Application of photothermal-conversion cupric sulfidecomposite film in water treatment

A technology of photothermal conversion and composite film, applied in the field of water treatment, can solve the problems of high energy loss and equipment maintenance costs, and achieve the effect of effective utilization of energy, improved efficiency and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, the light-to-heat conversion copper sulfide composite film was prepared according to the following method and its light-to-heat conversion efficiency was verified:

[0034] a. Pretreatment of porous polyethylene film

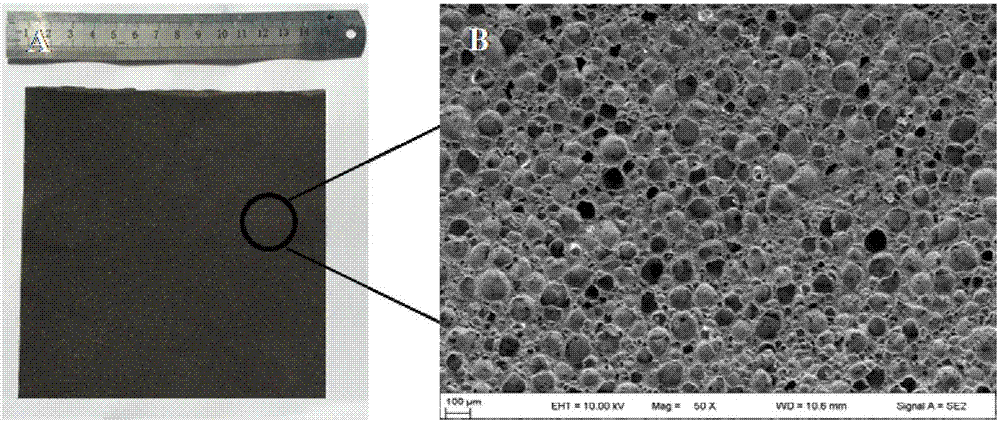

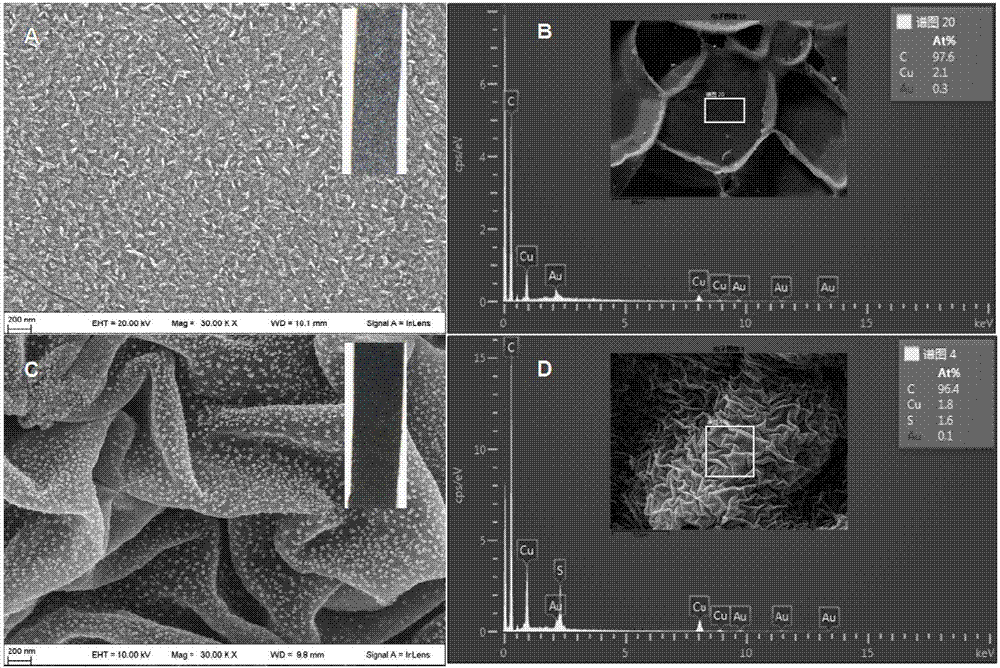

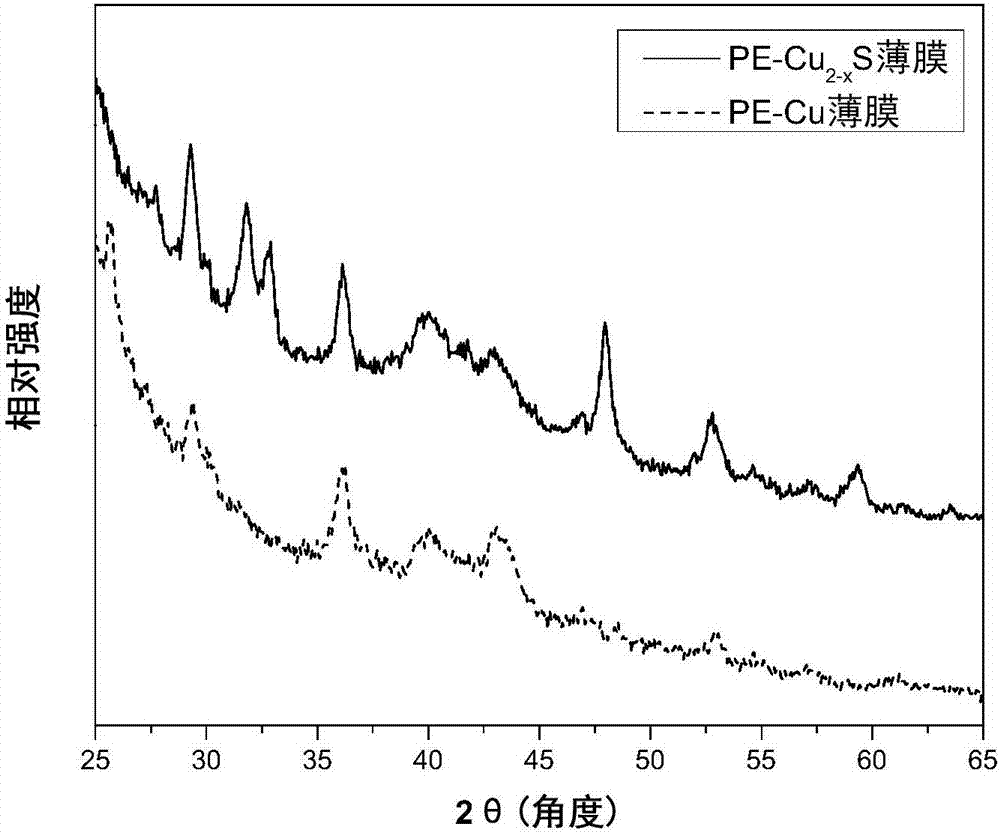

[0035] First, a layer of copper element is sprayed on the surface of a black spongy porous polyethylene film with a thickness of about 153 microns by magnetron sputtering to obtain a PE-Cu film; the quality of the sprayed copper element accounts for 1.46% of the mass of the porous polyethylene film .

[0036] Then put the PE-Cu film into hot water at 50°C for cleaning, take it out, wash it with absolute ethanol and ultrapure water several times in turn, and dry it at 30°C for 12 hours for later use.

[0037] b. Transformation of simple copper on PE-Cu film

[0038] Weigh 0.0369g of thiourea (Tu) and 0.4781g of polyvinylpyrrolidone (PVP), add them into 35mL of ethylene glycol and ultrasonically dissolve them for 20min, then transfer them...

Embodiment 2

[0048] Present embodiment adopts the PE-Cu that embodiment 1 makes 2-x The S film was used for water treatment simulation experiments, as follows:

[0049] a. Take a piece of circular PE-Cu with a diameter of 4 cm 2-x The S film was washed several times with absolute ethanol and ultrapure water, and dried at 30°C for 12 hours for later use.

[0050] b. Fill a cylindrical beaker with a diameter of 4 cm with ultrapure water and place it on an electronic balance. Place the device under the illumination of a halogen lamp with an energy of 275W. The surface of the ultrapure water is 17 cm away from the halogen lamp, and the light source is irradiated vertically on the surface of the water body. The irradiation time was 14 minutes, and the mass change of the device due to the evaporation of ultrapure water during the irradiation process was recorded at the same time.

[0051] c. Fill a cylindrical beaker with a diameter of 4 cm with ultrapure water, place it on an electronic bala...

Embodiment 3

[0054] In this embodiment, the light source in Embodiment 2 is changed to a power density of about 1000W m -2 The same water treatment simulation experiment was carried out with simulated sunlight, and the irradiation time was 30 minutes.

[0055] The results showed that after 30 minutes of irradiation, the uncovered PE-Cu 2-x The pure water mass of the S film decreased by 0.23g, and the evaporation rate was 0.366kg m -2 h -1 . And the surface is covered with PE-Cu 2-x After the pure water of the S film is irradiated under simulated sunlight for 30 minutes, the mass of pure water decreases by 0.52g, and the evaporation rate is 0.828kg m -2 h -1 , indicating PE-Cu 2-x The S film can produce a photothermal effect under simulated sunlight irradiation, which can increase the temperature of the water surface and improve the efficiency of evaporating water.

[0056] The conversion efficiency of the heat required for water evaporation by solar energy is calculated by formula η...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com