Mesoporous P25 titanium dioxide microspheres and preparation method thereof

A technology of titanium dioxide and P25, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem of incomplete connection interface between rutile and anatase, reduced separation efficiency of photogenerated electrons and holes, and unfavorable material transport and light absorption, to achieve the effects of easy control of reaction conditions, improved separation efficiency, and easy repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

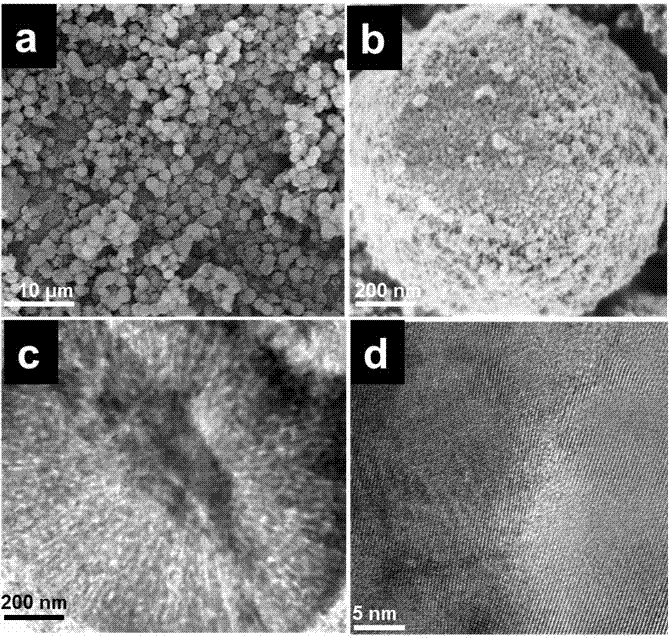

[0025] Example 1: Synthesis of Mesoporous Anatase Titanium Dioxide Microspheres

[0026] Dissolve 1.6g of F127 into 32g of tetrahydrofuran or dioxane solution, stir to obtain a uniform solution (5.0 wt %), add 1.0-3.0g of concentrated sulfuric acid, 1.2-3.6g of glacial acetic acid and stir to form a colorless and transparent solution, then add 2.2-4.8g tetrabutyl titanate was stirred for 0.5-6 h, the solution gradually changed from colorless to golden yellow.

[0027] Transfer the solution to an open glass bottle, transfer the glass bottle to an oven at 20-50°C to volatilize for 8-48 hours, further raise the temperature of the oven to 60-150°C, and volatilize for 2-32 hours to obtain a white powder .

[0028] Put the newly prepared sample in a tube furnace, and bake it at 350°C for 2-6 h under a nitrogen atmosphere, with a heating rate of 0.2-10°C / min, to obtain gray-black TiO 2 / C Composite. The obtained sample was calcined in air at 400°C for 2-5 h to remove the carbon in...

Embodiment 2

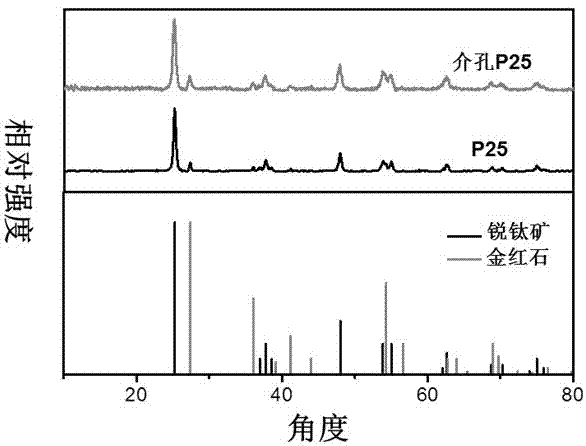

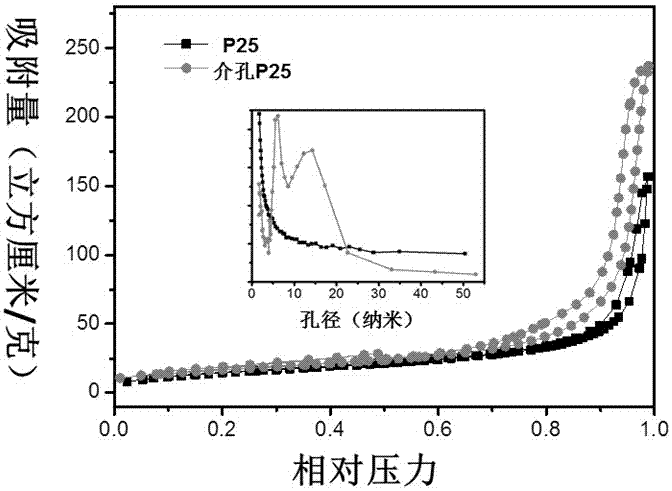

[0029] Example 2: Synthesis of Mesoporous P25 Titanium Dioxide Microspheres

[0030] Dissolve 1.6g F127 into 32g tetrahydrofuran or dioxane solution, stir to obtain a uniform solution (5.0 wt %), add 1.0-3.0g concentrated hydrochloric acid, 1.2-3.6g glacial acetic acid and stir to form a colorless transparent solution, then add 2.2-4.8g of tetrabutyl titanate was stirred for 0.5-6 h, and the solution gradually changed from colorless to golden yellow.

[0031] Transfer the solution to an open glass bottle, transfer the glass bottle to an oven at 20-50°C to volatilize for 8-48 h, further raise the temperature of the oven to 60-150°C, and volatilize for 2-32 hours to obtain White powder.

[0032] Put the newly prepared sample in a tube furnace, and bake it at 350°C for 2-6 h under a nitrogen atmosphere, with a heating rate of 0.2-10°C / min, to obtain gray-black TiO 2 / C Composite. The obtained samples were calcined in air at 400 °C for 2-5 h to remove the carbon, and the mesopor...

Embodiment 3

[0033] Example 3: Synthesis of Mesoporous Rutile Titanium Dioxide Microspheres

[0034] Dissolve 1.6g of F127 into 32g of tetrahydrofuran or dioxane solution, stir to obtain a uniform solution (5.0 wt%), add 3.0-6.0g of concentrated hydrochloric acid, 3.0-6.0g of glacial acetic acid and stir to form a colorless transparent solution, and then Add 2.2-4.8g tetrabutyl titanate and stir for 0.5-6 h, the solution gradually changes from colorless to golden yellow.

[0035] Transfer the solution to an open glass bottle, transfer the glass bottle to an oven at 20-50°C to volatilize for 8-24 hours, further raise the temperature of the oven to 60-100°C, and volatilize for 2-8 hours to obtain white powder.

[0036] Put the newly prepared sample in a tube furnace, and bake it at 350°C for 2-6 h under a nitrogen atmosphere, with a heating rate of 0.2-10°C / min, to obtain gray-black TiO 2 / C Composite. The obtained sample was calcined in air at 400°C for 2-5 h to remove the carbon in it a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Photocurrent | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com