Recycling treatment method for p-aminophenol production waste water

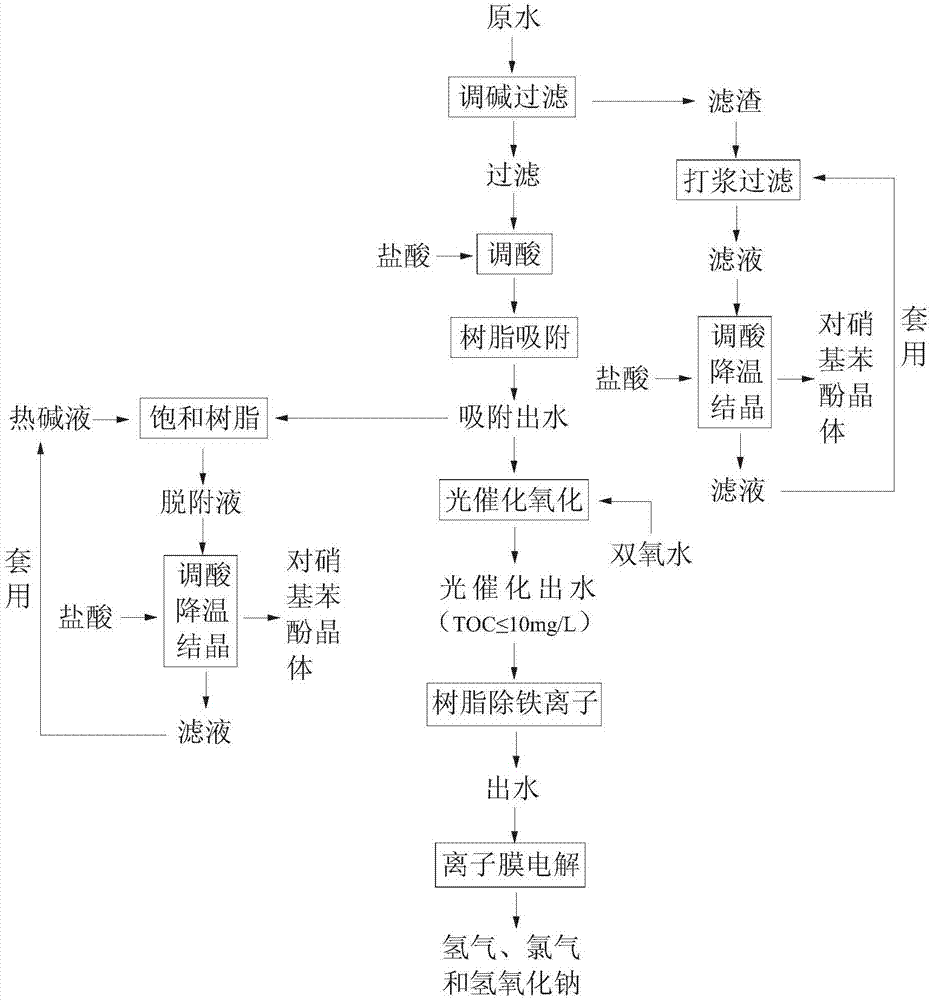

A technology for p-aminophenol and waste water production, applied in water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problems of inability to recover p-nitrophenol, incomplete recovery of nitrophenol, and high energy consumption for evaporation , to achieve the effect of resource recycling, industrial application, and simple operation of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The waste water is produced in the process of p-nitrochlorobenzene prepared by alkali hydrolysis, acidification and crystallization to obtain p-aminophenol products, and then reduced by iron powder. The waste water is yellow, and the TOC is 2033mg / L, [H + ] is 0.4mol / L, the iron ion concentration is 924mg / L, and the concentration of p-nitrophenol is 2000mg / L.

[0050] (1) Add sodium hydroxide solution (30w.t.%) to p-nitrophenol wastewater to carry out neutralization and flocculation, adjust the wastewater pH value to 8.5, add 0.1% powdered activated carbon, stir, flocculate, filter, and the iron ion concentration in the filtrate Reduced to 18mg / L, the wastewater TOC dropped to 1553mg / L, the removal rate was 30.9%, and the generated filter residue accounted for 1.38% of the wastewater quality;

[0051] (2) Utilize (50 times solid waste quality) (60 ℃) hot water to beat and filter the filter residue, and then use concentrated hydrochloric acid (36w.t.%) to adjust the pH v...

Embodiment 2

[0058] The waste water is produced in the process of p-nitrochlorobenzene prepared by alkali hydrolysis, acidification and crystallization to obtain p-aminophenol products, and then reduced by iron powder. The waste water is yellow, and the TOC is 2420mg / L, [H + ] is 0.24mol / L, the iron ion concentration is 864mg / L, and the concentration of p-nitrophenol is 2109mg / L.

[0059] (1) Add sodium hydroxide solution (30w.t.%) to p-nitrophenol wastewater to carry out neutralization and flocculation, adjust the wastewater pH value to 8.8, add 0.2% powdered activated carbon, stir, flocculate, filter, and the iron ion concentration in the filtrate Reduced to 15mg / L, the wastewater TOC dropped to 1672.22mg / L, the removal rate was 30.9%, and the resulting filter residue accounted for 1.41% of the wastewater quality;

[0060] (2) Utilize (50 times solid waste quality) (60 ℃) hot water to beat and filter the filter residue, and then use concentrated hydrochloric acid (36w.t.%) to adjust the ...

Embodiment 3

[0067] The waste water is produced in the process of p-nitrochlorobenzene prepared by alkali hydrolysis, acidification, and crystallization to obtain p-aminophenol products through iron powder reduction. The waste water is yellow, and the TOC is 1862mg / L, [H + ] is 0.52mol / L, the iron ion concentration is 986mg / L, and the concentration of p-nitrophenol is 1833mg / L.

[0068] (1) Add sodium hydroxide solution (30w.t.%) to p-nitrophenol wastewater to carry out neutralization and flocculation, adjust the wastewater pH value to 9, add 0.1% powdered activated carbon, stir, flocculate, filter, and the iron ion concentration in the filtrate Reduced to 15mg / L, the wastewater TOC dropped to 1340.64mg / L, the removal rate was 28%, and the resulting filter residue accounted for 1.39% of the wastewater quality;

[0069] (2) Utilize (50 times solid waste quality) (60 ℃) hot water to beat and filter the filter residue, and then use concentrated hydrochloric acid (36w.t.%) to adjust the pH val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com