Method for synthesizing CsSnX3 perovskite quantum dots by microwave-assisted heating

A microwave-assisted, quantum dot technology, applied in the field of semiconductor and nanotechnology, can solve the problems of uneven heat transmission speed and distribution, temperature display accuracy error, low fluorescence yield of quantum dots, etc., to achieve short preparation cycle, heating and cooling The effect of high speed and high fluorescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

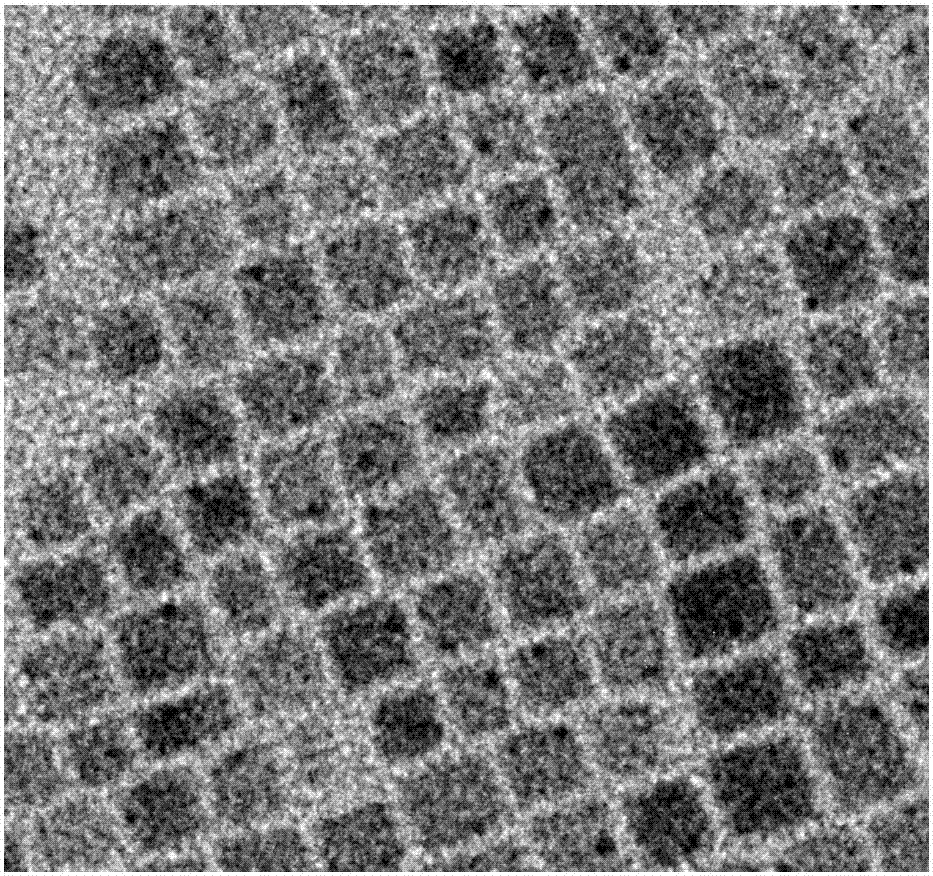

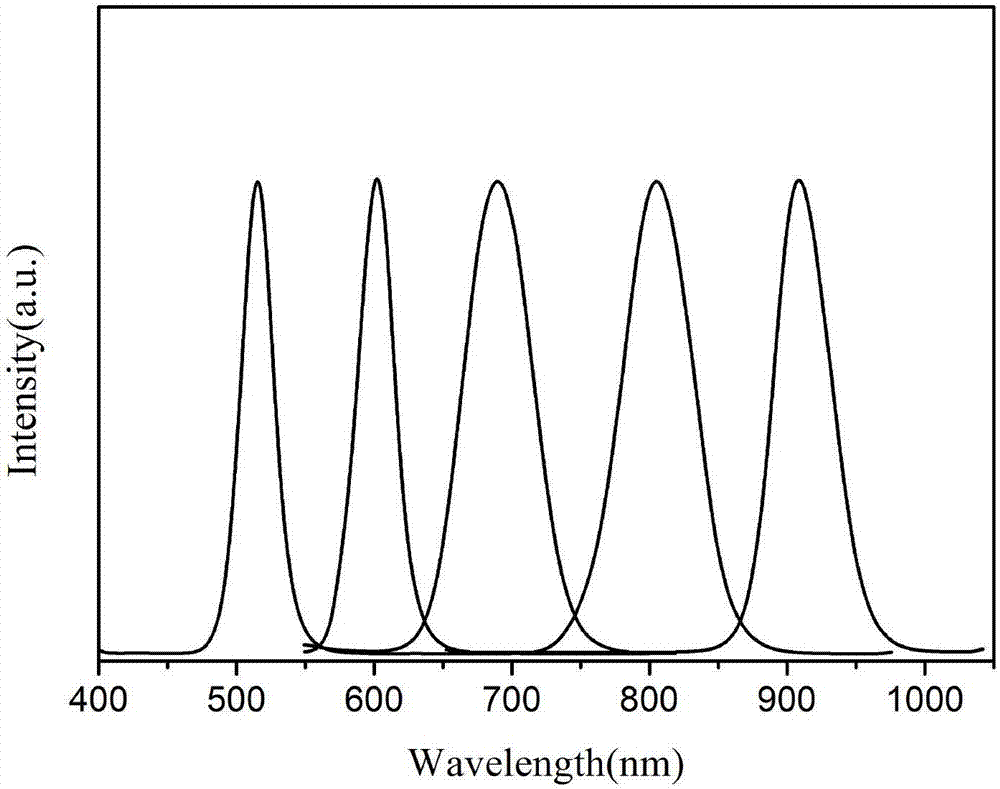

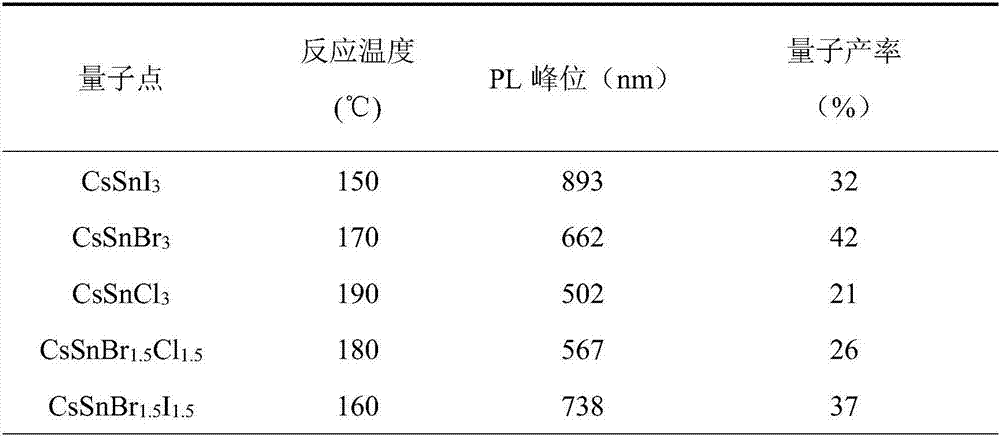

Image

Examples

Embodiment 1

[0022] In an inert atmosphere, the tin halide (SnX 2 ) Was placed in trioctyl phosphine (TOP), stirred, vacuumed at the same time and heated to 100 ℃, kept until SnX2 was completely dissolved to obtain a precursor solution with a molar concentration of 0.5M tin; the cesium carbonate (Cs 2 CO 3 ), oleic acid (OA) and oleylamine (OAm) in a molar ratio of 1:0.375:0.375, added to the mixed solvent of octadecene (ODE) and glycerol with a volume ratio of 1:3, and then placed in microwave heating In the device, stir, evacuate, heat up to 60°C, keep it warm until it is dissolved, and obtain a precursor solution with a molar concentration of 0.5M cesium; then pass inert gas into the cesium precursor solution, stop vacuuming, and continue to raise When the temperature reaches 150~190℃, quickly inject tin precursor solution, stop microwave heating after 1 min of reaction, and place in an ice water bath to quickly cool down; add methyl acetate or tert-butanol, centrifuge, and then wash with ...

Embodiment 2

[0026] In an inert atmosphere, the tin halide (SnX 2 ) Is placed in trioctyl phosphine (TOP), stirring, while vacuuming and heating to 150 ℃, heat preservation to SnX 2 Dissolve completely to obtain a precursor solution with a molar concentration of 1.5M tin; add cesium carbonate (Cs 2 CO 3 ), oleic acid (OA) and oleylamine (OAm) are added to the mixed solvent of octadecene (ODE) and silicon balls with a volume ratio of 1:5 in a molar ratio of 1:0.375:0.375, and then placed in the microwave In the heating device, stir, evacuate, and raise the temperature to 100°C, keep it warm until it is dissolved, and obtain a precursor solution with a molar concentration of 1.5M cesium; then pass inert gas into the cesium precursor solution, stop vacuuming, and continue Raise the temperature to 150~190℃, quickly inject tin precursor solution, stop microwave heating after 5 minutes of reaction, and place in an ice water bath to quickly cool down; add methyl acetate or tert-butanol, centrifuge, ...

Embodiment 3

[0030] In an inert atmosphere, the tin halide (SnX 2 ) Is placed in trioctyl phosphine (TOP), stirring, while vacuuming and heating to 120 ℃, heat preservation to SnX 2 Dissolve completely to obtain a precursor solution with a molar concentration of 0.8M tin; add cesium carbonate (Cs 2 CO 3 ), oleic acid (OA) and oleylamine (OAm) are added to the mixture of octadecene (ODE) and polar solvent (glycerol silica ball mixture) at a molar ratio of 1:0.375:0.375 with a volume ratio of 1:4 In the solvent, it is then placed in a microwave heating device, stirred, vacuumed, and heated to 90°C, kept until dissolved, to obtain a precursor solution with a molar concentration of 0.8M cesium; then pass inert gas into the cesium precursor solution, And stop vacuuming, and then continue to raise the temperature to 150~190℃, quickly inject tin precursor solution, stop microwave heating after 2 minutes of reaction, and place in an ice water bath to quickly cool down; add methyl acetate or tert-buta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com