Treating method and process flow for wastewater from oilfield

A treatment method and process technology, which is applied in the field of oily sewage treatment process, can solve the problems of low oil-water separation efficiency, large floor area, easy clogging, etc., and achieve the effect of realizing resource utilization and solving corrosion and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

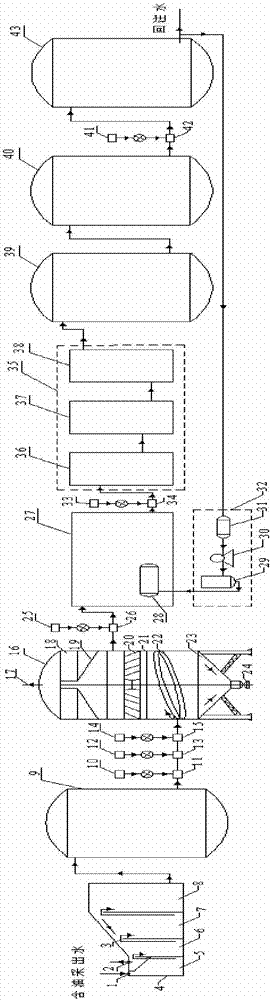

Image

Examples

Embodiment 1

[0034] Example 1: Treatment of oilfield produced water with high oil content, high sulfur content, and high bacterial content

[0035] 1. The produced water from the oil field is pretreated by multi-stage sedimentation in box-type settling tanks to remove part of the suspended solids, dispersed oil and slick oil;

[0036] 2. Then, the oil, water and solids are preliminarily separated through the sedimentation homogeneous adjustment tank, and 50-80 mg / L iron remover sodium hypochlorite and 50-150 mg / L sulfur remover zinc chloride are added to the oil production sewage, respectively. Remove iron and sulfide from iron and sulfide; then add 1.0 mg / L polyacrylamide organic polymer coagulant of 12 million units to flocculate the petroleum and suspended solids in the sewage;

[0037] 3. The treated oil production sewage enters the three-phase cyclone separation tank for oil, water and solid three-phase separation treatment again;

[0038] 4. After the three-phase separation, the oil...

Embodiment 2

[0044] Example 2: Treatment of oilfield produced water with high iron content, high oil content, and high bacterial content

[0045] 1. The produced water from the oil field is pretreated by multi-stage sedimentation in box-type settling tanks to remove part of the suspended solids, dispersed oil and slick oil;

[0046] 2. Then, the oil, water and solids are preliminarily separated through the sedimentation homogeneous adjustment tank, and 50-150 mg / L iron remover sodium hypochlorite and 40-80 mg / L sulfur remover zinc sulfate are added to the produced water, respectively. Remove iron and sulfur from iron and sulfide; then add 1.5 mg / L polyacrylamide organic polymer coagulant of 10 million units to flocculate the petroleum and suspended solids in the sewage;

[0047] 3. The treated oil production sewage enters the three-phase cyclone separation tank for oil, water and solid three-phase separation treatment again;

[0048] 4. After the three-phase separation, the oil production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com