A kind of oily sludge dewatering agent and its preparation method and dehydration method of oily sludge

A technology of dehydrating agent and oil sludge, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. It can solve the problems of soil and water pollution, increase the burden of prevention and control, and high moisture content, and achieve good Effects of dehydration ability and deoiling ability, good variety of properties, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

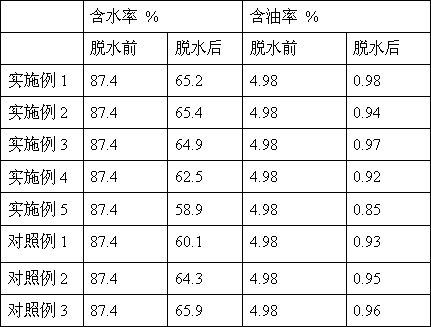

Examples

preparation example 1

[0059] The preparation of preparation example 1 dehydrating agent

[0060] S1. Weigh 30 parts by weight of methacrylamide, 5 parts by weight of acryloyloxyethyltrimethylammonium chloride, 4 parts by weight of formaldehyde, 2 parts by weight of ethylenediamine, 0.6 parts by weight of ammonium persulfate, 1.8 parts by weight of Sodium bisulfite, 1.5 parts by weight of sodium edetate, 4 parts by weight of polyoxyethylene lauryl ether (20), 0.4 parts by weight of azobisisobutyronitrile, 4.5 parts by weight of acrylic acid and 50 parts by weight of deionized water;

[0061] S2. At room temperature, add methacrylamide, acryloyloxyethyltrimethylammonium chloride, ammonium persulfate, azobisisobutyronitrile, formaldehyde, ethylenediamine and sodium bisulfite to deionized water, and then The temperature was raised to 50°C under stirring, and the reaction was fully stirred for 50 minutes to obtain a reaction liquid;

[0062] S3. Add sodium ethylenediamine tetraacetate, polyoxyethylene ...

preparation example 2

[0063] The preparation of preparation example 2 dehydrating agent

[0064] S1. Weigh 40 parts by weight of methacrylamide, 2 parts by weight of acryloyloxyethyltrimethylammonium chloride, 6 parts by weight of formaldehyde, 1 part by weight of ethylenediamine, 1.2 parts by weight of ammonium persulfate, 1.2 parts by weight of Sodium bisulfite, 2.5 parts by weight of sodium edetate, 2 parts by weight of polyoxyethylene lauryl (20) ether, 0.8 parts by weight of azobisisobutyronitrile, 3.5 parts by weight of acrylic acid and 60 parts by weight of deionized water;

[0065] S2. At room temperature, add methacrylamide, acryloyloxyethyltrimethylammonium chloride, ammonium persulfate, azobisisobutyronitrile, formaldehyde, ethylenediamine and sodium bisulfite to deionized water, and then The temperature was raised to 60°C under stirring, and the reaction was fully stirred for 30 minutes to obtain a reaction liquid;

[0066] S3. Add sodium ethylenediamine tetraacetate, polyoxyethylene l...

preparation example 3

[0067] Preparation Example 3: Preparation of Dehydrating Agent

[0068] S1. Weigh 35 parts by weight of methacrylamide, 3.5 parts by weight of acryloyloxyethyltrimethylammonium chloride, 5 parts by weight of formaldehyde, 1.5 parts by weight of ethylenediamine, 0.9 parts by weight of ammonium persulfate, 1.5 parts by weight of Sodium bisulfite, 2 parts by weight of sodium edetate, 3 parts by weight of polyoxyethylene lauryl alcohol (20) ether, 0.6 parts by weight of azobisisobutyronitrile, 4 parts by weight of acrylic acid and 55 parts by weight of deionized water;

[0069] S2. At room temperature, add methacrylamide, acryloyloxyethyltrimethylammonium chloride, ammonium persulfate, azobisisobutyronitrile, formaldehyde, ethylenediamine and sodium bisulfite to deionized water, and then The temperature was raised to 55°C under stirring, and the reaction was fully stirred for 40 minutes to obtain a reaction liquid;

[0070] S3. Add sodium ethylenediamine tetraacetate, polyoxyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com