High-plasticity and biodegradable Zn-Mn-system zinc alloy and preparation method thereof

A biodegradable, zinc alloy technology, applied in tissue regeneration, medical science, prosthesis, etc., to achieve the effects of reducing fat content in the liver, high plasticity, and promoting growth recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

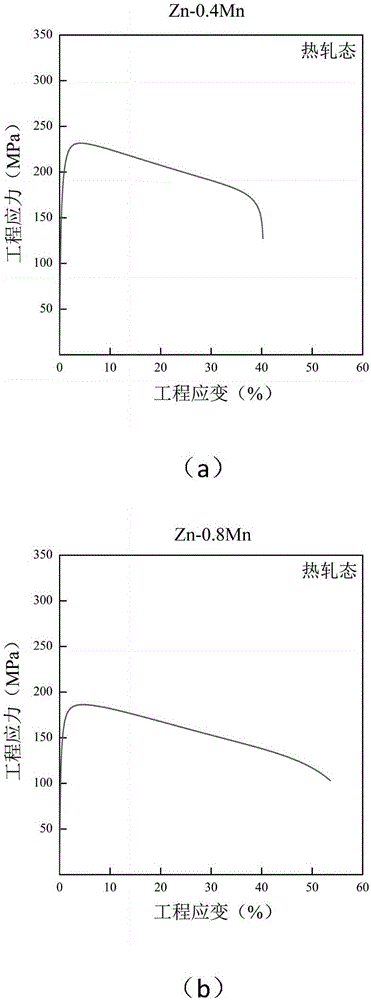

[0039] The hot-rolled Zn-Mn alloy sheet was prepared and the mechanical and corrosion properties of the material were measured.

[0040] The process flow is: raw material preparation and batching→alloy smelting and casting→homogenizing annealing→hot rolling→finished plate.

[0041] Using pure Zn (99.99%) and pure Mn (99.9%) as raw materials, mixed according to the following two mass percentages, put into the Al in the vacuum induction melting furnace 2 o 3 In the crucible: (1) 99.2% Zn and 0.8% Mn (2) 99.6% Zn and 0.4% Mn. Vacuumize first, and then introduce argon after the pressure in the vacuum induction melting furnace reaches 30Pa, so that the pressure of argon reaches 0.04MPa. The Al containing raw material was then heated under the protection of argon 2 o 3 The crucible was refined at 760°C for 5 minutes, and then the alloy melt was poured into a cylindrical high-purity graphite mold with a diameter of 75 mm, and cooled to room temperature in air to prepare Zn-0.8Mn ...

Embodiment 2

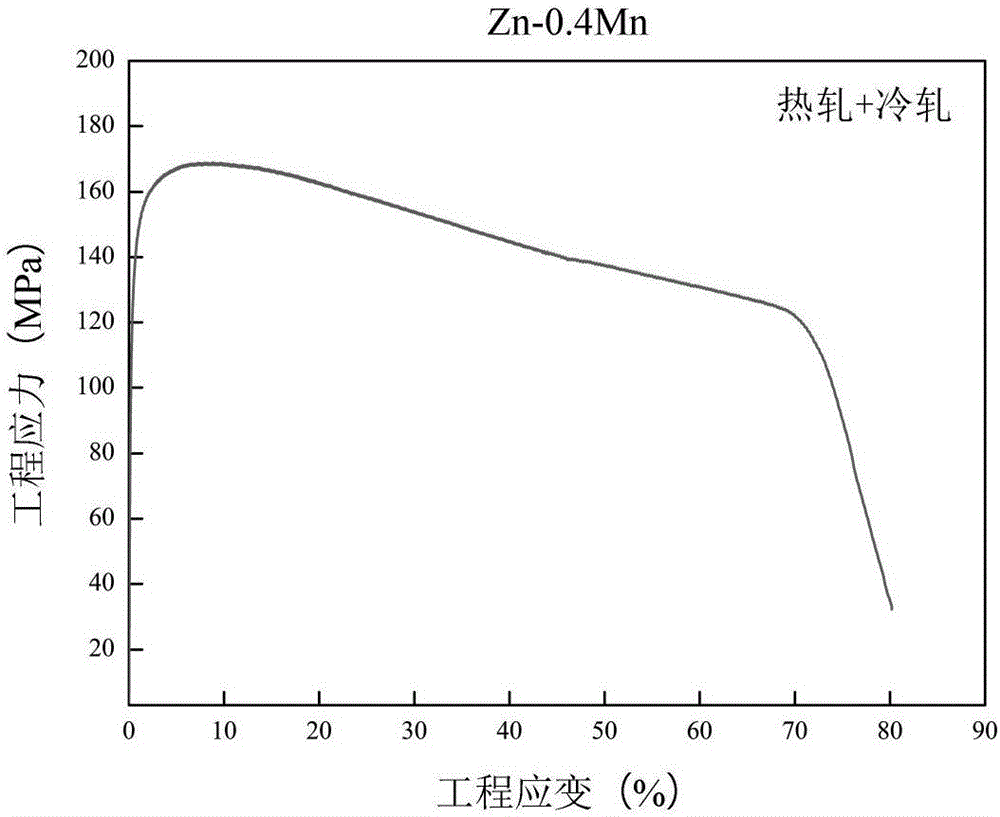

[0047] The cold-rolled Zn-0.4Mn alloy sheet was prepared and the mechanical properties of the material were tested.

[0048] The process flow is: hot-rolled sheet → cold-rolled → finished sheet.

[0049] The hot-rolled Zn-0.4Mn alloy plate is cold-rolled, and its thickness is rolled from 5mm to 1mm through 8 passes of cold-rolling. The deformation of each pass is 10.0%, 11.1%, 12.5%, 14.3%, 16.7%, 20%, 25%, 33.3%, and the total deformation is 80.0%.

[0050] image 3 For the cold-rolled Zn-0.4Mn alloy engineering stress-strain curve, by image 3 The yield strength of the cold-rolled Zn-0.4Mn alloy is 117.0MPa, the tensile strength is 168.0MPa, and the elongation is 75.6%, showing ultrahigh plasticity.

Embodiment 3

[0052] Preparation of Zn-0.4Mn alloy sheets by cyclic composite lamination rolling.

[0053] The technological process is: cold-rolled plate → surface treatment → billet assembly → compound cold rolling → heat treatment → compound hot rolling → surface treatment → billet assembly → ... (multiple cycles) ... → finished plate.

[0054] The surfaces to be compounded of two cold-rolled Zn-0.4Mn alloy plates with a thickness of 1 mm were polished with sandpaper, and then mechanically polished. Stack them up and down to form blanks, and connect them with spot welding at one end. The clad plate with a total thickness of 2 mm after billet assembly is sent to a cold rolling mill for clad rolling, with a deformation of 50%. After cold rolling, the thickness of the clad plate is reduced to 1 mm, and the thickness of a single layer is reduced to 0.5 mm. Heat treatment is carried out on the cold-rolled clad plate, and the process system is 200 ° C for 0.5 hours. Then carry out compound h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com