Zn-HA series zinc alloy, and preparation method and application thereof

A zinc alloy, zn-ha technology, applied in pharmaceutical formulations, dental preparations, molded cups, etc., to achieve the effects of inhibiting the proliferation of smooth muscle cells, excellent antibacterial properties, and inhibiting the growth of osteoclasts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1, preparation Zn-HA series zinc alloy:

[0083] 1) Using pure Zn powder (purity 99.9%, particle size 45-109 μm) (purchased from Alfa Aesar), HA powder (purity 99%, length 150nm) (purchased from Beijing Deke Island Gold Co., Ltd.) as raw materials, according to different Mass ratio (mass ratio of Zn to HA is 99:1, 95:5, 90:10 respectively) in a vacuum glove box, added to a vacuum ball mill tank under the protection of argon, and mixed by a planetary ball mill at a ball milling speed of 250rpm , the ball-to-material ratio is 10:1, and the ball milling time is 40 minutes to obtain a uniform mixture of different Zn and HA mass ratios, which are stored in an argon protective atmosphere to prevent oxidation;

[0084] 2) Put the homogeneous mixture in step 1) into the graphite abrasive tool, pressurize axially and sinter by spark plasma vacuum: the initial sintering pressure is 1MPa, the heat preservation sintering pressure is 60MPa, firstly the temperature is rais...

Embodiment 2

[0085] Embodiment 2, preparation is coated with the Zn-HA series zinc alloy of ceramic coating:

[0086] 1) Using pure Zn powder (purity 99.9%, particle size 45-109 μm) (purchased from Alfa Aesar), HA powder (purity 99%, length 150nm) (purchased from Beijing Deke Island Gold Co., Ltd.) as raw materials, according to different Mass ratio (mass ratio of Zn to HA is 99:1, 95:5, 90:10 respectively) in a vacuum glove box, added to a vacuum ball mill jar under the protection of argon, and mixed by a planetary ball mill at a ball milling speed of 200rpm , the ball-to-material ratio is 20:1, and the ball milling time is 60 minutes to obtain a uniform mixture of different Zn and HA mass ratios, which are stored in an argon protective atmosphere to prevent oxidation;

[0087] 2) Put the homogeneous mixture in step 1) into the graphite abrasive tool, pressurize axially and sinter by spark plasma vacuum: the initial sintering pressure is 1MPa, the heat preservation sintering pressure is 5...

Embodiment 3

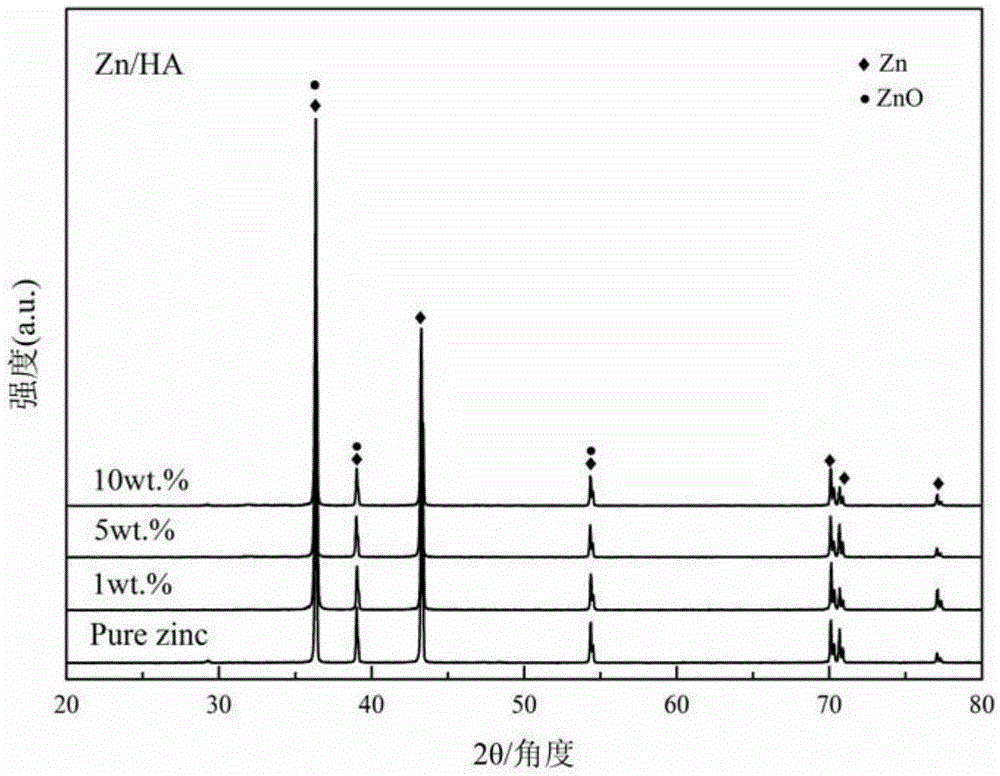

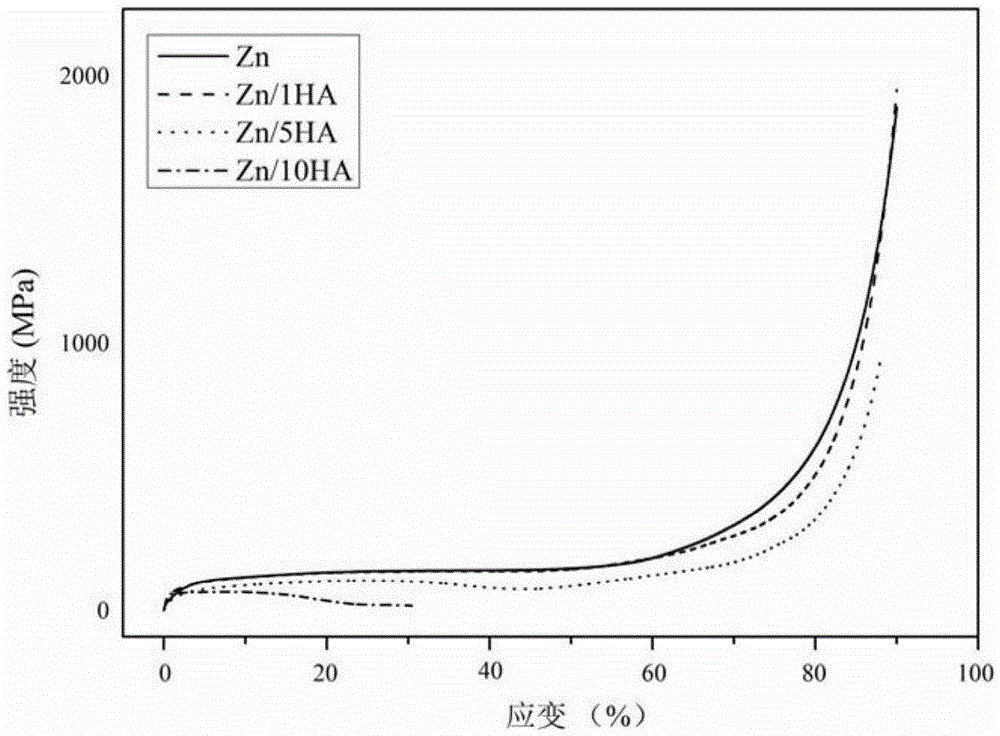

[0090] Embodiment 3, Zn-HA system zinc alloy microstructural analysis

[0091] The Zn-HA series zinc alloy in Example 1 was prepared by wire-cutting a 10×10×1 mm sample, which was sequentially ground and polished by 400#, 800#, 1200# and 2000# SiC sandpaper series. After ultrasonic cleaning in acetone, absolute ethanol and deionized water for 15 min, dry at 25 °C. The sample was subjected to X-ray diffraction analysis, etched with 4% nitric acid alcohol for 5-30 seconds, washed with deionized water, dried, observed under a metallographic microscope, and tested for density by a densitometer.

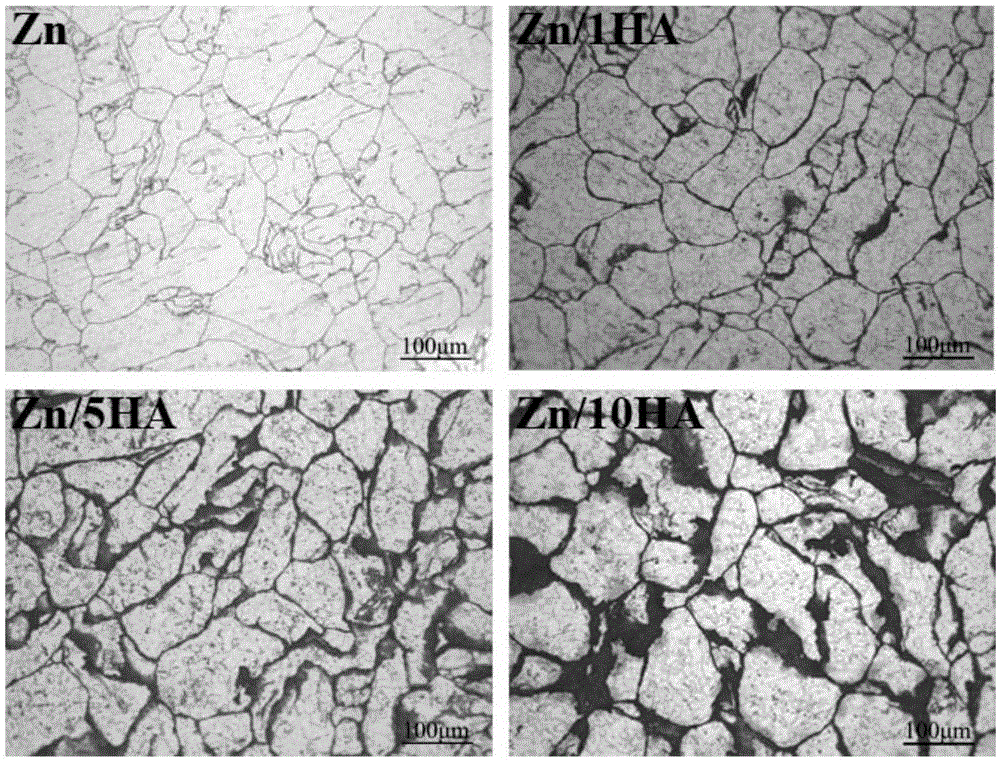

[0092] figure 1 It is Zn-HA series zinc alloy metallographic, from figure 1 It can be seen that HA is evenly distributed on the boundary of pure Zn particles. With the increase of HA content, HA on the boundary begins to gather, which breaks the bond between pure Zn particles. The main physical link between pure Zn particles and HA The binding did not take place chemically.

[0093] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com