Environment-friendly three-element catalytic detergent

A cleaning agent and an environment-friendly technology, which is applied in the field of preparation of an environment-friendly three-way catalytic cleaning agent, can solve problems such as difficult biodegradation, three-way catalyst poisoning and deactivation, and delayed ignition time, and achieve good biodegradability and improved catalytic performance. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

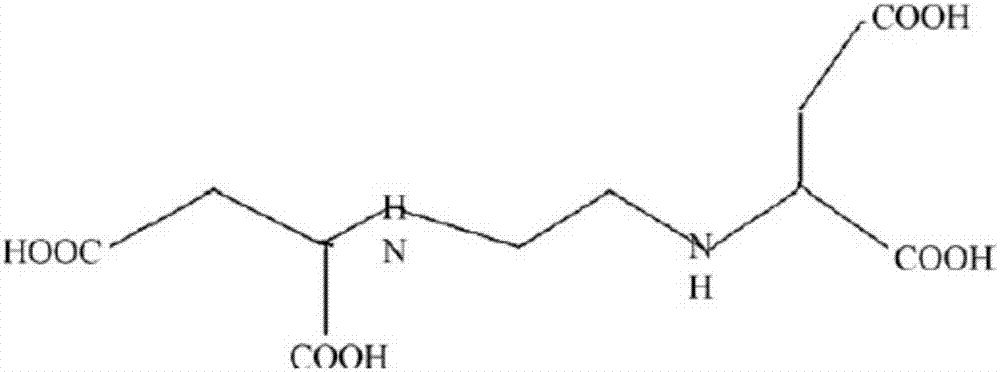

[0058] Select the raw material of following weight percentage content: the hydrochloric acid of 0.5wt%, the S of 10wt%, S-EDDS, by the fatty acid diethanolamine of the alkyl phosphate of 2wt%, the polyethylene glycol monoalkyl ether of 2wt% and 2wt% The cleaning agent of composition, the hydroxyethylidene diphosphonic acid of 5wt%, the cosolvent of 5wt%, and the deionized water of 73.5wt% are described hydrochloric acid, described EDDS, described cleaning agent, described hydroxyethylidene diphosphonic acid Phosphonic acid, the co-solvent, and deionized water were uniformly mixed to obtain the three-way catalyst cleaning agent of this embodiment.

[0059] The three-way catalytic cleaning agent of Example 1 was used on an old Audi whose three-way catalytic converter was blocked and could not be started normally. The application method is:

[0060] Remove the three-way catalytic converter together with the oxygen sensor, place the dismantled three-way catalytic converter in the...

Embodiment 2

[0067] Choose the raw material of following weight percentage content: the hydrochloric acid of 0.65wt%, the S of 15wt%, S-EDDS, by the alkyl phosphate of 3.5wt%, the polyethylene glycol monoalkyl ether of 3.5wt% and the 3.5wt% The detergent composed of fatty acid diethanolamine, 10wt% scale and corrosion inhibitor, 5wt% cosolvent, and 58.85wt% deionized water, the hydrochloric acid, the EDDS, the detergent, the scale inhibitor The corrosion inhibitor and deionized water were evenly mixed to obtain the three-way catalyst cleaning agent of this embodiment.

Embodiment 3

[0069] Choose the raw material of following weight percentage content: the hydrochloric acid of 0.8wt%, the S of 20wt%, S-EDDS, by the fatty acid diethanolamine of the alkyl phosphate of 5wt%, the polyethylene glycol monoalkyl ether of 5wt% and 5wt% The cleaning agent of composition, the scale and corrosion inhibitor of 15wt%, the co-solvent of 5wt%, and the deionized water of 44.2wt%, described hydrochloric acid, described EDDS, described cleaning agent, described scale and corrosion inhibitor and deionized water are mixed evenly to obtain the three-way catalyst cleaning agent of the present embodiment.

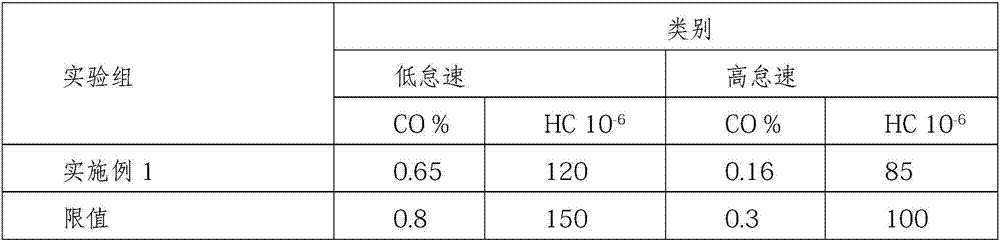

[0070] The cleaning agents of Example 1, Example 2 and Example 3 were applied to the Toyota Highlander with 70,000 kilometers, the Honda Fit with 60,000 kilometers and the Roewe car with 60,000 kilometers.

[0071] The application method is: first start the engine, and turn off the engine after the water temperature is normal; connect the hanging bottle containing the cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com