Preparation method of attapulgite mycotoxin adsorbent with antibacterial function

A mycotoxin adsorption, attapulgite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of unsatisfactory removal of zearalenone, lack of alternative antibiotics, and large surfactant dosage. To overcome the problem of feed safety, enhance the affinity and the interaction force between chemical functional groups, and the process is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

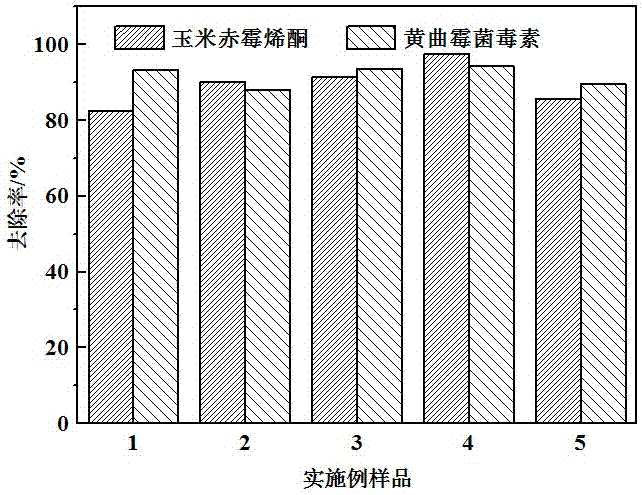

Embodiment 1

[0028] Embodiment 1: take 100g attapulgite clay and be mixed with the ore slurry of mass concentration 10%, then add the sulfuric acid of attapulgite quality 3% and attapulgite quality 5% organic acid salt composite modifier (wherein potassium diformate and The mass ratio of potassium sorbate is 8:2), stirred at room temperature for 2 hours, continued to add cetyl dimethyl betaine with 5% mass of attapulgite clay, gradually raised the temperature to 45±5°C, reacted for 2 hours, centrifuged, washed , drying and pulverizing to obtain an attapulgite mycotoxin adsorbent with antibacterial function.

Embodiment 2

[0029] Embodiment 2: take 100g attapulgite clay and be mixed with the ore slurry of mass concentration 10%, then add the sulfuric acid of attapulgite quality 5% and attapulgite quality 10% organic acid salt composite modifier (wherein potassium diformate and The mass ratio of potassium sorbate is 6:4), stirred at room temperature for 4 hours, passed through a 200-mesh sieve to remove quartz impurities, then added tetradecyl dimethyl betaine with 10% of the mass of attapulgite clay, and gradually raised the temperature to 60±5°C , after reacting for 3 hours, centrifuge, wash, dry and pulverize to obtain the attapulgite mycotoxin adsorbent with antibacterial function.

Embodiment 3

[0030] Embodiment 3: Take 100g of attapulgite clay and prepare it into a slurry with a mass concentration of 15%, then add sulfuric acid with 7% of attapulgite mass and organic acid salt compound modifier with 10% attapulgite mass (wherein: two The mass ratio of potassium formate to potassium sorbate is 5:5), stirred at room temperature for 4 hours, passed through a 200-mesh sieve to remove quartz impurities, then added cocamidopropyl betaine with 5% mass of attapulgite hydroclay, and gradually heated to 80± After reacting at 5°C for 4 hours, centrifuge, wash, dry, and pulverize to obtain an attapulgite mycotoxin adsorbent with antibacterial function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com