Red mud doped manganese and cerium catalyst used for flue gas denitrification, and preparation method thereof

A catalyst and red mud technology, which is applied in the field of red mud doped manganese cerium catalyst and its preparation, can solve the problems of large specific surface area, impact on health, low thermal stability, etc., and achieve high NO conversion rate and N2 selectivity, Excellent denitrification catalytic activity and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

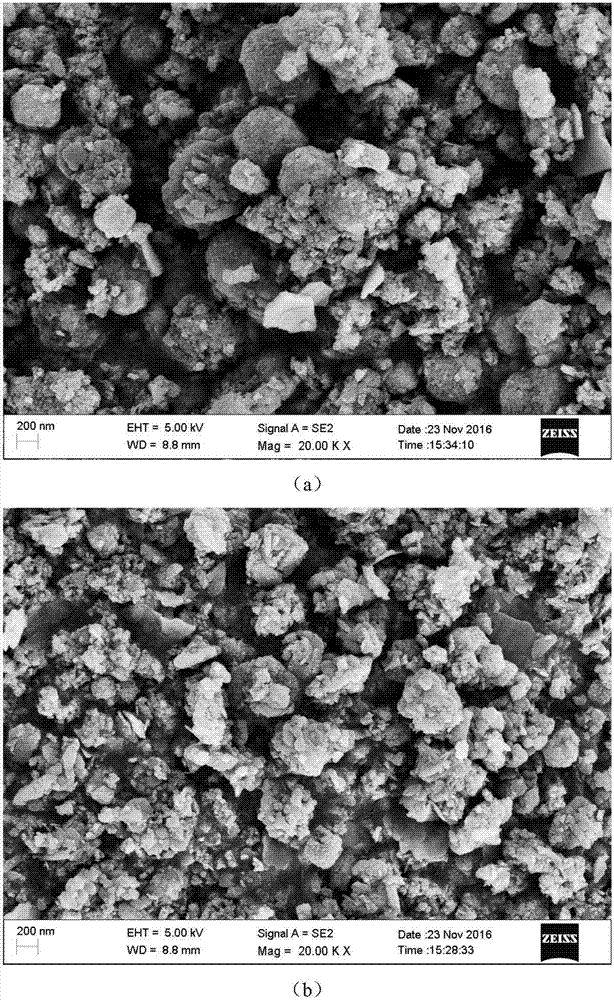

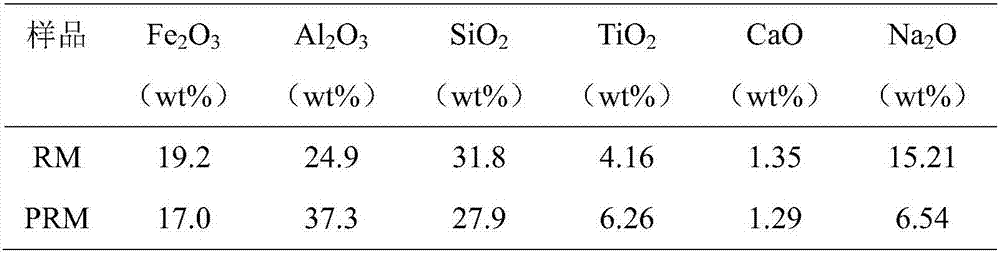

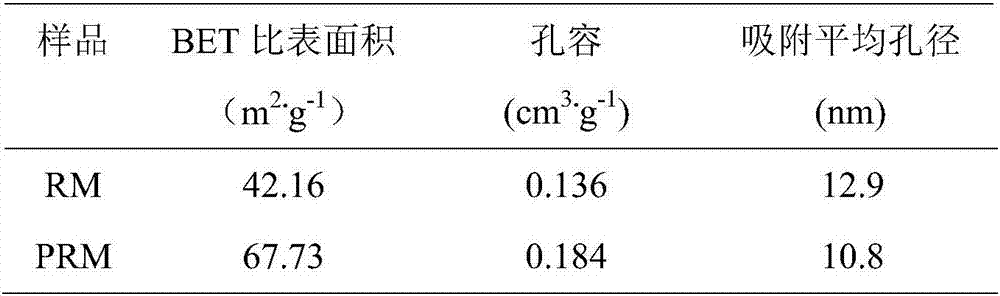

[0037] Preparation of RM catalyst:

[0038] Put 25g of raw red mud into a beaker filled with 150ml of deionized water, add a rotor, stir electromagnetically for 1h, and let stand at room temperature (25°C) for 2h after stirring. After standing, it was washed with deionized water until the pH value was 7, and then it was placed in a dry ventilated box at 105° C. for 12 hours to dry. The RM samples required for the experiment were obtained by grinding.

[0039] Weigh the manganese nitrate solution containing 3.579g of manganese nitrate (mass fraction is 50%), put the cerium nitrate of 2.893g in the beaker, add ethanol to 50ml, and add 50ml of deionized water, place under a magnetic stirrer and fully stir until the cerium nitrate is completely dissolved. Weigh 18.16g of RM, add it to the beaker, and continue stirring with a magnetic stirrer for 1h; at the same time, slowly titrate the beaker with ammonia water to adjust the pH value to 10 and the concentration of ammonia water ...

Embodiment 2

[0051] Preparation of RM catalyst:

[0052] Put 25g of raw red mud into a beaker filled with 150ml of deionized water, add a rotor, stir electromagnetically for 1.5h, and let stand at room temperature (25°C) for 2.5h after stirring. After standing, it was washed with deionized water until the pH value was 7, and then it was placed in a dry ventilated box at 100° C. for 10 hours to dry. The RM samples required for the experiment were obtained by grinding.

[0053] Weigh the manganese nitrate solution containing 3.853g of manganese nitrate (mass fraction is 50%), put 2.512g of cerium nitrate in a beaker, add ethanol to 50ml, and add 50ml of deionized water, place under a magnetic stirrer and stir fully until the cerium nitrate is completely dissolved. Weigh 19.16g of RM, add it to the beaker, and continue stirring with a magnetic stirrer for 1h; at the same time, slowly titrate the beaker with ammonia water to adjust the pH value to 10 and the concentration of ammonia water to...

Embodiment 3

[0055] Preparation of PRM catalyst

[0056] Put 25g of red mud into a beaker filled with 150ml of nitric acid solution, the concentration of nitric acid is 0.5mol L -1 , add the rotor, electromagnetically stir for 1h, and let stand at room temperature for 2h after stirring. After standing, it was washed with deionized water until the pH value was 7, and then placed in a dry ventilated box at 105° C. for 12 hours to dry. The PRM samples required for the experiment were obtained by grinding.

[0057] Weigh the manganese nitrate solution containing 3.579g of manganese nitrate (mass fraction is 50%), put 2.893g of cerium nitrate into a beaker, add ethanol to 50ml, and add 50ml of deionized water, place under a magnetic stirrer and stir fully until the cerium nitrate is completely dissolved. Weigh 18.16g of PRM, add it to the beaker, and continue stirring with a magnetic stirrer for 1h; at the same time, slowly titrate the beaker with ammonia water to adjust the pH value to 10 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com