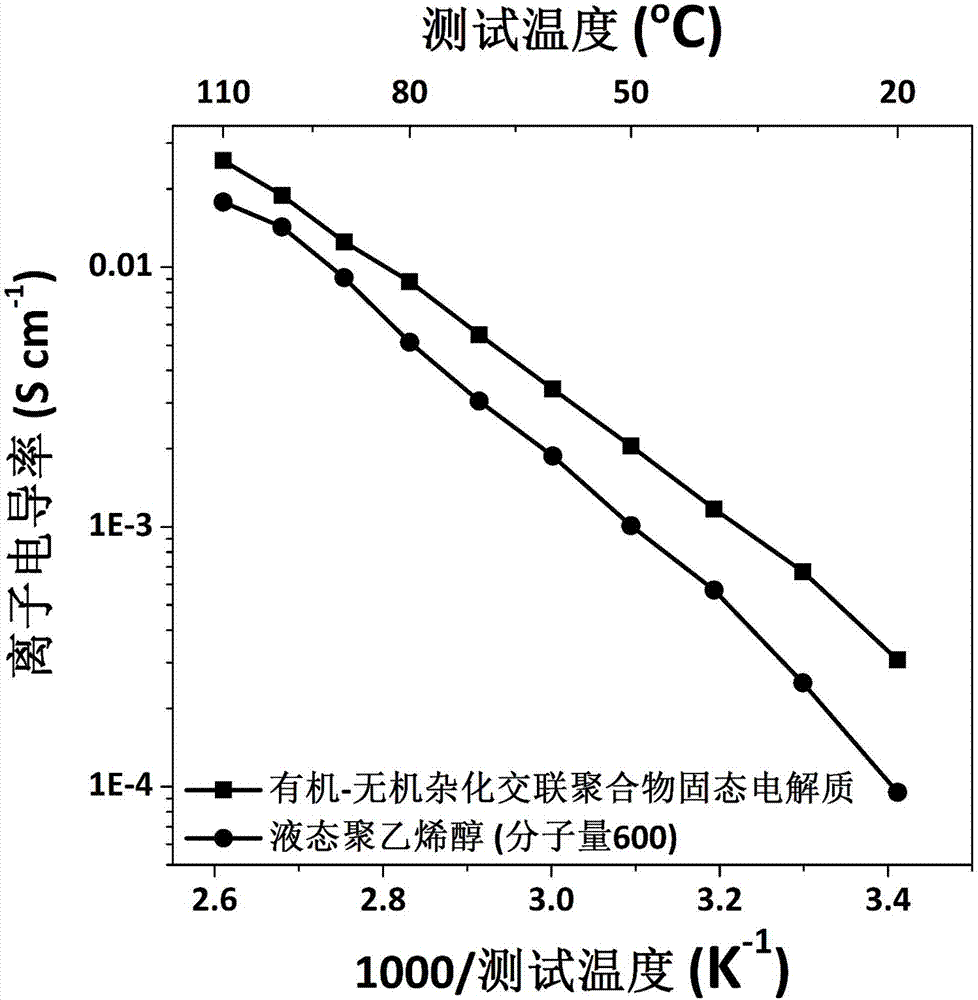

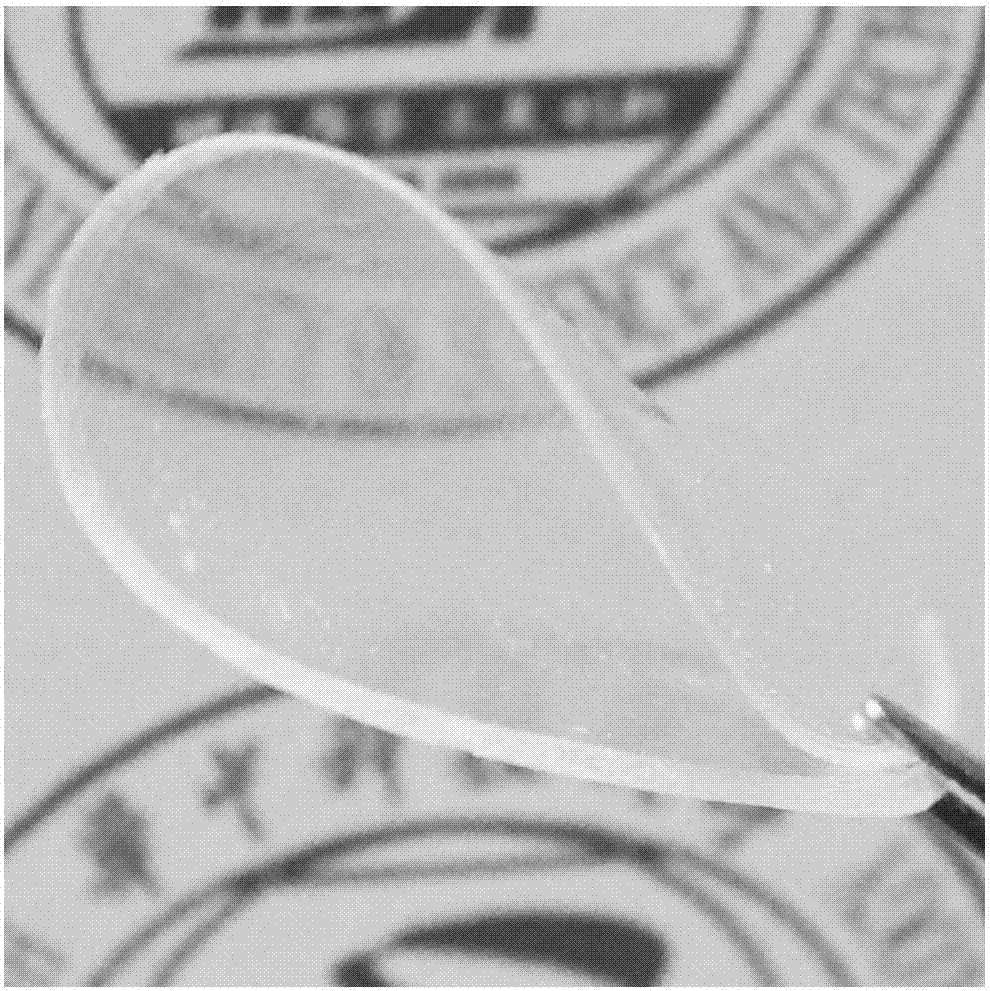

[0030] In the present invention, the preparation method of the inorganic-organic hybrid cross-linked polymer solid electrolyte is to use a certain ratio of silicon dioxide nanoparticles with surface-modified mercapto groups, double bond-terminated polyethylene glycol, photoinitiator and lithium salt The slurry required for the polymerization reaction is pre-prepared, and without adding any external solvent, the system polymerization is initiated by ultraviolet light irradiation to obtain the target solid electrolyte; the lithium-ion battery uses organic-inorganic hybrid cross-linking polymerization A preparation method for a solid state electrolyte material, comprising the following steps:

[0031] (1) Place the silicon dioxide nanoparticles in an aqueous sodium hydroxide solution for activation treatment at 60°C to 90°C for 2 to 24 hours, the ratio of the silicon dioxide nanoparticles to the aqueous sodium hydroxide solution is 1g / 100mL to 1g / 2mL, and then Cool to room temper...

Embodiment 1

[0038] Organic-inorganic hybrid crosslinked network solid electrolyte material, specifically, silica nanoparticles modified with mercaptopropyltrimethoxysilane and polyethylene glycol dimethacrylate with a molecular weight of 200 are crosslinked by ultraviolet light irradiation technology Obtained, the mass ratio of the two is 1 / 2; the doped lithium salt is lithium trifluoromethanesulfonate imide, and the molar ratio of ether oxygen group and lithium element in the system is 10 / 1; the used The photoinitiator is 1-hydroxycyclohexyl phenone, and the photoinitiator accounts for 0.1wt.% of the total mass of reactants.

[0039] The specific preparation method is:

[0040] Disperse 1g of silica particles with an average particle size of 20nm in 100mL of 0.1mol / L sodium hydroxide aqueous solution, oscillate ultrasonically for 30min, then heat and reflux at 80°C for 16h, filter with suction, wash with deionized water several times, and dry to obtain Surface activation of silica nanop...

Embodiment 2

[0042] An organic-inorganic hybrid crosslinked network solid electrolyte material, specifically, silica nanoparticles modified with mercaptopropyltrimethoxysilane and polyethylene glycol dimethacrylate with a molecular weight of 400 are crosslinked by ultraviolet light irradiation technology Obtained, the mass ratio of the two is 1 / 4; the doped lithium salt is lithium trifluoromethanesulfonate imide, and the molar ratio of ether oxygen group and lithium element in the system is 20 / 1; the used The photoinitiator is 2-hydroxyl-2-methylpropiophenone, and the photoinitiator accounts for 0.5wt.% of the total mass of reactants.

[0043] The specific preparation method is:

[0044]Disperse 2g of silica particles with an average particle size of 40nm in 100mL of 1mol / L sodium hydroxide aqueous solution, oscillate ultrasonically for 30min, then heat and reflux at 90°C for 8h, filter, wash with deionized water several times, and dry to obtain the surface Activates silica nanoparticles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com