Low-phosphorus and low-sulfur high-strength heat-resistant Cr35Ni45 nichrome welding wire and preparation technology thereof

A nickel-chromium alloy and preparation technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as poor welding technology, low welding quality, and complicated production process, so as to improve oxidation resistance and improve The effect of welding quality and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

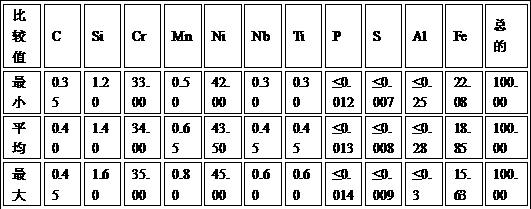

[0033] A low-phosphorus-sulfur high-strength high-temperature-resistant Cr 35Ni 45 Nickel-chromium alloy welding wire, its chemical composition includes the following components in terms of mass percentage: C0.35, Si 1.2%, Cr 33.00%, Mn 0.50%, Ni 42.00%, Nb 0.30%, Ti0.30%, P0.012 %, S0.007%, Al0.25%, Fe 22.08%, and other unavoidable impurity elements.

[0034] The preparation technology of this nickel-chromium alloy welding wire comprises the following steps:

[0035] (1) Vacuum melting: according to the mass percentage of the chemical composition of the welding wire, Ni, Cr, Fe, Mn, Nb are first added to the intermediate frequency furnace for melting, and after the required chemical composition is detected, the medium and high temperature calcium-added aluminum alloy is used Deoxidize and reduce the content of phosphorus and sulfur, then add Ti to achieve the required chemical composition after detection, use the downcasting method to purify the impurities in the material, ...

Embodiment 2

[0043] A low-phosphorus-sulfur high-strength high-temperature-resistant Cr 35 Ni 45 Nickel-chromium alloy welding wire, its chemical composition includes the following components in terms of mass percentage: C0.40, Si1.40%, Cr 34.00%, Mn 0.65%, Ni 43.50%, Nb 0.45%, Ti0.45%, P0. 013%, S0.008%, Al0.28%, Fe 18.85%, and other unavoidable impurity elements.

[0044] The preparation technology of this nickel-chromium alloy welding wire comprises the following steps:

[0045] (1) Vacuum melting: according to the mass percentage of the chemical composition of the welding wire, Ni, Cr, Fe, Mn, Nb are first added to the intermediate frequency furnace for melting, and after the required chemical composition is detected, the medium and high temperature calcium-added aluminum alloy is used Deoxidize and reduce the content of phosphorus and sulfur, then add Ti to achieve the required chemical composition after detection, use the downcasting method to purify the impurities in the material,...

Embodiment 3

[0053] A low-phosphorus-sulfur high-strength high-temperature-resistant Cr 35 Ni 45 Nickel-chromium alloy welding wire, its chemical composition includes the following components in terms of mass percentage: C0.45, Si 1.60%, Cr 35.00%, Mn0.80%, Ni 45.00%, Nb 0.60%, Ti0.60%, P0. 014%, S0.009%, Al0.30%, Fe 15.63%, and other unavoidable impurity elements.

[0054] The preparation technology of this nickel alloy welding wire comprises the following steps:

[0055] (1) Vacuum melting: according to the mass percentage of the chemical composition of the welding wire, Ni, Cr, Fe, Mn, Nb are first added to the intermediate frequency furnace for melting, and after the required chemical composition is detected, the medium and high temperature calcium-added aluminum alloy is used Deoxidize and reduce the content of phosphorus and sulfur, then add Ti to reach the required chemical composition after detection, use the downcasting method to purify the impurities in the material, after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com