Wall body material and preparation method thereof

A technology of wall materials and raw materials, applied in the field of building materials, can solve problems such as low bulk density, and achieve the effect of reducing the overall load, light weight, and surface sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

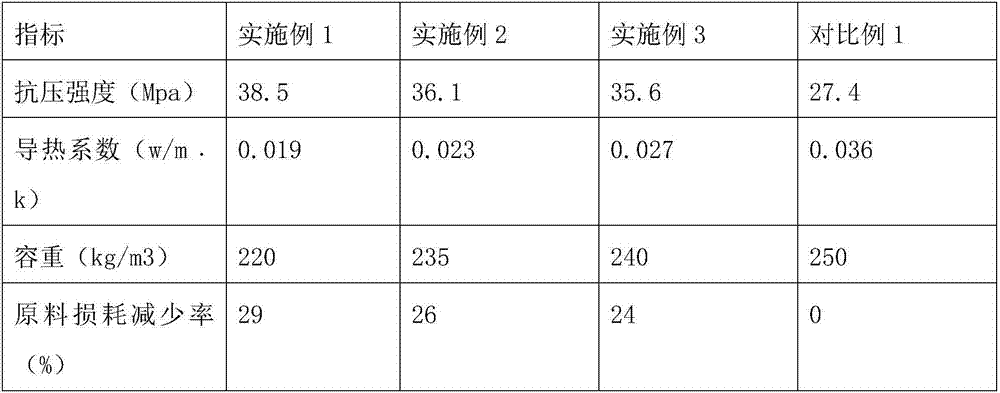

Examples

Embodiment 1

[0042] A wall material, comprising the following raw materials in parts by weight: 65 parts of ceramic polishing slag, 20 parts of feldspar, 6 parts of calcined talc, 15 parts of red mud, 6 parts of lithium feldspar, 11 parts of dikai stone, and 1.5 parts of silicon carbide , 2.5 parts of barium carbonate, 23 parts of shale ash, 20 parts of expanded perlite, 20 parts of quartz sand, 15 parts of floating beads, 19 parts of waste foamed cement, 21 parts of waste polyethylene foam, 23 parts of synthetic fiber, glass wool 17 parts, 0.5 parts of retarder, 0.6 parts of foaming agent, 0.4 parts of water reducing agent and 6 parts of water.

[0043] The wall material prepared under the formula has reached the optimum in terms of compressive strength, thermal insulation, bulk density, environmental protection and energy saving.

[0044] Waste foamed cement and waste polyethylene foam are added to the raw materials. These construction wastes have been shelved in the city for a long time...

Embodiment 2

[0063] A wall material, comprising the following raw materials in parts by weight: 50 parts of ceramic polishing slag, 10 parts of feldspar, 2 parts of calcined talc, 10 parts of red mud, 2 parts of lithium feldspar, 7 parts of dikai stone, and 1 part of silicon carbide , 1.5 parts of barium carbonate, 15 parts of shale ash, 17 parts of expanded perlite, 19 parts of quartz sand, 13 parts of floating beads, 17 parts of waste foamed cement, 19 parts of waste polyethylene foam, 12 parts of synthetic fiber, glass wool 13 parts, 0.3 parts of retarder, 0.3 parts of foaming agent, 0.3 parts of water reducing agent and 5 parts of water.

[0064] Waste foamed cement and waste polyethylene foam are added to the raw materials of the present invention. These construction wastes have been left in the city for a long time, not only occupying urban land, but also polluting the local environment. Now these construction wastes are recycled to achieve energy saving and environmental protection ...

Embodiment 3

[0083] A wall material, comprising the following raw materials in parts by weight: 80 parts of ceramic polishing slag, 30 parts of feldspar, 10 parts of calcined talc, 20 parts of red mud, 10 parts of lithium feldspar, 15 parts of dikai stone, and 2 parts of silicon carbide , 3.5 parts of barium carbonate, 31 parts of shale ash, 23 parts of expanded perlite, 21 parts of quartz sand, 17 parts of floating beads, 21 parts of waste foamed cement, 23 parts of waste polyethylene foam, 34 parts of synthetic fiber, glass wool 21 parts, 0.7 parts of retarder, 0.9 parts of foaming agent, 0.5 parts of water reducing agent and 7 parts of water.

[0084] Waste foamed cement and waste polyethylene foam are added to the raw materials. These construction wastes have been shelved in the city for a long time, not only occupying urban land, but also polluting the local environment. Now these construction wastes are recycled to achieve the purpose of energy saving and environmental protection.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com