Ti (titanium)-doped gallium oxide crystal, as well as preparation method and application thereof

A technology of gallium oxide and crystal, applied in the field of titanium-doped gallium oxide crystal and its preparation, new laser crystal and its preparation, to achieve the effects of small lattice distortion, high-energy laser output, and uniform doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

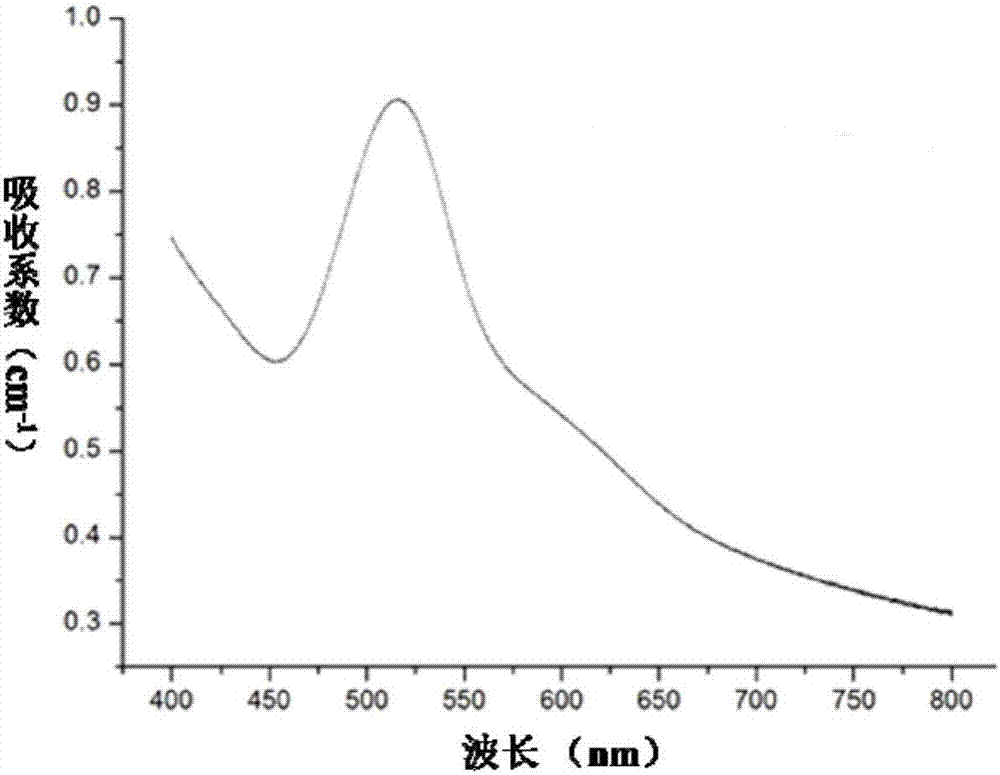

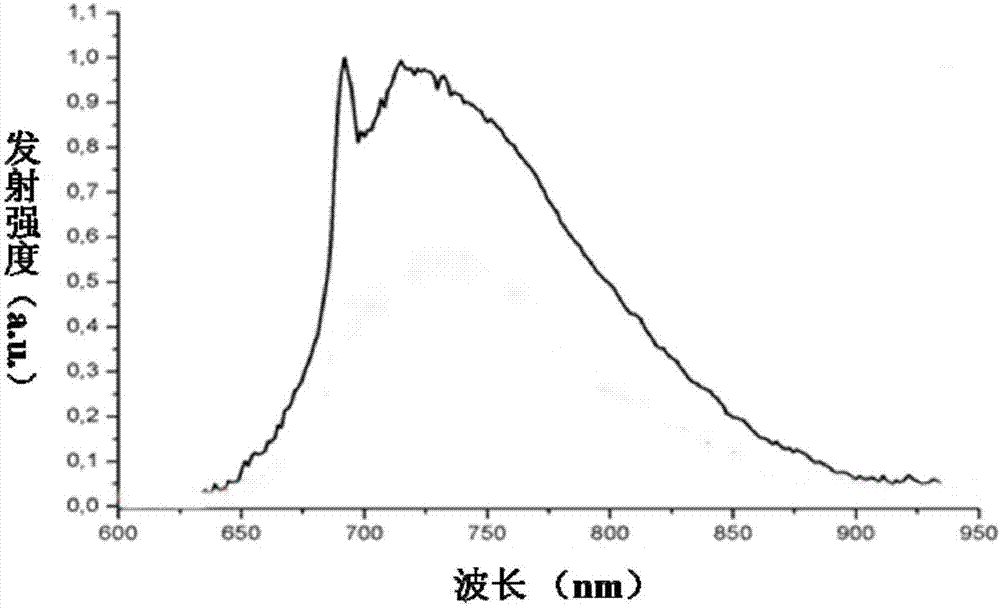

[0036] Example 1: x=0.005, the chemical formula of titanium-doped gallium oxide crystal is β-(Ga 0.995 Ti 0.005 ) 2o 3

[0037] The preparation method of titanium-doped gallium oxide crystal is as follows:

[0038] (1) Selection and processing of raw materials

[0039] Weigh Ga with a purity of 99.999% according to the stoichiometric ratio 2 o 3 、Ti 2 o 3 , Put the raw materials into the mixer and mix them thoroughly for 48 hours. After the mixing is completed, the mixed raw materials are vacuum-dried at 100-200° C. for 5 hours to prevent absorbed water from entering the growth system, and the dried raw materials are pressed into a cake shape with a hydraulic press. Then put the cake into a corundum crucible and sinter at 1350° C. for 48 hours to obtain a titanium-doped gallium oxide polycrystalline material.

[0040] (2) Crystal growth

[0041] a. Put the pressed raw materials into the iridium crucible, and place the cuboid iridium mold. The upper surface of the ir...

Embodiment 2

[0049] Example 2: x=0.02, the chemical formula of titanium-doped gallium oxide crystal is β-(Ga 0.98 Ti 0.02 ) 2 o 3

[0050] The preparation method of titanium-doped gallium oxide crystal is as follows:

[0051] (1) Selection and processing of raw materials

[0052] Weigh Ga with a purity of 99.999% according to the stoichiometric ratio 2 o 3 、Ti 2 o 3 , Put the raw materials into the mixer and mix them thoroughly for 48 hours. After the mixing is completed, the mixed raw materials are vacuum-dried at 100-200° C. for 2 hours to prevent absorbed water from entering the growth system, and the dried raw materials are pressed into a cake shape with a hydraulic press. Then the cake was put into a corundum crucible and sintered at 1400° C. for 48 hours to obtain a titanium-doped gallium oxide polycrystalline material.

[0053] (2) Crystal growth

[0054] The difference from the step (2) in Example 1 is that the pulling speed of the crystal will be 5 mm / h; after the cryst...

Embodiment 3

[0055] Example 3: x=0.02, the chemical formula of titanium-doped gallium oxide crystal is β-(Ga 0.98 Ti 0.02 ) 2 o 3

[0056] The preparation method of titanium-doped gallium oxide crystal is as follows:

[0057] (1) Selection and processing of raw materials

[0058] Weigh Ga with a purity of 99.999% according to the stoichiometric ratio 2 o 3 、Ti 2 o 3 , Put the raw materials into the mixer and mix them thoroughly for 48 hours. After the mixing is completed, the mixed raw materials are vacuum-dried at 100-200° C. for 3 hours to prevent absorbed water from entering the growth system, and the dried raw materials are pressed into a cake shape with a hydraulic press. Then the cake was put into a corundum crucible and sintered at 1400° C. for 48 hours to obtain a titanium-doped gallium oxide polycrystalline material.

[0059] (2) Crystal growth

[0060] a. Put the pressed raw materials into the iridium crucible, and place a cylindrical iridium mold. The through hole wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com