A kind of polymer with surface active function and its preparation method and application

A technology of surface activity and polymer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem that oil displacement polymers cannot meet the requirements of medium and low permeability reservoir development, and achieve enhanced resistance to divalent metals Ionic ability, good viscosity-increasing effect, effect of improving surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

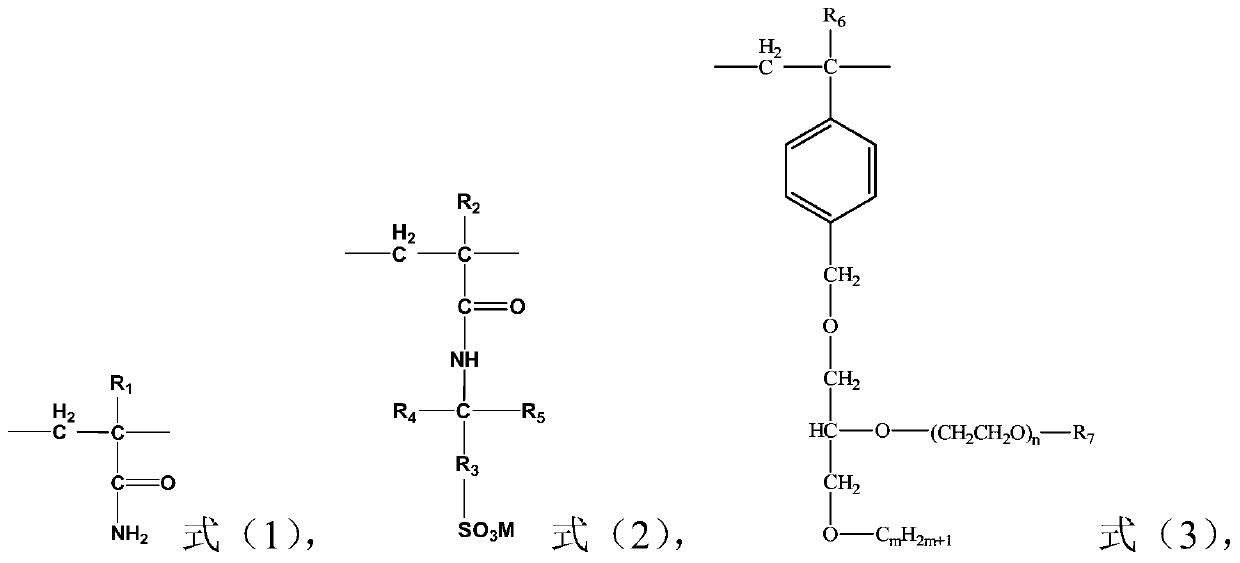

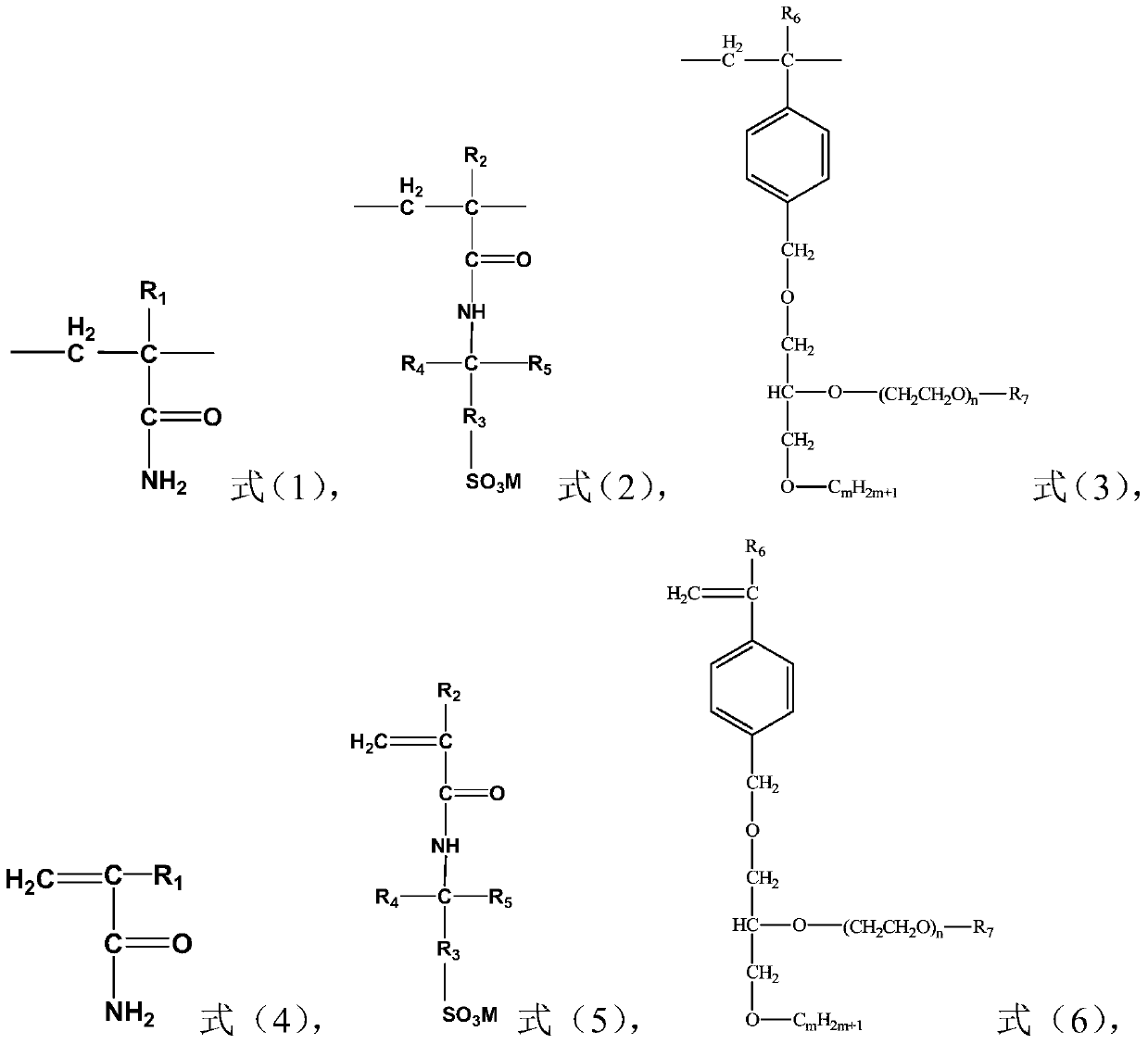

[0037] second aspect , the invention provides a kind of preparation method of the polymer with surface active function, this method comprises: in the presence of initiator and the water as solvent, make monomer D, monomer E and monomer F carry out solution polymerization reaction , wherein, the monomer D is a monomer having a structure shown in formula (4), the monomer E is a monomer having a structure shown in formula (5), and the monomer F is a monomer having a structure shown in formula (6) The monomer of the shown structure, wherein, the consumption of described monomer D, monomer E and monomer F makes the content of structural unit A in the prepared polymer be 55-89.9% by weight, the content of structural unit B is 10 -40% by weight, the content of structural unit C is 0.1-5% by weight, and the viscosity-average molecular weight of the prepared polymer is 22 million-32 million; the structural unit A has the structure shown in formula (1) Structural unit, said structural...

specific Embodiment approach

[0059] According to a preferred embodiment, the preparation method of the polymer with surface active function comprises the following steps:

[0060] Step 1: adding monomer D, monomer E and monomer F into a polymerization reaction bottle to prepare an aqueous solution, and adjusting the pH value of the aqueous solution to 6-10 with alkali;

[0061] Step 2: Add chelating agent, urea aqueous solution, tetramethylethylenediamine and defoamer to the aqueous solution of step 1, and stir evenly;

[0062] Step 3: After bubbling nitrogen gas for 5-60 minutes at a temperature of 0-30°C, add an initiator to the aqueous solution in step 2, and after bubbling nitrogen gas to make it evenly mixed, seal polymerization for 2-15 hours to obtain a polymer colloid;

[0063] Step 4: Take out the colloid, add granular alkali after granulation, make it evenly mixed, and then hydrolyze at 80-90°C for 2-3 hours;

[0064] Step 5: Take out the colloidal particles and then granulate, dry, pulverize ...

Embodiment 1

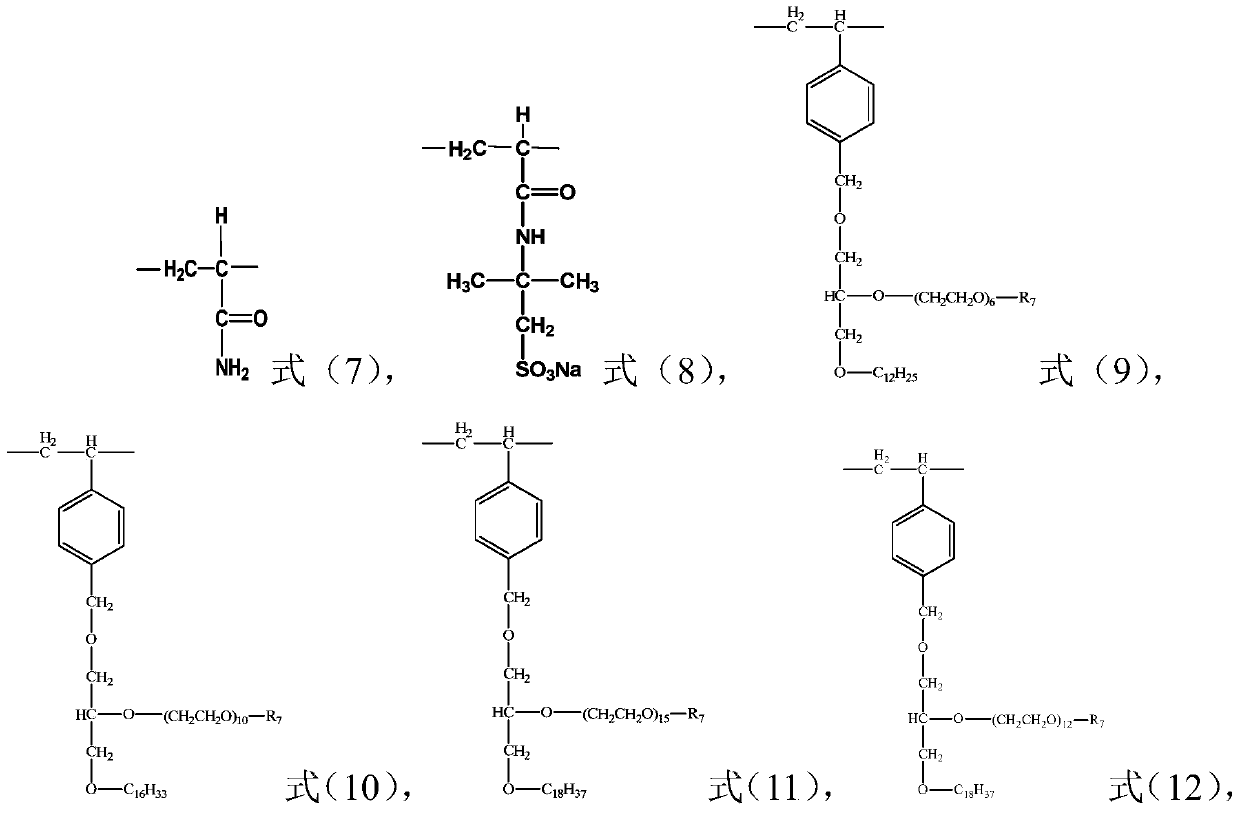

[0076] 1. 15.8g acrylamide (accounting for 79% by weight of the total amount of monomers), 4.0g of 2-acrylamido-2-methylpropanesulfonic acid (accounting for 20% by weight of the total amount of monomers) and 0.2g formula The functional monomer (m=12, n=6, R shown in (15) 7 for SO 3 H, accounting for 1% by weight of the total amount of monomers) was added to the heat-insulating polymerization reaction bottle (ie, the polymerization bottle), and 60.0 g of deionized water was added to dissolve to form an aqueous solution, and then sodium hydroxide was added to adjust the pH value to 6.0;

[0077] 2. Add 1.0 g of 1% by weight EDTA-2Na aqueous solution, 0.5 g of 1% by weight urea aqueous solution, 10.0 mg of tetramethylethylenediamine, and 15.0 mg of dimethyl polysiloxane (defoamer), and stir well ;

[0078] 3. Control the temperature of the aqueous solution at 10°C. After 30 minutes of blowing nitrogen to drive oxygen, add 2.0 g of 0.1 wt % potassium persulfate aqueous solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com