Preparation method and application of polyester titanium catalyst

A technology of titanium-based catalyst and polyester, which is applied in the field of synthesis of titanium-based catalysts for polyester preparation, and can solve problems such as polyester yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

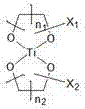

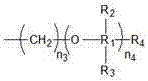

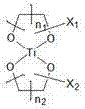

Method used

Image

Examples

Embodiment 1

[0049] Titanium Catalyst I 1 preparation of

[0050] Add diethylene glycol monomethyl ether (5.94g, 49.44mmol), p-toluenesulfonyl chloride (7.85g, 41.20mmol), and potassium carbonate (22.78g, 164.80mmol) into a mortar. Cover with plastic wrap to isolate oxygen, grind for 10 minutes, and place until no heat release (about 4 hours) to obtain a reaction mixture. Dissolve the mixture with dichloromethane, filter the suspension containing the mixture, take the liquid phase and dry it with anhydrous magnesium sulfate, filter the liquid phase, and remove the solvent by rotary evaporation to obtain the product A 1 (9.11 g), yield 80.6%. The reaction formula is as follows:

[0051] .

[0052] Add acetonide (4.61g, 34.87mmol) to the three-necked flask under nitrogen protection, dissolve it in 60mL of anhydrous tetrahydrofuran (THF), put it in an ice-water bath, add sodium hydride (60% dispersed in kerosene, 2.09g, 52.30 mmol). After 30min, the temperature was raised to 40°C, and...

Embodiment 2

[0059] Titanium Catalyst I 2 preparation of

[0060] Add ethylene glycol monomethyl ether (4.00 g, 52.04 mmol), p-toluenesulfonyl chloride (8.27 g, 43.36 mmol), and potassium carbonate (23.98 g, 173.47 mmol) into a mortar. Cover with plastic wrap to isolate oxygen, grind for 10 minutes, and place until no longer exothermic (about 4 hours). Dissolve the mixture with dichloromethane, filter the liquid phase, dry with anhydrous magnesium sulfate, filter the liquid phase, remove the solvent by rotary evaporation, and weigh the product A 2 (8.39 g), yield 84.0%. The reaction formula is as follows:

[0061] .

[0062] Add acetonide (5.06g, 38.26mmol) to the three-necked flask under nitrogen protection, dissolve it in 60mL of anhydrous tetrahydrofuran (THF), put it in an ice-water bath, add sodium hydride (60% dispersed in kerosene, 2.29g, 57.38 mmol). After 30min, the temperature was raised to 40°C, and the product A 2 (8.39g, 36.44mmol) was dissolved in anhydrous THF, drop...

Embodiment 3

[0069]Preparation of polyester

[0070] Mix 500 grams of purified terephthalic acid and 246 grams of ethylene glycol to form a slurry, add it to a polymerization kettle, and carry out esterification reaction. The esterification temperature is 240-250 ° C, the pressure is 0.25 MPa, and it is discharged through a rectification device. water produced by the reaction. After the esterification is finished, it is lowered to normal pressure, and the catalyst I is added 1 , the amount of catalyst is based on the quality of the polyester produced, the mass ratio of titanium atoms is 1.35ppm, vacuumize and depressurize until the system pressure is lower than 150Pa, at the same time, the reaction temperature gradually rises to 280°C, stop the reaction after the intrinsic viscosity reaches the standard, and then put The reaction product is continuously extruded in strip form from the bottom of the polymerization tank, cooled and cut into pellets, and the polyester product is dried, cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com