Method using organic matter high-temperature carbonization to prepare carbon-based wave-absorbing material

A high-temperature carbonization and wave-absorbing material technology, applied in the field of wave-absorbing materials, can solve problems such as poor wave-absorbing effect, complicated preparation process, and high cost, and achieve the effects of low price, good repeatability, and strong absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

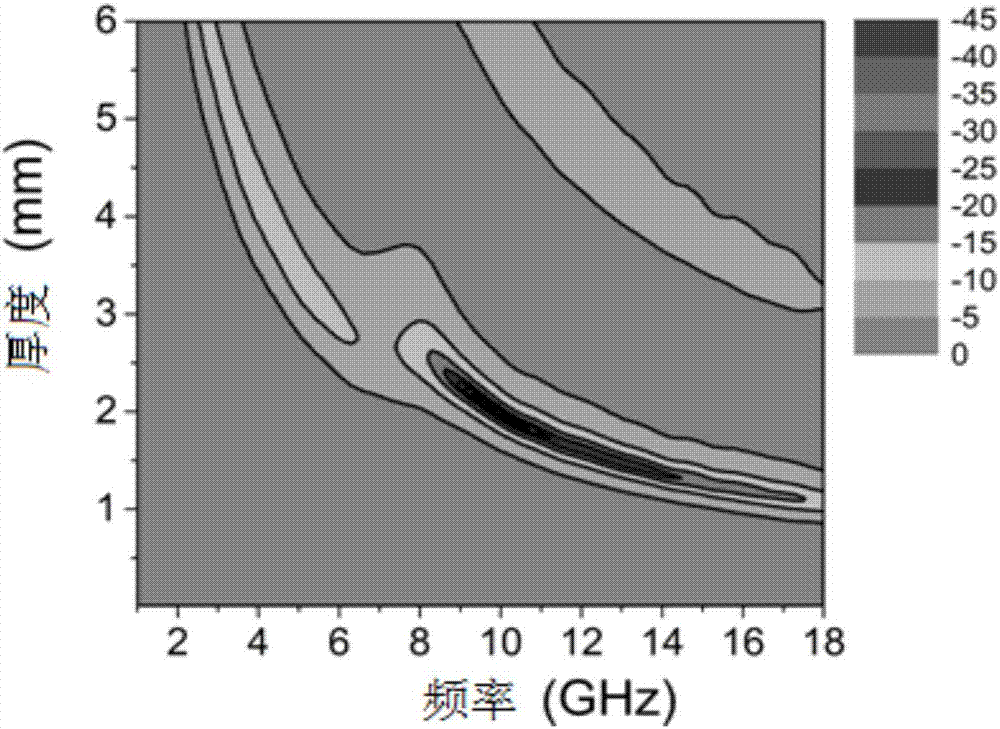

[0027] Example 1: Using the product of the hydrothermal reaction of sugar as a precursor, the specific steps for obtaining a carbon-based wave-absorbing material after high-temperature carbonization in a protective atmosphere are as follows:

[0028] (1) Hydrothermal carbonization of sugar: Prepare a solution of sucrose and deionized water at a molar ratio of 1:100, stir evenly and pour it into a polytetrafluoroethylene lining, put the lining into a stainless steel reaction kettle, place Reaction in a muffle furnace, the reaction temperature is 180°C, and the reaction time is 12 hours, so that the sugar can be fully converted into precursors through organic reactions such as dehydration and polycondensation;

[0029] (2) High-temperature carbonization of precursors: Take an appropriate amount of precursors in a corundum crucible, cover the crucible, and put it into a furnace for high-temperature carbonization treatment. The carbonization temperature is 800°C, the carbonization ...

Embodiment 2

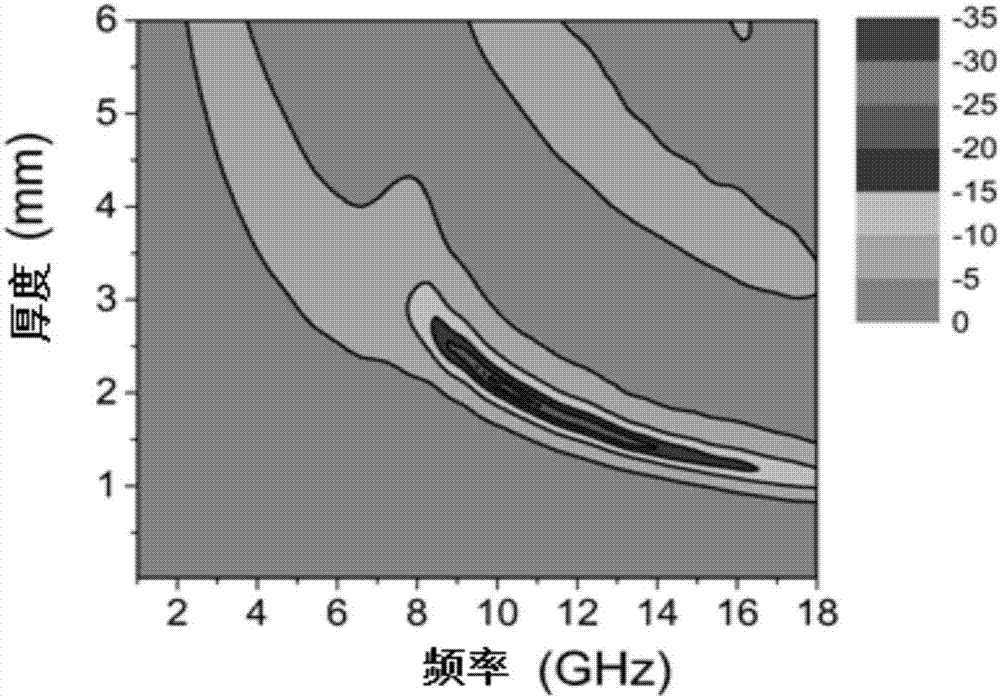

[0034] Using the product of sugar hydrothermal reaction as a precursor, under a protective atmosphere, the specific steps of a carbon-based absorbing material prepared by carbonizing organic matter at a high temperature are as follows:

[0035] (1) Hydrothermal carbonization of sugar: Glucose and deionized water are prepared into a solution at a molar ratio of 1:50, stirred evenly and poured into a polytetrafluoroethylene lining, and the lining is put into a stainless steel reaction kettle, placed in Reaction in a muffle furnace, the reaction temperature is 160°C, and the reaction time is 20 hours, so that the sugar can be fully converted into precursors through organic reactions such as dehydration and polycondensation;

[0036] (2) High-temperature carbonization of precursors: Take an appropriate amount of precursors in a corundum crucible, cover the crucible, and put it into a furnace for high-temperature carbonization. The carbonization temperature is 700°C, the carbonizati...

Embodiment 3

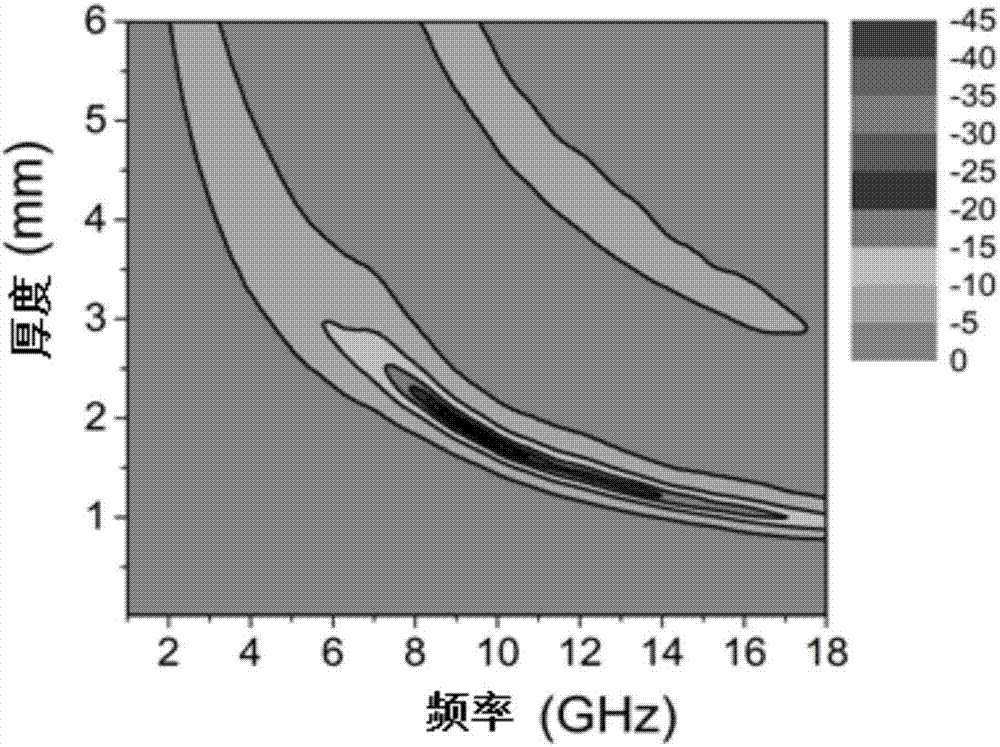

[0041] Using the product of sugar hydrothermal reaction as a precursor, under a protective atmosphere, the specific steps of a carbon-based absorbing material prepared by carbonizing organic matter at a high temperature are as follows:

[0042] (1) Hydrothermal carbonization of sugar: prepare a solution of fructose and deionized water at a molar ratio of 1:250, stir evenly and pour it into a polytetrafluoroethylene lining, put the lining into a stainless steel reaction kettle, place Reaction in a muffle furnace, the reaction temperature is 200°C, and the reaction time is 6 hours, so that the sugar can be fully converted into precursors through organic reactions such as dehydration and polycondensation;

[0043] (2) High-temperature carbonization of precursors: Take an appropriate amount of precursors in a corundum crucible, cover the crucible, and put it into a furnace for high-temperature carbonization. The carbonization temperature is 900°C, the carbonization time is 60min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com