Compound having polymerizable group, liquid crystal composition and liquid crystal display element

A technology of polymerizable groups and compounds, which can be applied to compounds of Group 4/14 elements of the periodic table, organic chemistry, liquid crystal materials, etc. The effect of high retention rate and wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0320] The present invention will be further described in detail through examples (including synthesis examples and use examples). The present invention is not limited by these Examples. The present invention comprises a mixture of the composition of use example 1 and the composition of use example 2. The present invention also includes mixtures prepared by mixing at least two of the compositions of the use examples.

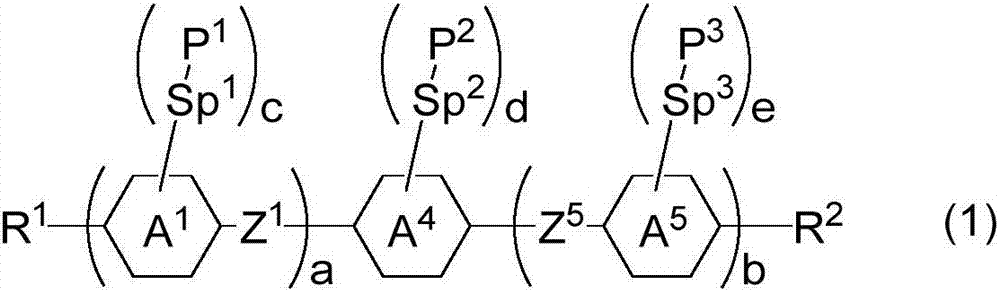

[0321] 1. Examples of compound (1)

[0322] Compound (1) was synthesized in the procedure shown in the Examples. Unless otherwise specified, the reaction was performed under a nitrogen atmosphere. Compound (1) was synthesized in the procedure shown in Example 1 and the like. The synthesized compounds are identified by nuclear magnetic resonance (nuclear magnetic resonance, NMR) analysis and other methods. The properties of compound (1), liquid crystal compound, composition, and device were measured by the following methods.

[0323] NMR analysis: DRX-500 m...

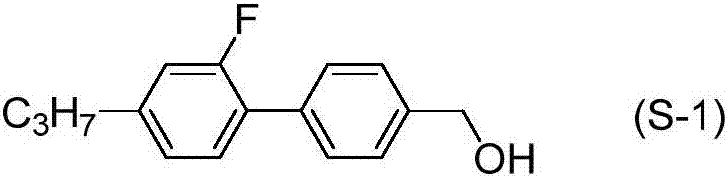

Synthetic example 1

[0370] Synthesis of compound (1-1-10)

[0371]

[0372] Step 1

[0373] Compound (T-1) (4.98g), compound (T-2) (5.00g), potassium carbonate (6.88g), tetrakis (triphenylphosphine) palladium (0.289g) and isopropanol (IsoPropyleAlcohol , IPA) (100ml) was added to the reactor, and heated to reflux at 80° C. for 2 hours. The reaction mixture was poured into water, neutralized with 1N hydrochloric acid, and then extracted with ethyl acetate. The combined organic layer was washed with brine, and dried with anhydrous magnesium sulfate. The solution was concentrated under reduced pressure, and the residue was purified by silica gel chromatography (volume ratio, toluene) to obtain Compound (T-3) (6.38 g; 99%).

[0374] Step 2

[0375] Sodium borohydride (1.88g) and methanol (90ml) were added to the reactor and cooled to 0°C. A solution of compound (T-3) (6.38 g) in tetrahydrofuran (THF) (40 ml) was slowly added dropwise thereto, followed by stirring for 8 hours while returning t...

Synthetic example 2

[0381] Synthesis of compound (1-9-16)

[0382]

[0383] Step 1

[0384] Ethylene glycol (25g), 3,4-dihydro-2H-pyran (33.88g), pyridinium p-toluenesulfonate (2.53g) and dichloromethane (200ml) were added to the reactor, at room temperature Stir for 5 hours. The reaction mixture was poured into water, and extracted with dichloromethane. The combined organic layer was washed with brine, and dried with anhydrous magnesium sulfate. The solution was concentrated under reduced pressure, and the residue was purified by silica gel chromatography (volume ratio, heptane:ethyl acetate=2:1) to obtain compound (T-5) (27.67 g; 47%).

[0385] Step 2

[0386] 2-Hydroxyphenyl acetate (25 g), tetrabutylammonium bromide (79.2 g) and methanol (250 ml) were added to the reactor and stirred at room temperature for 18 hours. The reaction mixture was concentrated under reduced pressure, and the residue was purified by silica gel chromatography (volume ratio, heptane:ethyl acetate=2:1) to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com