Formaldehyde catching agent and preparation method thereof

A formaldehyde scavenger and dispersant technology, applied in the field of formaldehyde scavenger and its preparation, can solve the problems of difficult extraction of tea polyphenols, unsuitable for large-scale production, secondary pollution, etc., and achieves easy large-scale production and complete removal of formaldehyde. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

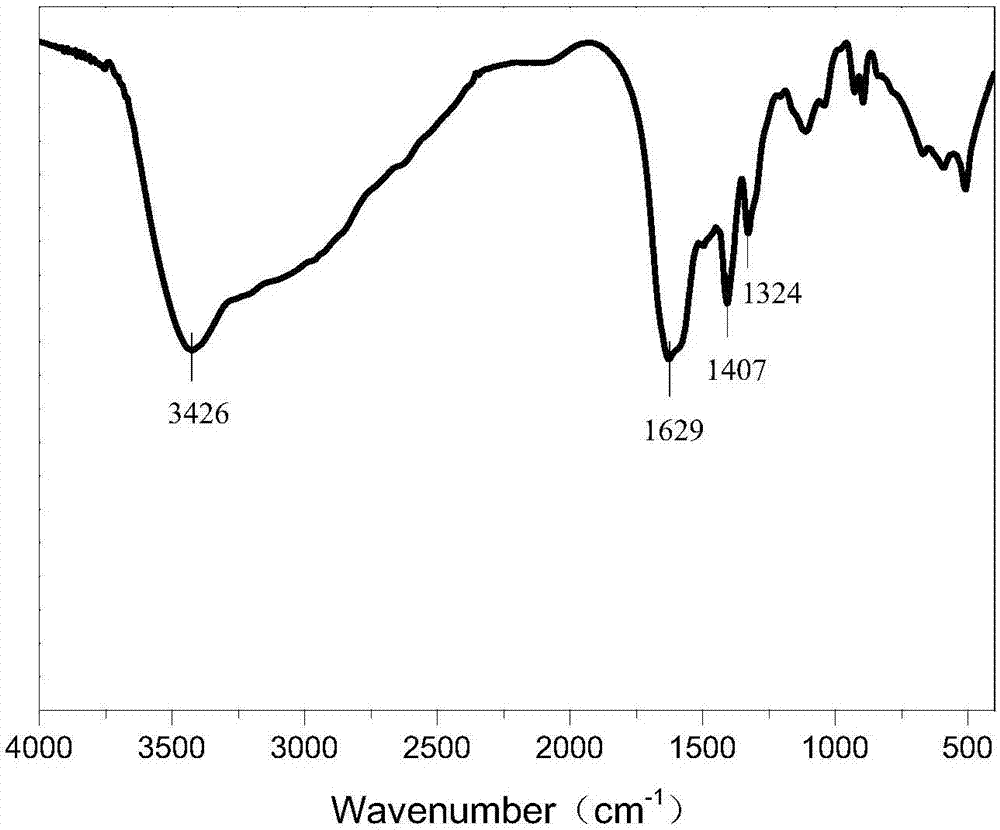

Embodiment 1

[0047] A formaldehyde trapping agent, the ratio of raw materials is as follows by mass: 40 parts of acrylic acid, 30 parts of glycidyl methacrylate, 30 parts of glycine, 30 parts of alanine, 80 parts of hydroxylamine, 15 parts of ethanol, 20 parts of urea, 20 parts Parts of glucose, 3 parts of potassium persulfate, 5 parts of sodium alginate, 10 parts of titanium dioxide, 20 parts of sodium carbonate, 40 parts of sodium citrate, 4500 parts of deionized water.

[0048] The preparation method of above-mentioned formaldehyde trapping agent, comprises the steps:

[0049] ① In parts by mass, add deionized water, glycine, alanine, hydroxylamine, ethanol, urea, and glucose into the stirrer, feed nitrogen into the reactor, and heat to 70°C.

[0050] ②Add the initiator, continue to feed nitrogen into the reactor, and heat to 85°C.

[0051] ③ After 15 minutes, add acrylic acid and glycidyl methacrylate and react for 2 hours.

[0052] ④ Add titanium dioxide, stir for 2 hours, add sodiu...

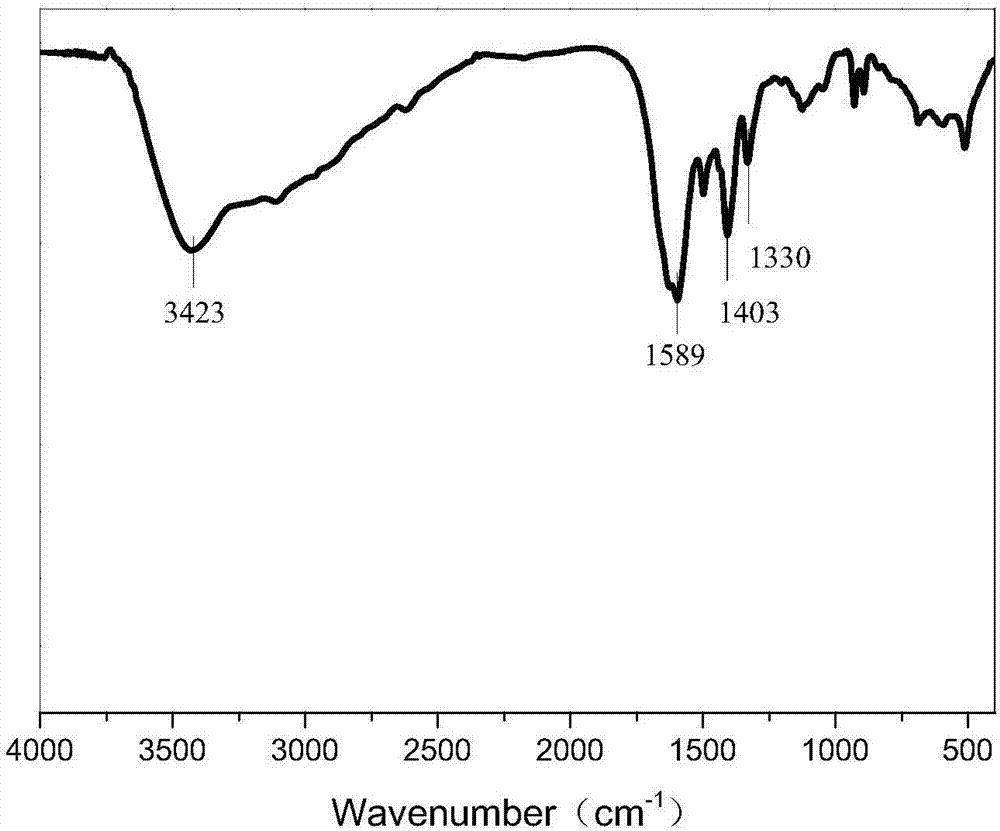

Embodiment 2

[0057] A formaldehyde capture agent, the ratio of raw materials is as follows by mass: 30 parts of acrylic acid, 80 parts of glycidyl methacrylate, 20 parts of glycine, 15 parts of alanine, 15 parts of glutamic acid, 50 parts of hydroxylamine, 20 parts of ethanol , 25 parts of urea, 20 parts of glucose, 10 parts of ammonium persulfate, 35 parts of PEI (molecular weight of 1300), 35 parts of chitosan, 10 parts of titanium dioxide, 20 parts of sodium carbonate, 30 parts of sodium citrate, 3500 parts of deionized water .

[0058] The preparation method of above-mentioned formaldehyde trapping agent, comprises the steps:

[0059] ① In parts by mass, add deionized water, glycine, alanine, glutamic acid, hydroxylamine, ethanol, urea, and glucose into the stirrer, feed nitrogen into the reactor, and heat to 60°C.

[0060] ②Add the initiator, continue to feed nitrogen into the reactor, and heat to 90°C.

[0061] ③After 20 minutes, add acrylic acid and glycidyl methacrylate and react...

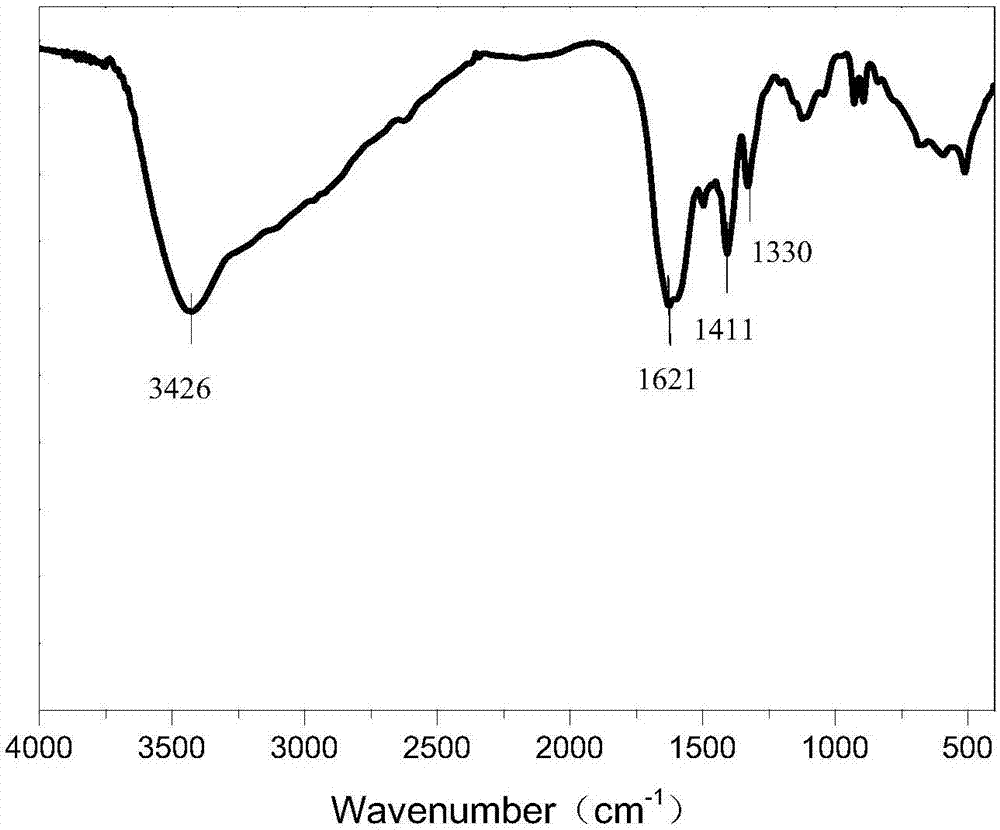

Embodiment 3

[0067] A kind of formaldehyde trapping agent, raw material ratio is as follows by mass: 60 parts of acrylic acid, 40 parts of glycidyl methacrylate, 30 parts of glycine, 30 parts of glutamic acid, 80 parts of hydroxylamine, 25 parts of ethanol, 30 parts of urea, 25 parts Parts of glucose, 2 parts of ammonium persulfate, 1 part of silicon dioxide, 30 parts of sodium carbonate, 30 parts of PEI (molecular weight 1300), 40 parts of sodium citrate, 5000 parts of deionized water.

[0068] The preparation method of above-mentioned formaldehyde trapping agent, comprises the steps:

[0069] ① In parts by mass, add deionized water, glycine, glutamic acid, hydroxylamine, ethanol, urea, and glucose into the stirrer, feed nitrogen into the reactor, and heat to 80°C.

[0070] ②Add the initiator, continue to feed nitrogen into the reactor, and heat to 90°C.

[0071] ③After 10 minutes, add acrylic acid and glycidyl methacrylate and react for 10 hours.

[0072] ④ Add silicon dioxide, stir fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com