A kind of epoxy resin-silicon dioxide composite single hole janus hollow microsphere and preparation method thereof

A technology of epoxy resin and silicon dioxide, which is applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of lack of toughness, insufficient strength, and easy cracking of materials, and achieve raw materials The effect of a wide range of sources, high support strength, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0049] The number of carbon atoms in the paraffin wax in Example 4 is 25-35.

Embodiment 1

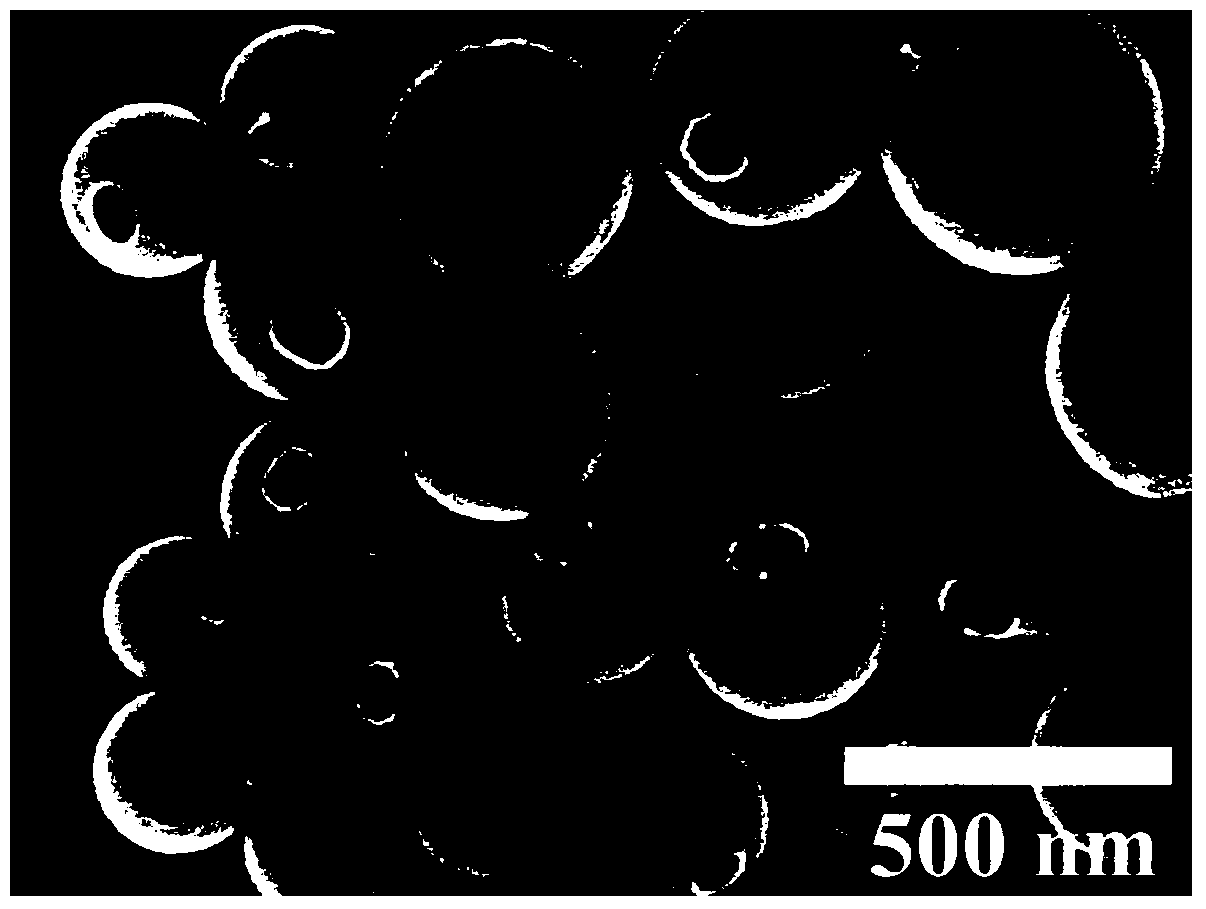

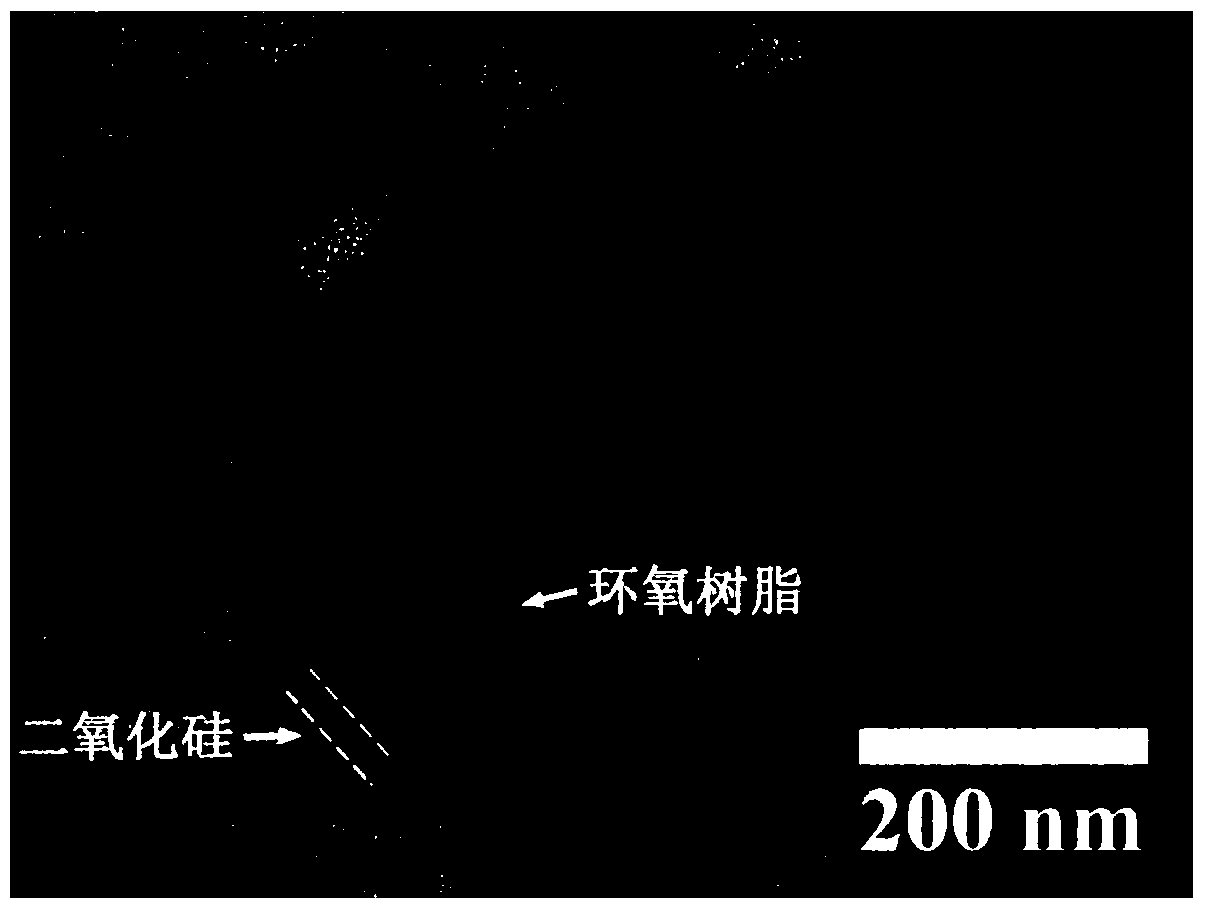

[0050] Example 1, preparation of epoxy resin-silica composite single-hole Janus hollow microspheres

[0051] Prepare epoxy resin-silica composite single-hole Janus hollow microspheres according to the following steps:

[0052] (1) Preparation of epoxy resin prepolymer emulsion

[0053] oil phase

[0054] Epoxy resin E51 1g

[0055] n-Hexadecane 0.2g

[0056] Toluene 2.5g

[0057] water box

[0058] water 24g

[0059] Epoxy resin-polyethylene glycol copolymer 0.3g

[0060] According to the above ratio, dissolve epoxy resin E51 and n-hexadecane in toluene to obtain an oil phase; dissolve epoxy resin-polyethylene glycol copolymer in water to obtain a water phase; mix the oil phase and water phase, 15000rpm shear emulsification for 10min to obtain a stable epoxy resin prepolymer emulsion;

[0061] (2) Preparation of cross-linked epoxy resin single-hole hollow microspheres

[0062] Add 0.1 g of 2-ethyl-4-methylimidazole to the emulsion obtained in step (1), react at 70°C f...

Embodiment 2

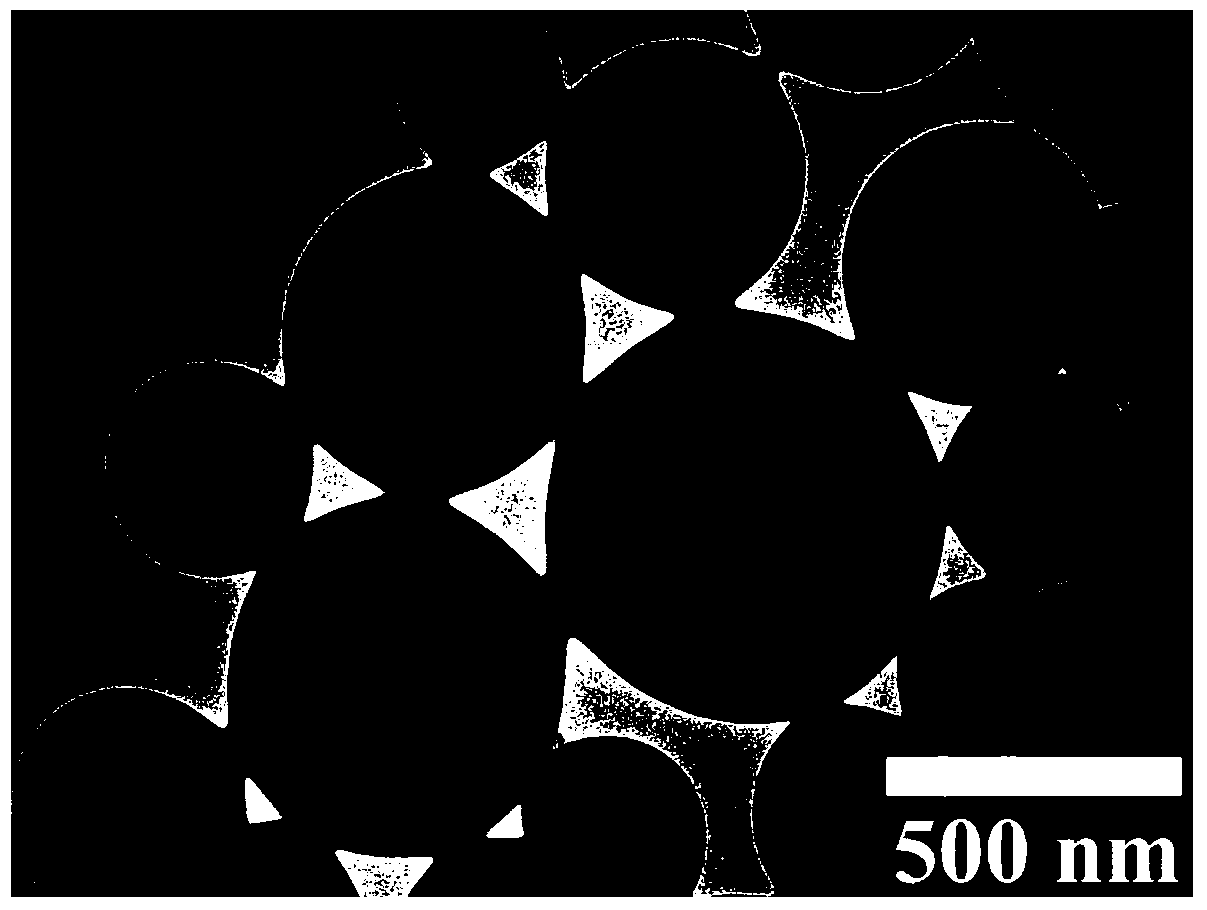

[0066] Example 2, preparation of epoxy resin-silica composite single-hole Janus hollow microspheres

[0067] Prepare epoxy resin-silica composite single-hole Janus hollow microspheres according to the following steps:

[0068] (1) Preparation of epoxy resin prepolymer emulsion

[0069] oil phase

[0070]

[0071]

[0072] water box

[0073] water 30g

[0074] Epoxy resin-polyethylene glycol copolymer 0.2g

[0075] According to the above ratio, epoxy resin E44, epoxy resin E51 and n-octadecane were dissolved in xylene to obtain an oil phase; epoxy resin-polyethylene glycol copolymer was dissolved in water to obtain a water phase; Phase and water phase mixing, ultrasonic emulsification (ultrasonic intensity 200W / cm 2 ) 10min, get stable epoxy resin prepolymer emulsion;

[0076] (2) Preparation of cross-linked epoxy resin single-hole hollow microspheres

[0077] Add 0.05 g of 2-methylimidazole to the emulsion obtained in step (1), react at 60° C. for 24 h, centrifuge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com