Processing method of nutritional and healthy lotus root powder

A processing method and lotus root flour technology are applied in the processing field of high-nutrition and healthy lotus root flour, which can solve problems such as the influence of lotus root nutritional value on the health of consumers, and achieve the effects of reducing bacterial damage, shortening time consumption, and increasing nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

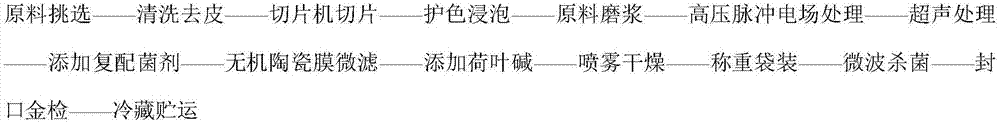

Method used

Image

Examples

Embodiment 1

[0046] (1) Raw material selection: select lotus root raw materials, and select raw materials that are free from insect pests, damage, disease, and peculiar smell, and have normal color.

[0047] (2) Cleaning and peeling: the operator uses a kitchen knife to remove the lotus root knots, and it is required to remove 2-3 cm of the adjacent lotus root joints. Finally, the lotus root raw material is passed through the peeling and washing machine, and the processing capacity is about 600kg / h.

[0048] (3) Slicing: quickly send the peeled lotus root raw materials into the slicer to avoid contact with air to make it oxidative and discolored. Adjust the setting of the slicer according to the needs, the thickness of thin slices is 2-3mm, and the diameter is 3-4.5cm; the thickness of medium slices is 7-8mm, and the diameter is 5-6cm; Weight 60g±5g.

[0049] (4) Soaking for color protection: Soak the lotus root slices in the soaking pool for 4 hours. The ratio of the soaking solution i...

Embodiment 2

[0063] Change the powder addition amount in the step (9) among the embodiment 1 into 1% of the lotus root slurry weight. Others are the same as embodiment 1.

Embodiment 3

[0065] Change the powder addition amount in the step (9) among the embodiment 1 into 5% of the lotus root slurry weight. Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com