Carbon aerogel/metal oxide composite material and preparation method and application thereof

A composite material, carbon aerogel technology, applied in the field of materials, can solve the problems of supercapacitor-battery comprehensive performance materials rarely reported, and achieve enhanced electrochemical performance, improved mass transfer efficiency, and high active sites. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

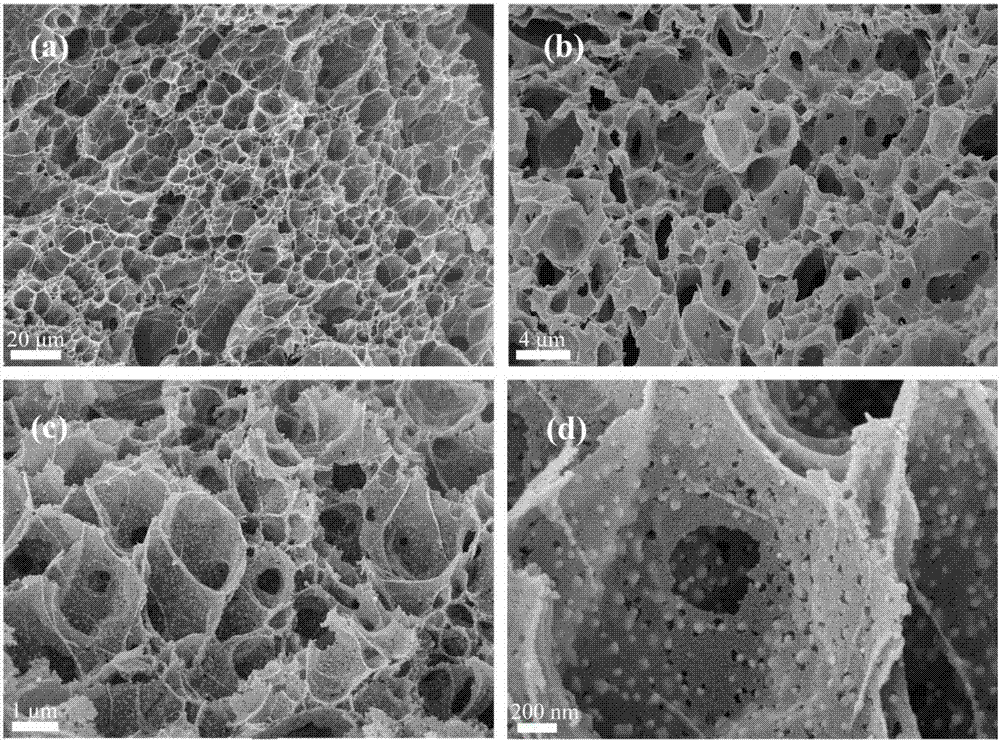

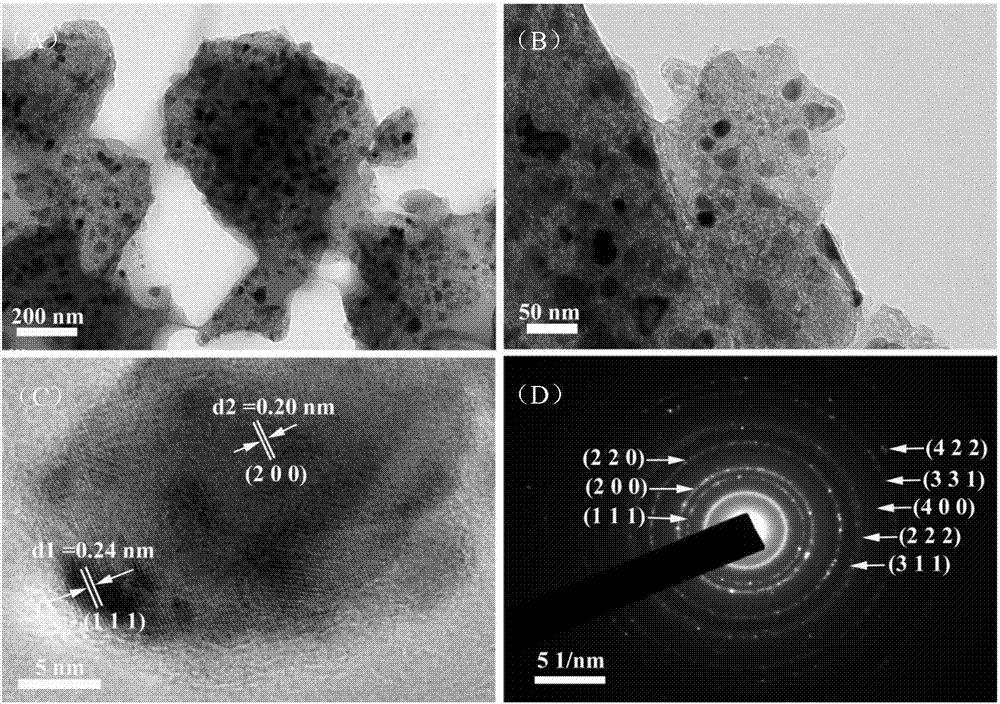

[0029] Example 1: Nitrogen-containing hierarchical porous carbon aerogel / Co 3 o 4 Composite material preparation

[0030] Add 1 g of gelatin to 20 mL of deionized water, stir at 60°C until the gelatin is completely dissolved, then add 0.5 g of polyacrylic acid, and stir evenly to obtain a transparent gelatin-polyacrylic acid sol; while stirring, add 0.3 g of cobalt acetate, wait After the cobalt acetate is completely dissolved, a transparent hydrosol is obtained; keep the hydrosol at about 4°C for 24 hours, and the gelatin-polyacrylic acid sol will undergo self-crosslinking reaction to obtain a transparent hydrogel; the fully crosslinked water The gel was placed in an environment of -4°C and kept for 48 hours, then subjected to graded freezing at 4°C, 0°C, and -20°C in sequence, and then freeze-dried in a freeze dryer at -50°C and less than 10 Pa to obtain A carbon airgel / metal oxide material with a multi-level pore structure; move the carbon airgel / metal oxide material to a...

Embodiment 2

[0032] Example 2: Nitrogen-containing hierarchical porous carbon aerogel / Co 3 o 4 Preparation of composite materials

[0033] Add 1 g of gelatin to 20 mL of deionized water, stir at 60°C until the gelatin is completely dissolved, then add 0.5 g of polyacrylic acid, and stir evenly to obtain a transparent gelatin-polyacrylic acid sol; while stirring, add 0.5 g of cobalt acetate, wait After the cobalt acetate is completely dissolved, a transparent hydrosol is obtained; the hydrosol is placed in an environment at about 4°C for 24 hours, and the hydrosol will undergo a self-crosslinking reaction to obtain a transparent hydrogel; the fully crosslinked hydrogel The gel was kept at -4°C for 48 hours, and the fully cross-linked hydrogel was kept at -4°C for 48 hours, and then graded and frozen at 4°C, 0°C, and -20°C in sequence, and then Freeze-drying in a freeze dryer at -50°C and less than 10Pa to obtain a carbon airgel / metal oxide material with a multi-level pore structure, and t...

Embodiment 3

[0035] Example 3: Nitrogen-containing hierarchical porous carbon aerogel / Co 3 o 4 Preparation of composite materials

[0036] Add 1g of gelatin to 20mL of deionized water, stir at 60°C until the gelatin is completely dissolved, then add 0.5g of polyacrylic acid to obtain a transparent gelatin-polyacrylic acid sol; while stirring, add 0.75g of cobalt acetate until the cobalt acetate is completely dissolved Finally, a transparent hydrosol is obtained; the hydrosol is placed in an environment at about 4°C for 24 hours, and the hydrosol will undergo a self-crosslinking reaction to obtain a transparent hydrogel; the fully crosslinked hydrogel is placed in- In the environment of 4°C, keep it for 48 hours, then carry out hierarchical freezing treatment at 4°C, 0°C, and -20°C in sequence, and then freeze-dry in a freeze dryer at -50°C and less than 10Pa to obtain a multi-level porous structure. Carbon airgel / metal oxide material, then move the above carbon airgel / metal oxide materia...

PUM

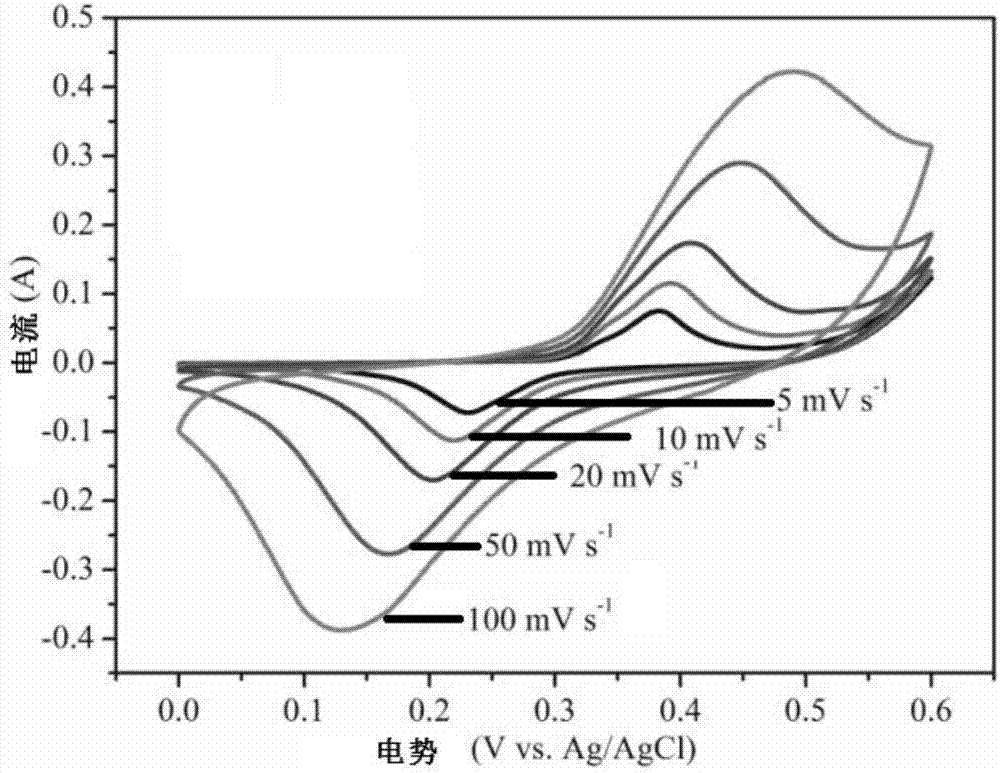

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com