Flame-retarding functionalized phase-change composite material

A phase change composite material and phase change energy storage material technology, applied in the field of building materials, can solve problems such as low thermal conductivity and only 0.36-0.42 thermal conductivity, reduce building energy consumption, increase self-temperature regulation function, and improve human comfort sense of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

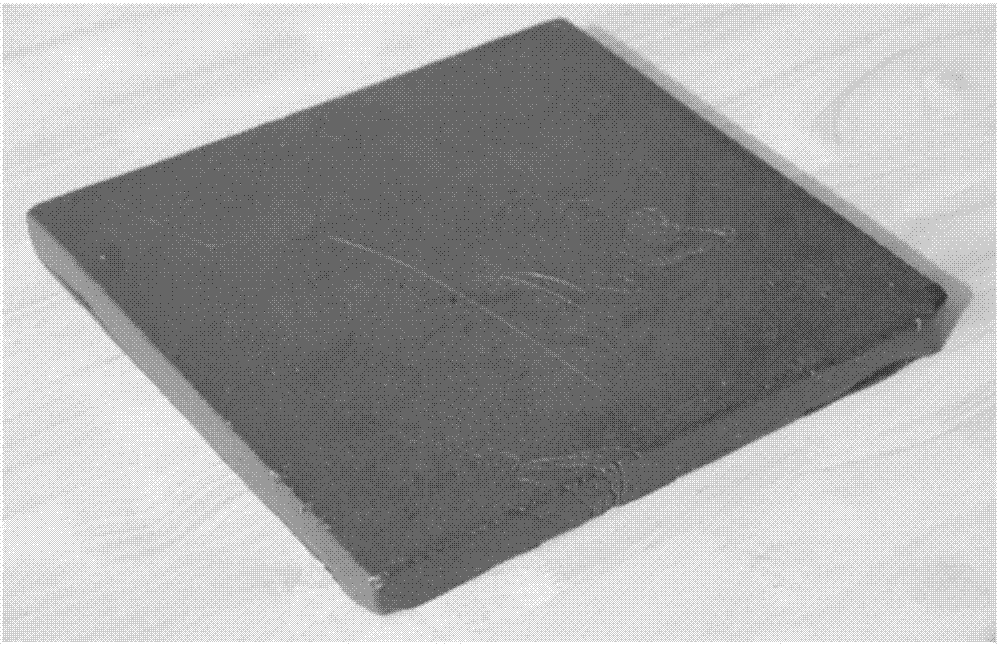

Embodiment 1

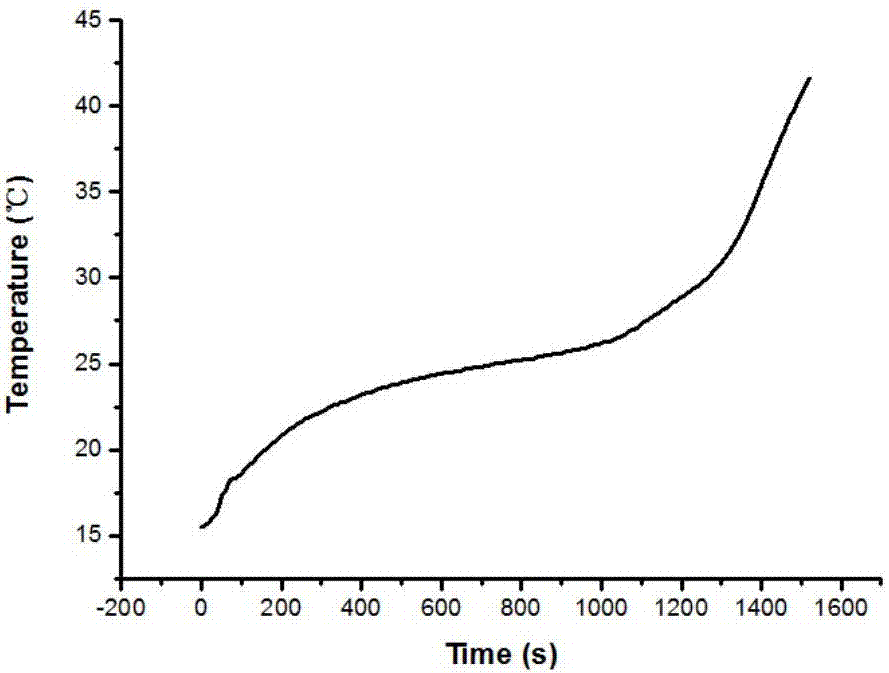

[0032] Embodiment 1. 5kg of paraffin and 0.5kg of expanded graphite were mixed at 60°C. Add the obtained material to the mixing system, add 2kg polyethylene, 0.2kg styrene-ethylene / butylene-styrene, 0.02kg copper oxide, 0.02kg stabilizer and 0.2kg ethylene vinyl acetate copolymer, at 160°C Stir slowly to combine. After mixing evenly, lower the temperature to 130°C, and slowly add 0.7kg of expandable graphite, and a mixture of 0.2kg of melamine, 0.6kg of ammonium polyphosphate, 0.5kg of pentaerythritol and 0.06kg of nano-montmorillonite in order. The functionalized phase-change composite material obtained by hot-pressing at 150°C using a pressing process can pass the flame retardant test of GB / T 11785 and GB / T 8626 standards, and when a standard sunlight is irradiated (100mW / cm 2 ) has a photothermal conversion efficiency greater than 70%, a thermal conductivity of 1.1W / mK measured by a laser thermal conductivity meter, a melting point of 20°C measured by a differential scanni...

Embodiment 2

[0033] Example 2, 5.7kg of a formulation of methyl palmitate and methyl stearate and 0.5kg of graphite were mixed at 80°C. The obtained material was slowly kneaded at 180° C. with 2 kg of high-density polyethylene, 0.3 kg of styrene-ethylene / butylene-styrene and 0.2 kg of ethylene-vinyl acetate copolymer. After mixing evenly, slowly add a mixture of 0.5kg of expandable graphite, 0.5kg of ammonium polyphosphate, and 0.3kg of melamine, and mix evenly again at 150°C. Formed at 160°C by pressing process, the obtained functionalized phase change composite material can pass the flame retardant test of GB / T 11785 and GB / T 8626 standards, under a standard sunlight irradiation (100mW / cm 2 ) has a photothermal conversion efficiency greater than 70%, a thermal conductivity of 1.4W / mK measured by a laser thermal conductivity meter, a melting point of 22°C measured by a differential scanning calorimeter, and a phase change enthalpy of 92.1kJ / kg.

Embodiment 3

[0034] Embodiment three, 4kg methyl hexadecanoate and 0.8kg expanded graphite are mixed uniformly at 80 ℃; Graphite, 0.1kg chlorinated paraffin, 0.2kg antimony trioxide and 0.3kg aluminum hydroxide were mixed in a high-speed mixer to 60°C. The functionalized phase-change composite material is obtained by extruding at 180°C. Its flame retardant test can pass GB / T 11785 and GB / T 8626 standards, under a standard sunlight irradiation (100mW / cm 2) has a photothermal conversion efficiency greater than 70%, a thermal conductivity of 1.8W / mK measured by a laser thermal conductivity meter, a melting point of 24°C measured by a differential scanning calorimeter, and a phase change enthalpy of 60.3kJ / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com