Making method of sandwich-type composite membrane stent

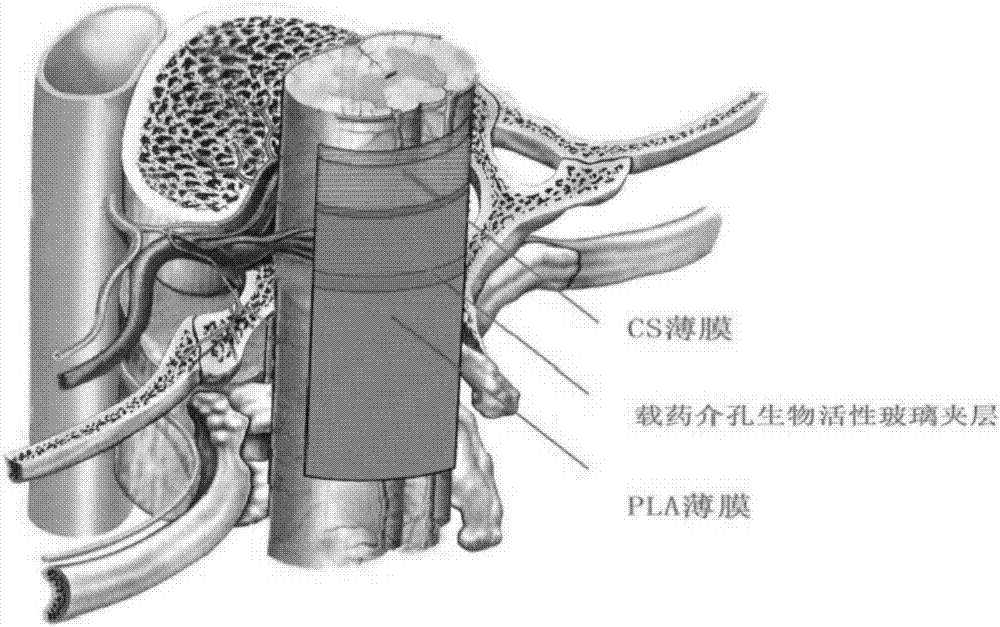

A sandwich-type, production method technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of directional drug release and low drug loading, and achieve the effect of preventing the formation of cerebrospinal fluid leakage and improving the effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

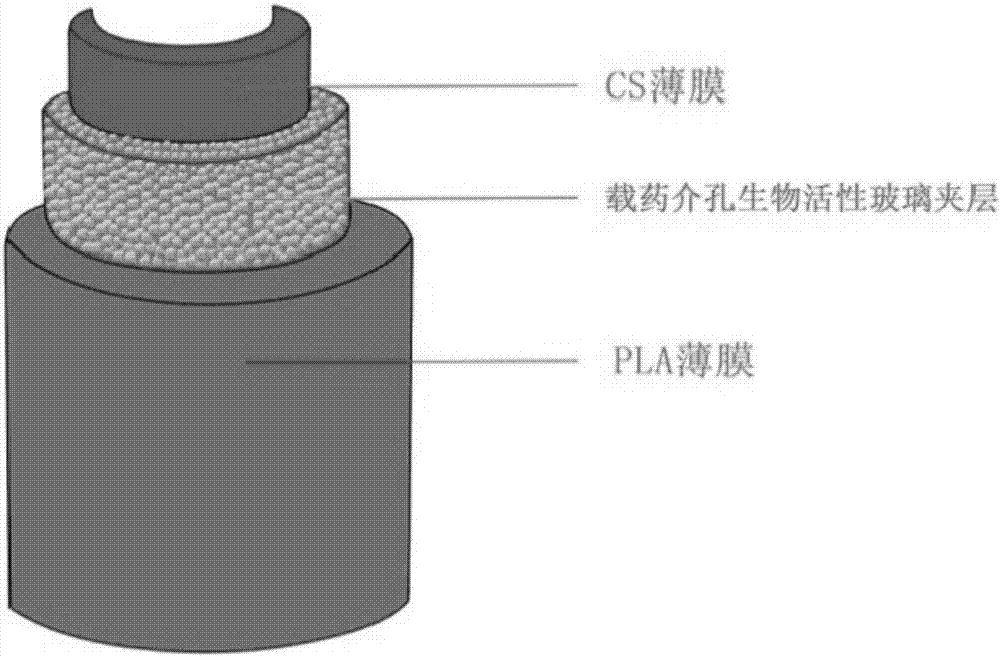

[0041] 1) Make polylactic acid with a certain molecular weight (mass average molecular weight is 5000-1000000, preferably 5000-100000), dissolved in an organic solvent (organic solvents include 1,4-dioxane, acetone, chloroform / ethanol mixed Solvent, dichloromethane, tetrahydrofuran, and a mixed solvent of the above solvents), the concentration is 0.1-10 wt%, and the polylactic acid film is prepared by spin coating, drip coating, etc., as the outer sealing layer;

[0042] 2) Dissolving a chitosan film with a certain molecular weight (mass average molecular weight 5000-1000000, preferably 5000-100000) into an acidic aqueous solution (acids used include hydrochloric acid, acetic acid, nitric acid) at a concentration of 0.1-10 wt%, Prepare chitosan film by spin coating, drip coating, etc., as the inner controlled release layer and stem cell scaffold;

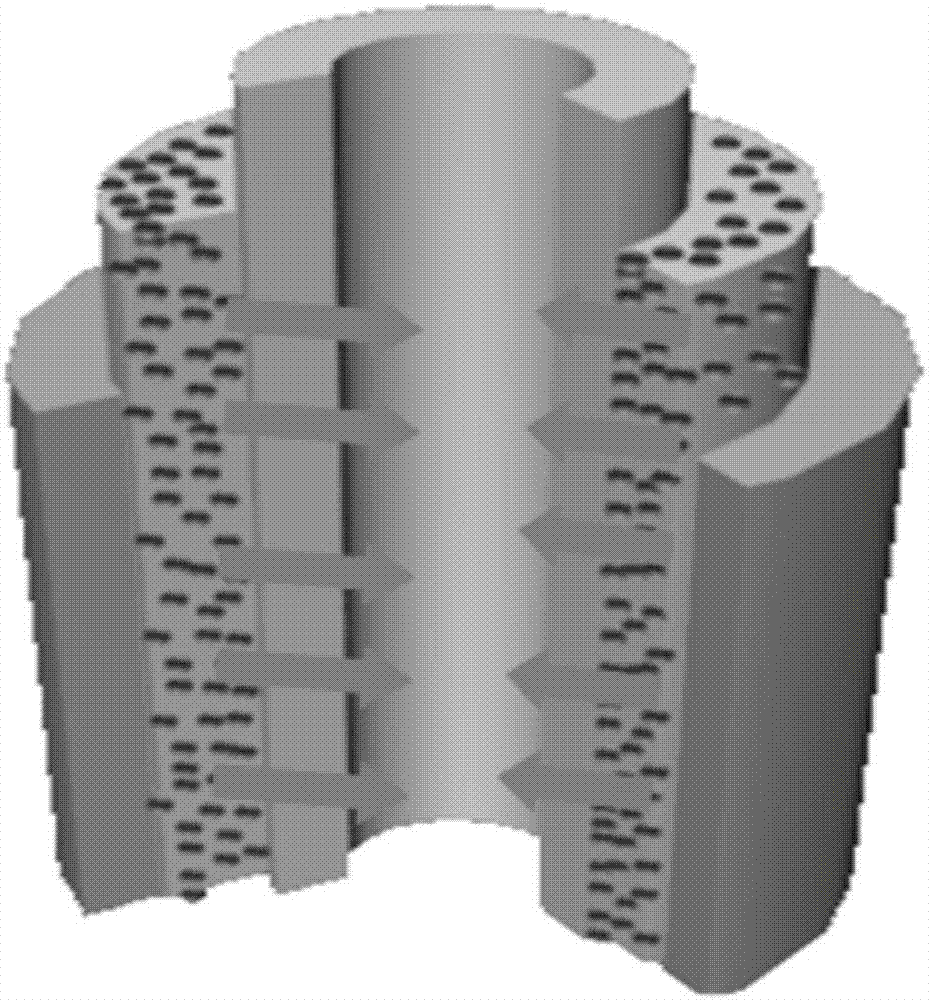

[0043] 3) The stem cell suspension is evenly immersed in the chitosan film in the previous step for cultivation by layer-by-layer ...

Embodiment 2

[0047] Compared with Example 1, the difference of Example 2 is that 5) each layer is adhered with medical bio-glue capable of penetrating nerve growth stimulating factor and stem cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com