Nickel-cobalt-iron ternary metal oxide nano tubular composite material and preparation method thereof

A ternary metal and composite material technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of small actual capacitance, poor conductivity, small specific surface area, etc. Simple operation and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

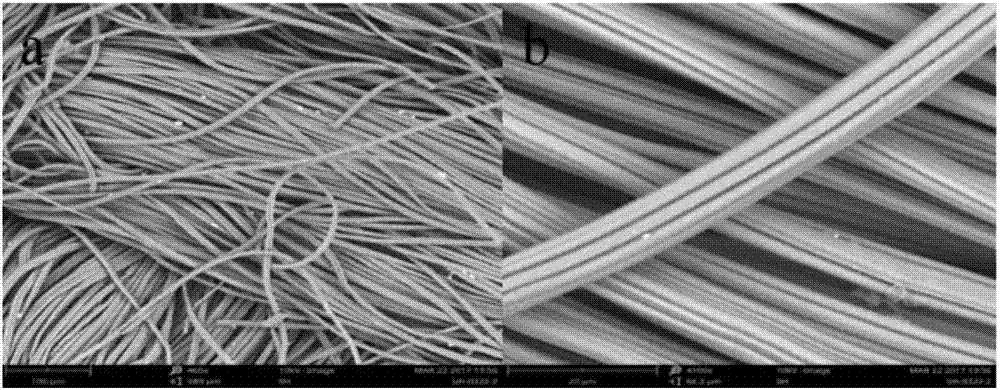

[0034] (1) Carbon fiber cloth pretreatment: Sonicate 30×30×0.1 mm carbon fiber cloth in absolute ethanol and distilled water for 15 min, wash, dry and weigh.

[0035] (2) Hydrothermal growth of NiCo 2 o 4 Precursor: Take 50 ml of distilled water, 1.1897 g of cobalt chloride hexahydrate, 0.5942 g of nickel chloride hexahydrate, 0.7289 g of CTAB, and 0.5405 g of urea, put them into a 200 ml beaker, mix well and mix with the treated The carbon fiber cloth was added into a polytetrafluoroethylene-lined hydrothermal kettle for hydrothermal reaction at 100 °C for 12 h. After the reaction was over, the samples were taken out, cleaned with deionized water, dried and weighed.

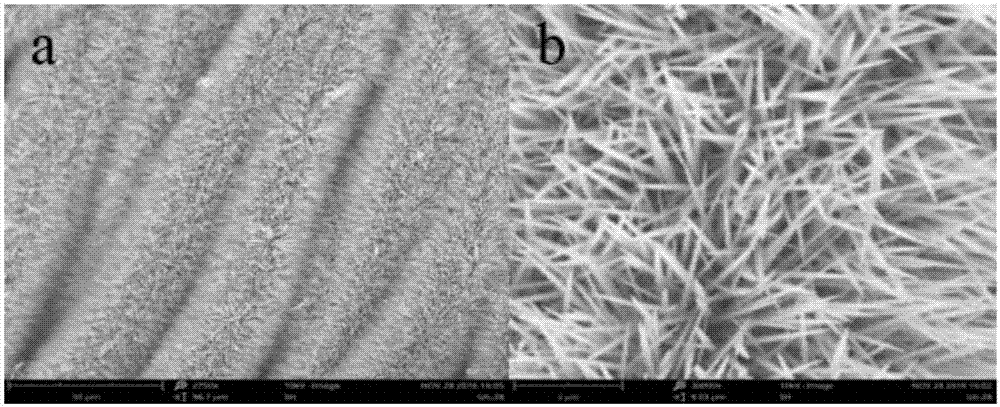

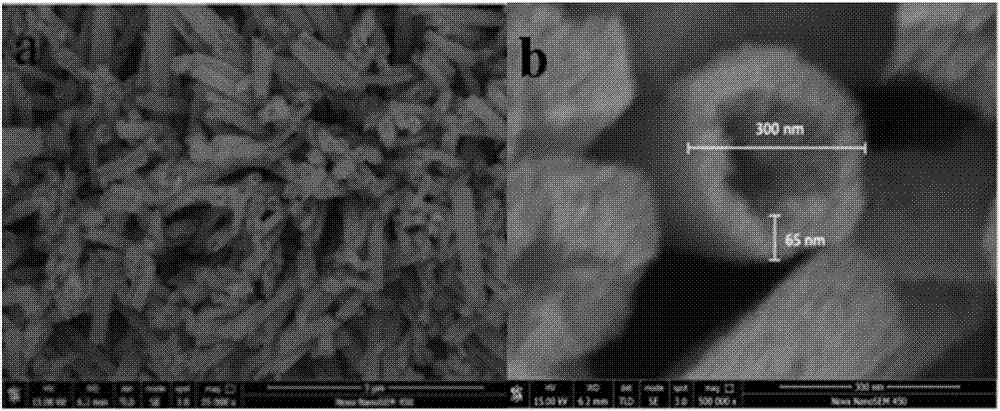

[0036] (3) Preparation of NiCo by water bath method 2-x Fe x o 4 Nanotube-shaped composite material: Take 50 ml of distilled water and the materials prepared in step (2) into a 200 ml beaker, and heat in a water bath. Take ferric chloride hexahydrate (the molar concentration in terms of iron is 0.1mol / L) a...

Embodiment 2

[0039](1) Carbon fiber cloth pretreatment: Sonicate 30×30×0.1 mm carbon fiber cloth in absolute ethanol and distilled water for 15 min, wash, dry and weigh.

[0040] (2) Hydrothermal growth of NiCo 2 o 4 Precursor: Take 50 ml of distilled water, 1.1897 g of cobalt chloride hexahydrate, 0.5942 g of nickel chloride hexahydrate, 0.7289 g of CTAB, and 0.5405 g of urea, and add them to a 200 ml beaker. The carbon fiber cloth was put into a polytetrafluoroethylene-lined hydrothermal kettle for hydrothermal reaction, and the reaction was carried out at 100 °C for 24 h. After the reaction was over, the samples were taken out, cleaned with deionized water, dried and weighed.

[0041] (3) Preparation of NiCo by water bath method 2-x Fe x o 4 Nanotube-shaped composite material: Take 50 ml of distilled water and the materials prepared in step (2) into a 200 ml beaker, and heat in a water bath. Take ferric chloride hexahydrate (the molar concentration in terms of iron is 0.2mol / L) an...

Embodiment 3

[0044] (1) Carbon fiber cloth pretreatment: Sonicate 30×30×0.1 mm carbon fiber cloth in absolute ethanol and distilled water for 15 min, wash, dry and weigh.

[0045] (2) Hydrothermal growth of NiCo 2 o 4 Precursor: Take 50 ml of distilled water, 1.1897 g of cobalt chloride hexahydrate, 0.5942 g of nickel chloride hexahydrate, 0.7289 g of CTAB, and 0.5405 g of urea, and add them to a 200 ml beaker. The carbon fiber cloth was put into a polytetrafluoroethylene-lined hydrothermal kettle for hydrothermal reaction, and the reaction was carried out at 120 °C for 24 h. After the reaction was over, the samples were taken out, cleaned with deionized water, dried and weighed.

[0046] (3) Preparation of NiCo by water bath method 2-x Fe x o 4 Nanotube-shaped composite material: Take 50 ml of distilled water and the materials prepared in step (2) into a 200 ml beaker, and heat in a water bath. Take ferric chloride hexahydrate (the molar concentration in terms of iron is 1 mol / L) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com