Method for preparing high-quality large-size two-dimensional material

A two-dimensional material, large-scale technology, which is applied in the field of liquid-phase separation to prepare high-quality large-scale two-dimensional materials, can solve the problems that two-dimensional materials are not suitable for large-scale preparation, the performance difference of two-dimensional materials, and the deterioration of intrinsic properties, etc. To achieve the effect of shortening peeling time, increasing productivity and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

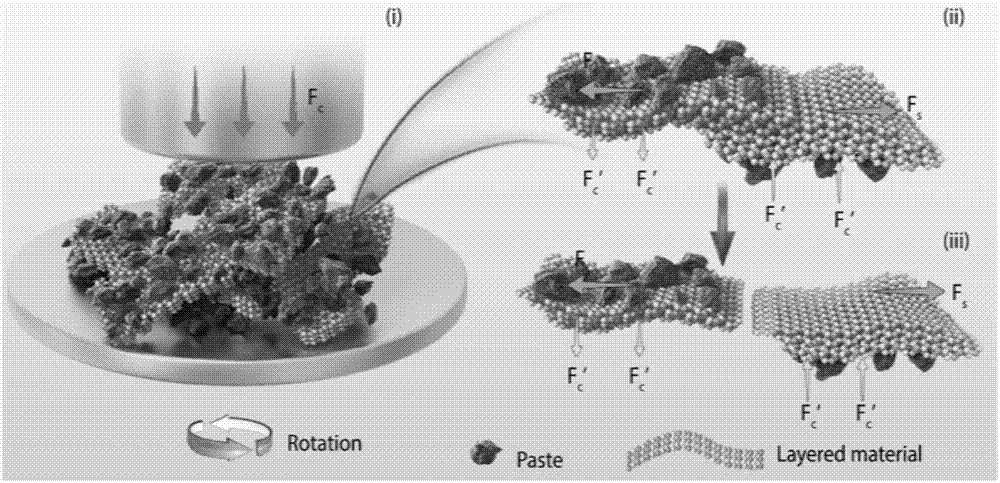

Method used

Image

Examples

Embodiment 1

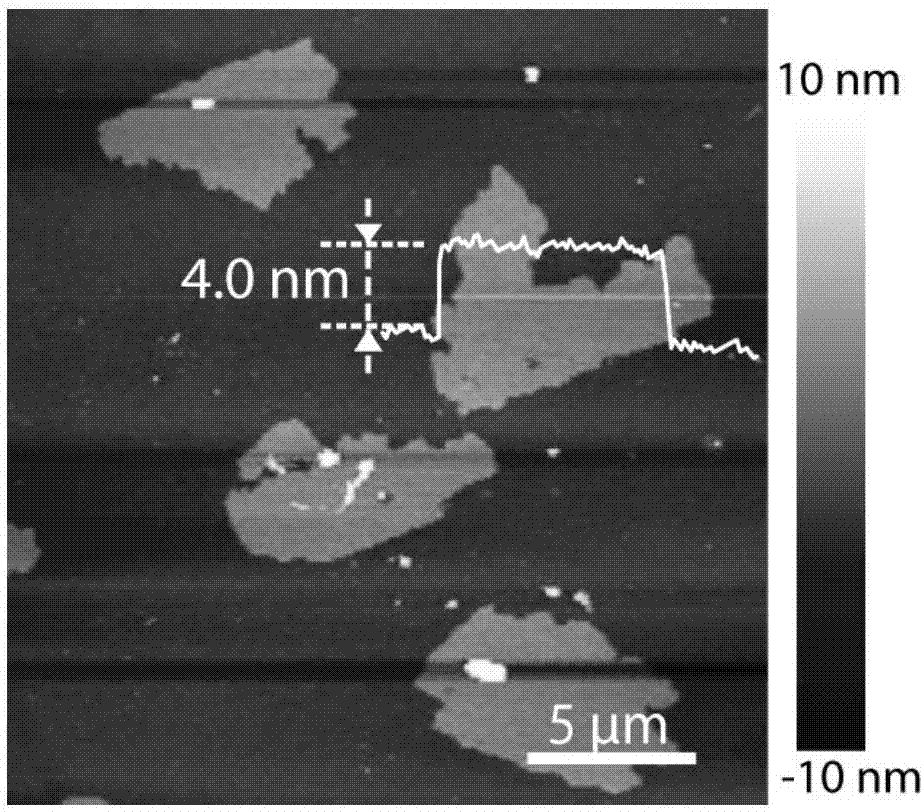

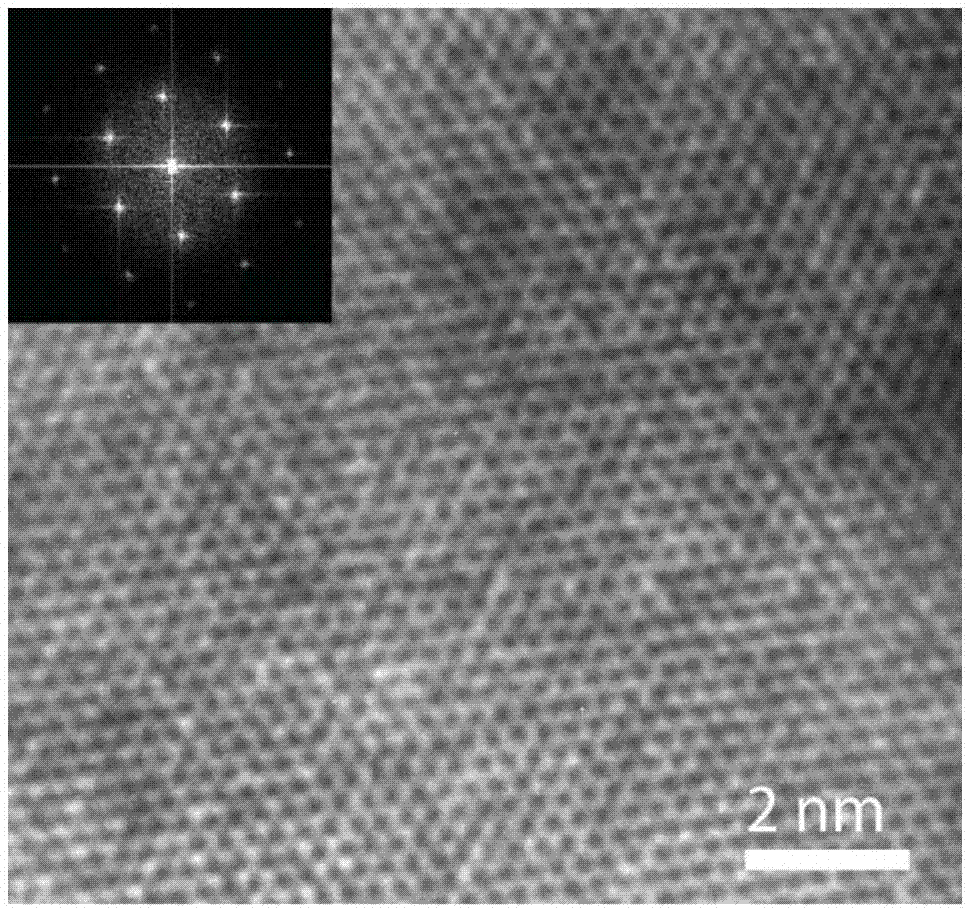

[0034] Mix layered boron nitride and 400-mesh resin sand evenly at a ratio of 100:1, then add it to the mortar grinder, and apply 100N / cm to the mortar rod 2 Squeeze and grind with the active force, grind for 5 hours to obtain the stripped layered boron nitride, then put the stripped layered boron nitride into the SDS aqueous solution, shake well, then centrifuge at 1000rpm for 10min to precipitate, take the supernatant, A high-quality and large-size boron nitride two-dimensional material dispersion is obtained. figure 2 The AFM figure of the boron nitride two-dimensional material prepared for this embodiment, image 3 It is the HR-TEM image of the boron nitride two-dimensional material prepared in this example. Depend on figure 2 and image 3 It can be seen that the thickness of the boron nitride two-dimensional material is about 4 nm, and its lateral dimension is about 3-12 μm.

Embodiment 2

[0036] On the basis of Example 1, this example designs the grinding time of the mortar and rod, which are 10 minutes, 5 hours, and 100 hours, respectively. The photo of the dispersion liquid of the obtained boron nitride two-dimensional material is as follows Figure 4 shown.

Embodiment 3

[0038] On the basis of Example 1, this example designs the mass ratios of resin sand to layered boron nitride, which are 1:100, 1:10, 10:1, and 100:1, respectively. The photo of the dispersion liquid of the obtained boron nitride two-dimensional material is as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com