Method for producing gamma-polyglutamic acid organic fertilizer by utilizing sludge

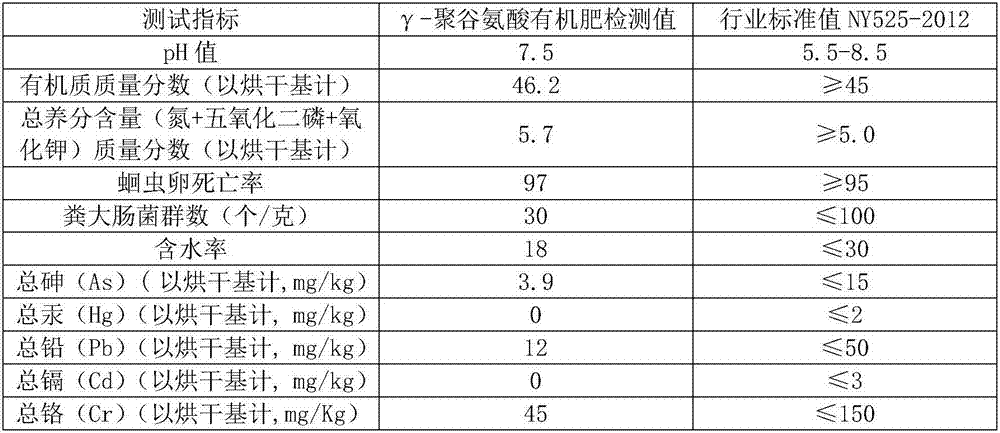

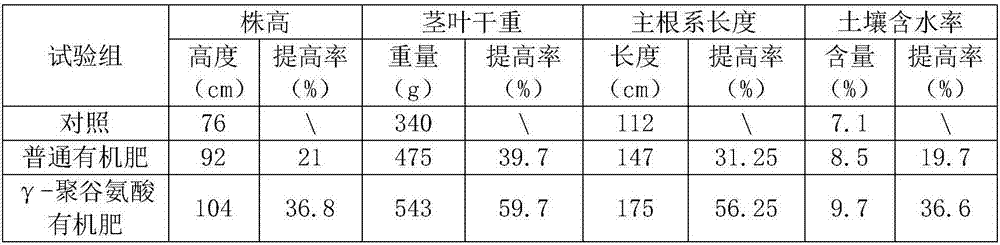

A technology for polyglutamic acid and organic fertilizer, which is applied in the field of producing γ-polyglutamic acid organic fertilizer, can solve the problems of difficulty in popularization and application, high price, and high production cost of γ-polyglutamic acid organic fertilizer, and can reduce production Cost, low production cost, effect of reducing water and nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1), the raw materials are put into the mixer according to the following mass percentages: 64% of heavy metal-removed dewatered sludge, 20% of straw, 10% of pig manure, and 5% of medical stone, so that the carbon-nitrogen molar ratio in the matrix is 20: 1~25:1, wherein the moisture content of the heavy metal dewatered sludge is 75~80%.

[0042] 2) Dilute and activate the 0.5% biological fermentation agent in an appropriate amount of water.

[0043] 3) Sprinkle the activated bio-fermentation agent on the mixed material obtained in step 1), spray tap water therein to adjust the moisture content to 50-65%, mix again and move it to the tank fermentation bed for composting Ripe. Keep feeding air into the trough-type pipeline every day. After 2 days of composting, the temperature of the compost body reaches above 40°C. At this time, the compost body is turned over every 2 days. After 25 days, the organic fertilizer is fully decomposed to obtain bio-organic fertilizer.

[...

Embodiment 2

[0047] 1), the raw materials are put into the mixer according to the following mass percentages: 55% of heavy metal-removed dewatered sludge, 30% of straw, 10% of pig manure, and 4% of medical stone, so that the carbon-nitrogen molar ratio in the matrix is 20: 1~25:1.

[0048] 2) Dilute and activate the biological fermentation agent with a mass percentage of 1% in an appropriate amount of water.

[0049] 3) Sprinkle the activated bio-fermentation agent on the mixed material obtained in step 1), spray tap water therein to adjust the moisture content to 50-65%, mix again and move it to the tank fermentation bed for composting Ripe. Keep feeding air into the trough pipeline every day. After 2 days of composting, the temperature of the compost body reaches above 40°C. At this time, the compost body is turned over every 2 days. After 28 days, the organic fertilizer is fully decomposed to obtain bio-organic fertilizer.

[0050] 4) Add 9% monosodium glutamate meal (with a glutami...

Embodiment 3

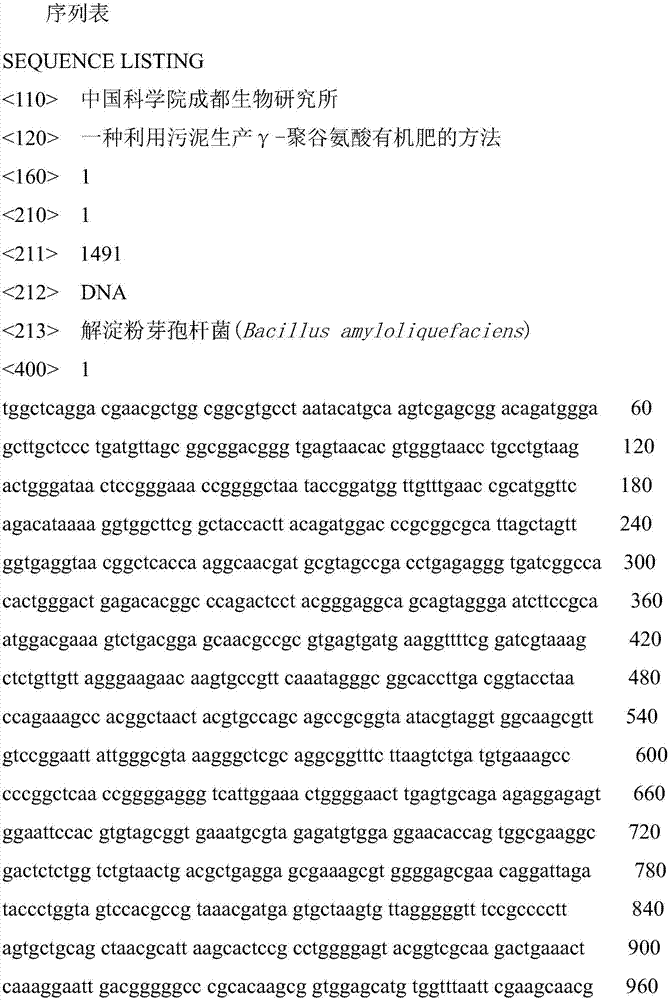

[0053] Preparation of biological leavening agent:

[0054] 1), preparation medium:

[0055] a. Beef extract peptone solid slant medium: the formula is 3g beef extract, 10g peptone, 5g NaCl, 20g agar, add water to 1000mL, pH 7.0-7.4;

[0056] b. Beef extract-peptone liquid medium: its formula is 3g of beef extract, 10g of peptone, 5g of NaCl, supplemented with water to 1000mL, pH 7.0-7.4.

[0057] 2), activation, cultivation:

[0058] Sterilize the beef extract peptone solid slant medium at 121°C for 30 minutes, then insert Bacillus amyloliquefaciens JX-6 into the solid slant medium, and activate it at 30-37°C for 36 hours; sterilize the beef extract peptone liquid medium After being sterilized at 121°C for 30 minutes, the activated Bacillus amyloliquefaciens JX-6 was inserted into the liquid medium, shaken and cultivated at 35°C and 150 r / min for 24 hours to prepare a biological fermentation agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com