Co-N-C/SiO2 composite nanometer catalyst, preparation method thereof and application

A nano-catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, amino compound preparation, etc., can solve the problem of difficult precise control of the size of metal nanoparticles, poor coupling reaction selectivity and catalytic activity, low catalytic activity, etc. problems, to achieve optimal catalytic activity and stability, improve dispersion, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

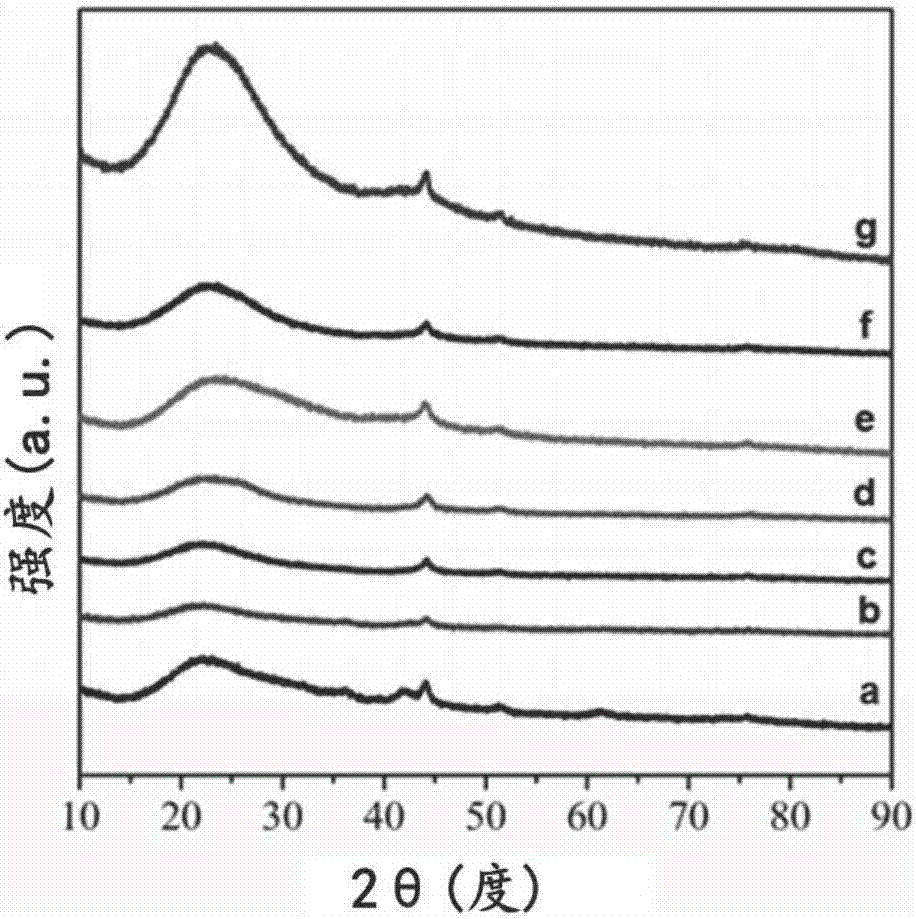

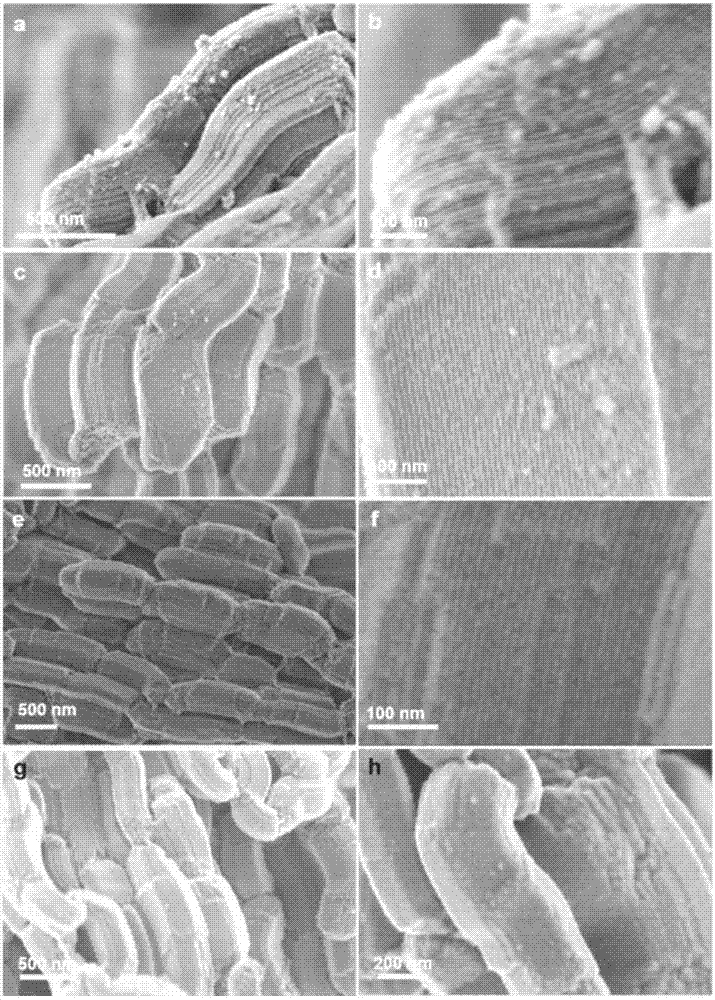

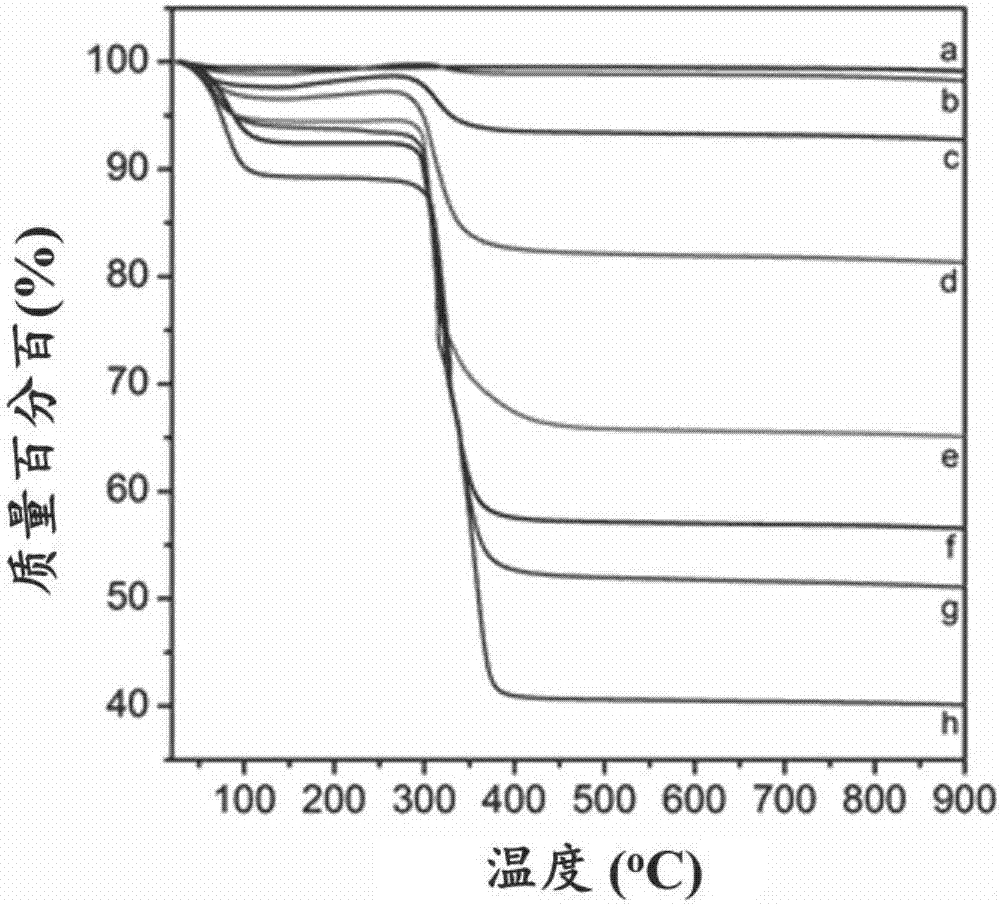

[0037] The invention provides a Co-N-C / SiO 2 The preparation method of composite nano-catalyst comprises:

[0038] Mix the cobalt metal precursor salt, nitrogen-containing organic carbon source and mesoporous silica, and then roast to obtain Co-N-C / SiO 2 Composite nanocatalysts.

[0039] The preparation method disclosed in the present invention can prepare Co-N-C / SiO in one step without using any solvent 2 Composite nano-catalyst, simple and easy to operate.

[0040]The cobalt metal precursor salt is preferably cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), cobalt sulfate heptahydrate (CoSO 4 ·7H 2 O), cobalt chloride hexahydrate (CoCl 2 ·6H 2 O), one or more of cobalt acetate and cobalt acetoacetate. The nitrogen-containing organic carbon source is preferably one or more of amino acids, dopamine and melamine; more preferably histidine (His), arginine (Arg) and glutamic acid (Glu), dopamine and melamine one or more of. If a nitrogen-free organic carbon source is...

Embodiment 1

[0061] Will (Co(NO 3 ) 2 ·6H 2 O, His, and SBA-15 were ground and mixed at a mass ratio of 0.4:0.2:1.0, placed in a tube furnace, heated to 700°C at a heating rate of 5°C / min under a nitrogen atmosphere, and then, at this temperature After 3 hours of lower calcination, it was naturally cooled to room temperature to obtain sample 1.

Embodiment 2

[0063] Will (Co(NO 3 ) 2 ·6H 2 O, His, and SBA-15 were ground and mixed according to the mass ratio of 0.4:0.4:1.0, placed in a tube furnace, heated to 700°C at a heating rate of 5°C / min under a nitrogen atmosphere, and then, at this temperature After 3 hours of lower calcination, it was naturally cooled to room temperature to obtain sample 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com