A kind of integrated board for fire prevention, thermal insulation and decoration and preparation method thereof

A technology for fire protection, thermal insulation and decorative panels, applied in chemical instruments and methods, colloidal chemistry, colloidal chemistry, etc., can solve the problems of complicated installation and operation, inability to meet the needs of decoration operations, hidden safety hazards, etc., and achieve the effect of shortening the replacement cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

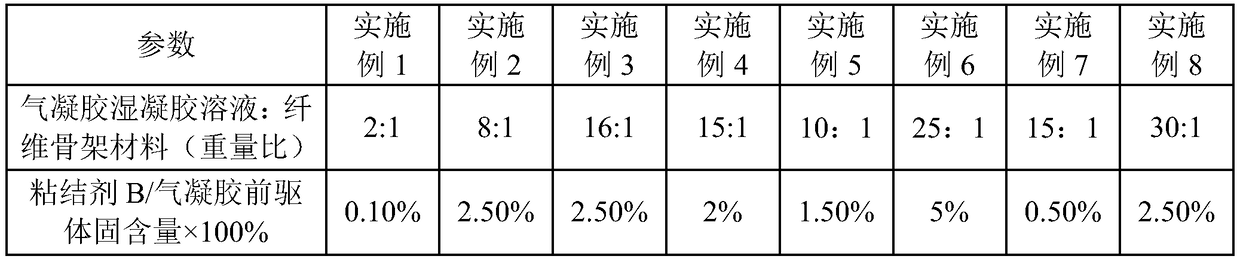

[0088] 1. A formula for fireproof insulation felt, comprising airgel wet gel solution, fiber skeleton material, the weight ratio of airgel wet gel solution and fiber skeleton material is 2 to 30:1;

[0089] The airgel wet gel solution includes an airgel precursor and a binder B, and the amount of the binder added is 0.1 to 5% of the solid content of the airgel precursor;

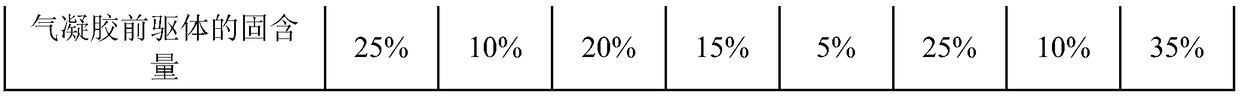

[0090] The solid content of the airgel precursor is 5-35%, which means that the airgel solid content in the airgel precursor is 5-35%;

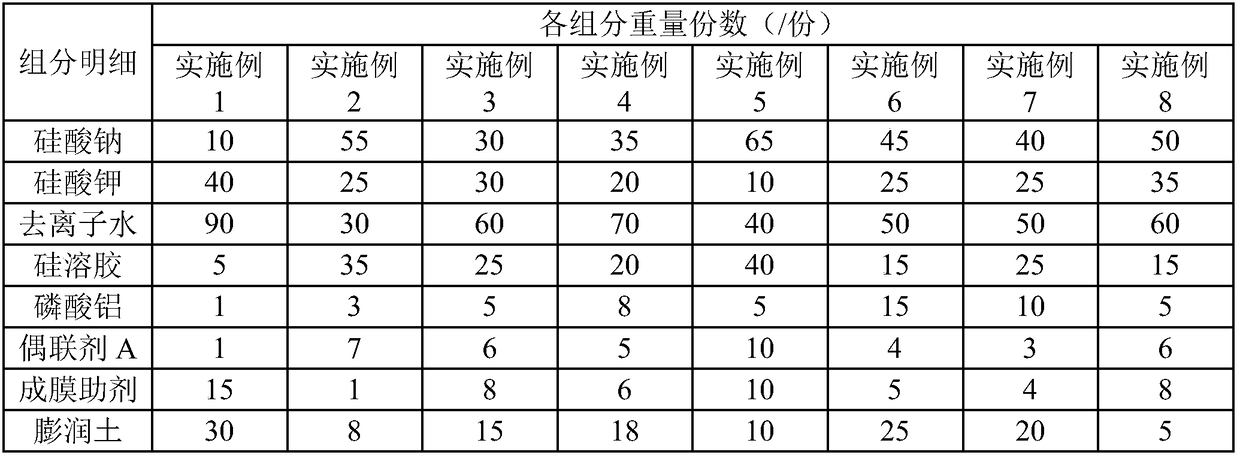

[0091] Binder B, in parts by weight, includes 10-65 parts by weight of sodium silicate, 10-40 parts by weight of potassium silicate, 30-90 parts by weight of deionized deionized water, 5-40 parts by weight of Silica sol, 1-15 parts by weight of aluminum phosphate, 1-10 parts by weight of coupling agent A, 1-15 parts by weight of film-forming aid, and 5-30 parts by weight of bentonite;

[0092] The usage details of each component in Examples 1-8 are shown in Table 1, and th...

Embodiment 9-16

[0158] The preparation method of the fireproof heat preservation and decoration integrated board is characterized in that it includes the following steps: respectively coating the adhesive A on the surface of the fireproof heat insulation felt and the decorative plate, and then pressurizing and bonding the glued surfaces of the two , and a fire-proof, thermal-insulation-decoration integrated board is obtained. The thickness of the adhesive A coated on the surface of the fireproof insulation blanket and the decorative board is 0.4-0.5mm; it is processed by extrusion rollers, and the extrusion rate is 0.1-1.5m / min; The pressurization pressure is 0.05-0.2MPa, and the pressurization time is 3-8h. Before the adhesive A is coated on the surface of the fire-proof heat-preservation felt, acupuncture treatment is carried out on the fire-proof heat-preservation felt, and the needle distance of the needle punching is 1-10mm. In Example 9-16, when preparing the integrated board for fire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com