Super-hydrophobic material and method for preparing super-hydrophobic material by using in-situ polymerizing method

A super-hydrophobic, thermal polymerization technology, applied in the direction of repelling liquid fibers, coatings, textiles and papermaking, etc., can solve the problems of complex preparation process, poor durability and high cost, and achieve low preparation cost and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

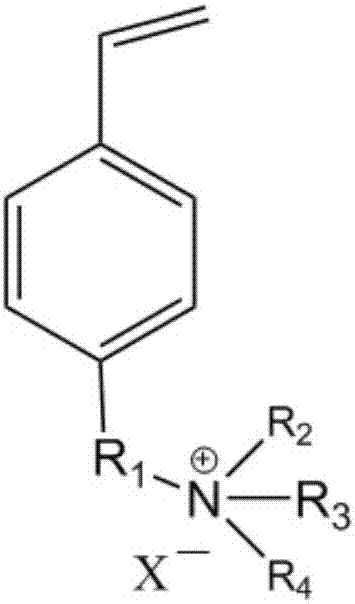

[0037] An ionic liquid precursor with the following molecular formula

[0038]

[0039] Dissolve in dichloromethane to form a solution with a concentration of 1wt%, then add 0.5wt% of 20nm silicon dioxide particles, and ultrasonically disperse for 30min to form a uniform solution; soak the cotton fabric in this solution for 1min and take it out, then Placed in an oven at 120°C for 24 hours. The contact angle of the obtained superhydrophobic material is 155°.

Embodiment 2

[0041] A kind of molecular formula is the ionic liquid precursor of following formula

[0042]

[0043] Dissolve in methanol to form a solution with a concentration of 5wt%, then add 1wt% of 200nm alumina particles, ultrasonically disperse for 30min, and form a uniform solution; soak the copper mesh in this solution for 0.5min, take it out, and then place it at 110 ℃ oven reaction 12h. The contact angle of the obtained superhydrophobic material is 158°.

[0044] The difference between this embodiment and embodiment 1 is that the anion of the ionic liquid monomer is changed to Br - , the length of the longest carbon chain on the cationic group was changed to 16, the dosage was changed to 5wt%, the solvent was changed to methanol, the micro-nano particles were changed to 1wt% of 200nm alumina particles, the base material was changed to copper mesh, and the soaking time was shortened , the oven temperature was lowered, and the reaction time was halved, but the contact angle ...

Embodiment 3

[0046] A kind of molecular formula is the ionic liquid precursor of following formula

[0047]

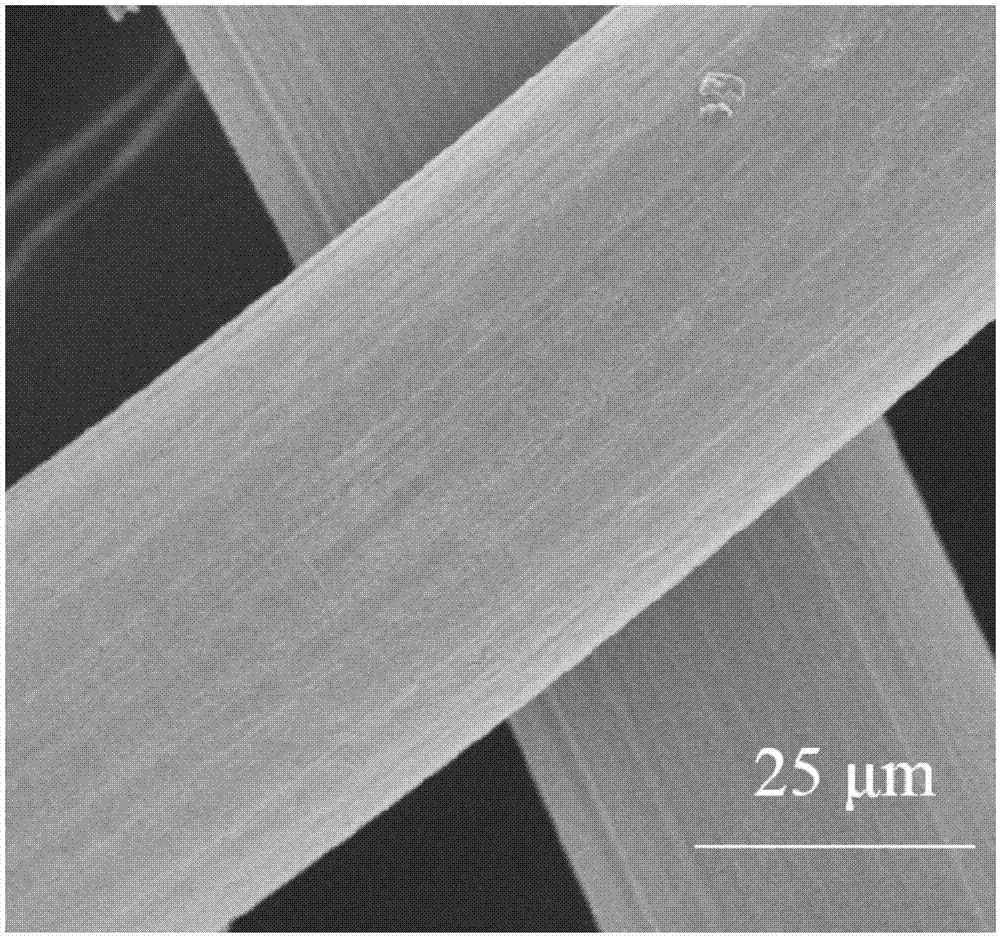

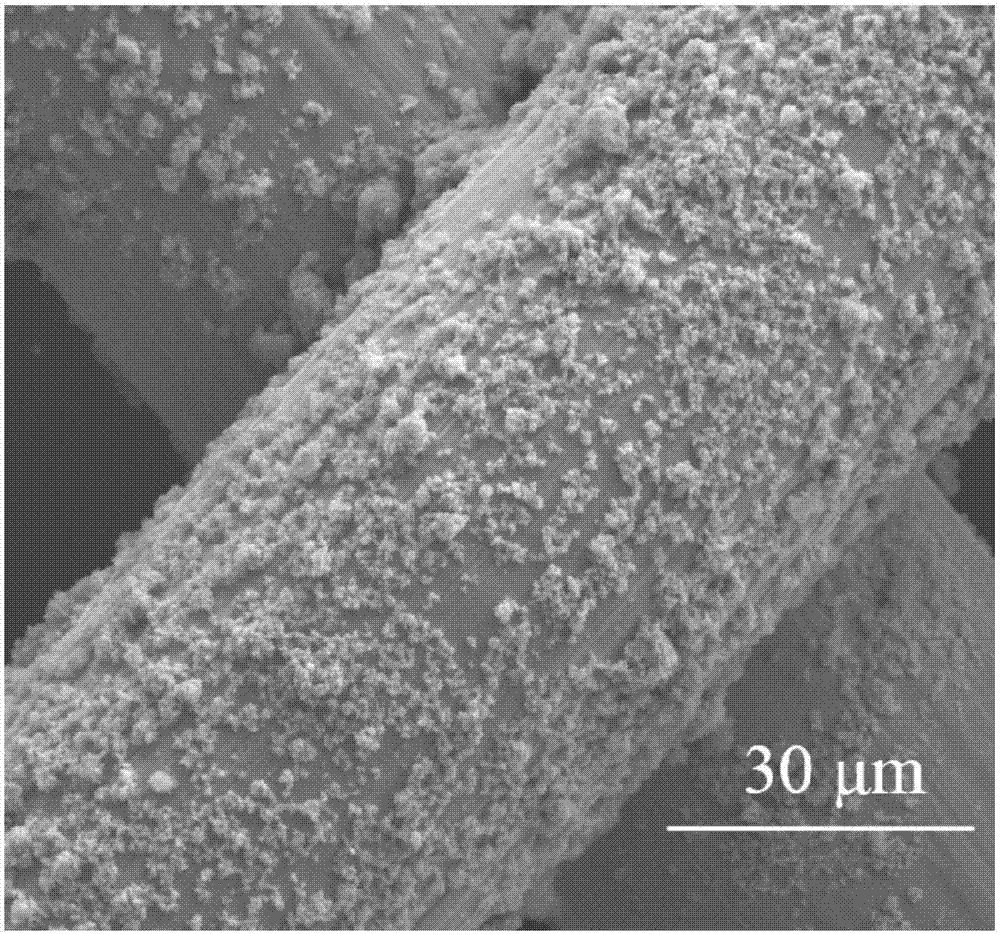

[0048] Dissolve in ethanol to form a solution with a concentration of 10wt%, then add 1wt% of 300nm titanium dioxide particles, ultrasonically disperse for 30 minutes, and form a uniform solution; soak the stainless steel mesh in this solution for 30 minutes, take it out, and then place it in an oven at 150°C Medium reaction 60h. The resulting superhydrophobic metal mesh magnified 2500 times electron microscope picture as attached figure 2 As shown, its contact angle value is 157°.

[0049]The difference between this embodiment and embodiment 2 is that the anion of the ionic liquid monomer is changed to BF 4 - , the dosage is changed to 10wt%, the solvent is changed to ethanol, the base material is changed to stainless steel mesh, the micro-nano particles are changed to 300nm titanium dioxide particles, the soaking time is increased, the oven temperature is increased, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com