Preparation method of directionally growing titanium dioxide nano-cluster array

A titanium dioxide, directional growth technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of industrial production gap and high experimental requirements, and achieve low production cost, good light transmission and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] (1) Pre-patterning of FTO conductive substrate

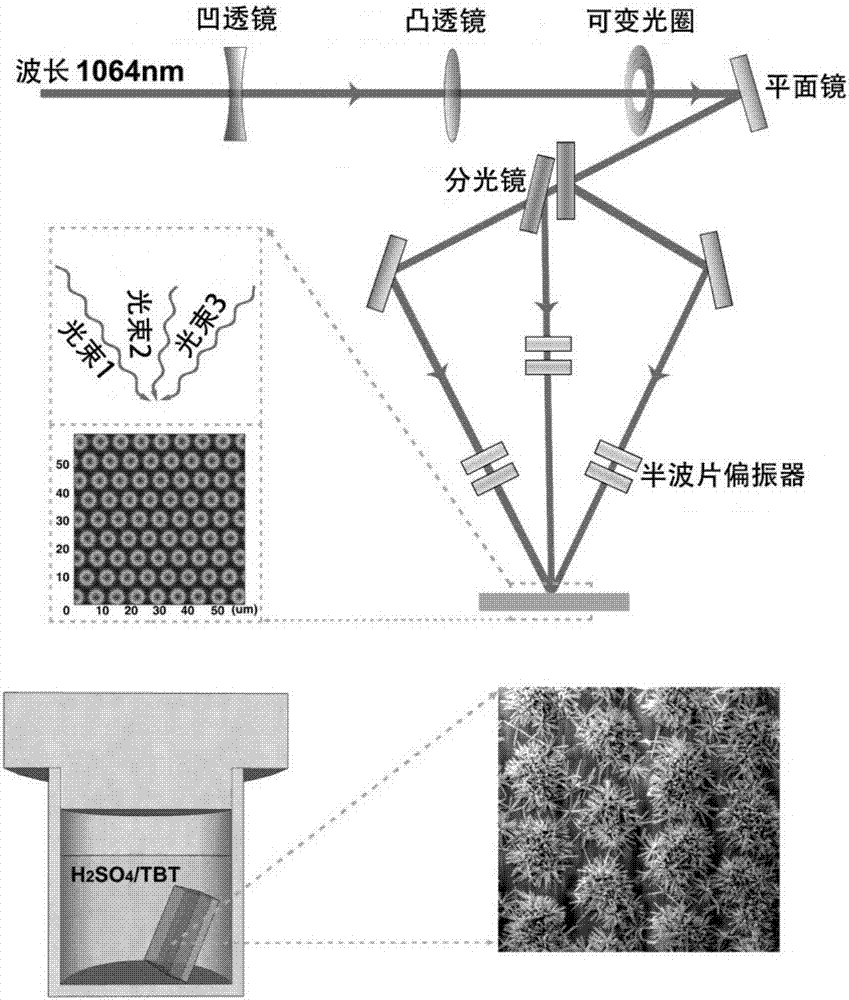

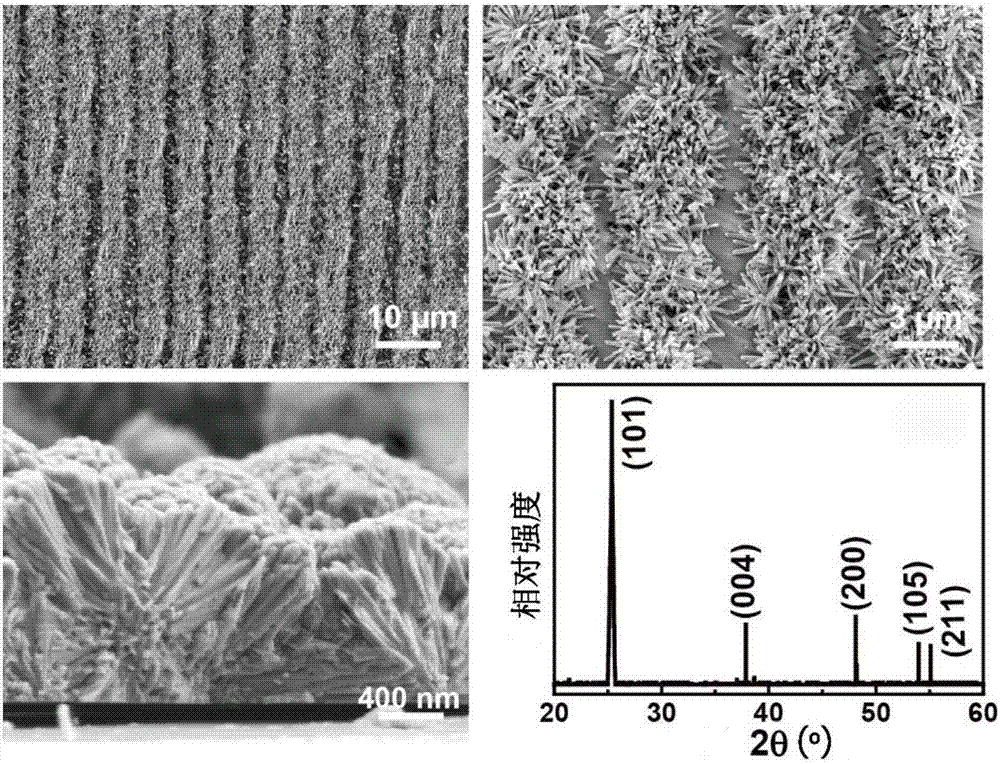

[0027] Set the surface area to 1 cm 2 The FTO conductive substrates were ultrasonically cleaned in acetone, absolute ethanol, and deionized water, each time for 150 s, and dried at room temperature after taking them out. Build a two-beam laser interference optical path system. The two-beam laser interference system is composed of a laser, beam splitting, and refraction. The laser emits a beam of laser light, which is divided into two coherent beams by the beam splitting system. Composed of a beam splitter, a half-wave plate and a polarizer, the two beams of coherent light are spatially symmetrical through the refraction system, so that they irradiate the sample at the same time at an incident angle of 3°, the exposure energy is 80mJ, and the exposure time is 1s. By changing the two-beam spatial light interference parameters, including spatial angle, incident angle, phase angle, polarization state, interference light inte...

Embodiment 2

[0032] (1) Pre-patterning of FTO conductive substrate

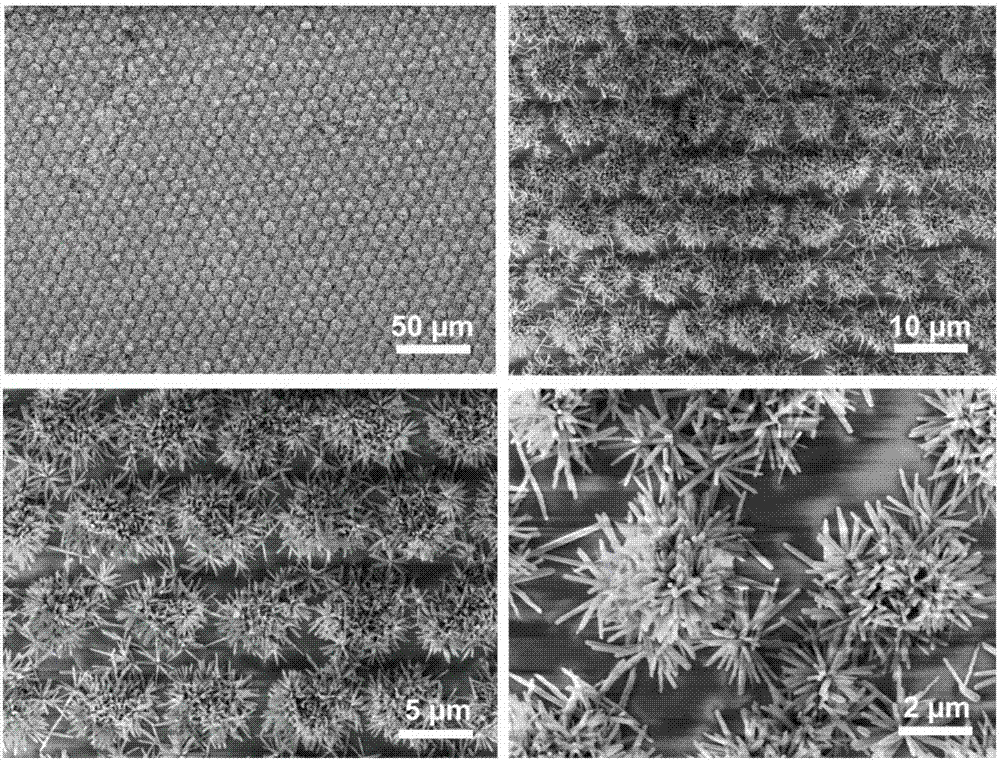

[0033] Set the surface area to 1 cm 2 The FTO conductive substrates were ultrasonically cleaned in acetone, absolute ethanol, and deionized water, each time for 150 s, and dried at room temperature after taking them out. Build a three-beam laser interference optical path system. The three-beam laser interference system is composed of a laser, beam splitter, and refraction. The laser emits a beam of laser light, which is divided into three beams of coherent beams by the beam splitter system. The beam splitter system is composed of high reflection mirrors, Composed of a beam splitter, a half-wave plate and a polarizer, the three beams of coherent light are spatially symmetrical through the refraction system, so that they irradiate the sample at the same time at an incident angle of 8.5°, the exposure energy is 60mJ, and the exposure time is 1s. By changing the three beams of spatial light Interference parameters, parameter...

Embodiment 3

[0038] (1) Pre-patterning of FTO conductive substrate

[0039] Set the surface area to 2cm 2 The FTO conductive substrates were ultrasonically cleaned in acetone, absolute ethanol, and deionized water, each time for 150 s, and dried at room temperature after taking them out. Build a two-beam laser interference optical path system. The two-beam laser interference system is composed of a laser, beam splitting, and refraction. The laser emits a beam of laser light, which is divided into two coherent beams by the beam splitting system. Composed of a beam splitter, a half-wave plate and a polarizer, the refraction system makes the two beams of coherent light spatially symmetrical, so that they irradiate the sample at the same time at an incident angle of 4°, the exposure energy is 85mJ, and the exposure time is 1s. By changing the two-beam spatial light interference parameters, including spatial angle, incident angle, phase angle, polarization state, interference light intensity a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com