Preparation method for chlorine-doped carbon quantum dot/g-C3N4 nano sheet composite material for high-effectively degrading antibiotics

A technology of chlorocarbon quantum and composite materials, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. problem, to achieve the effect of wide light absorption range, large specific surface area, and excellent photocatalytic degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

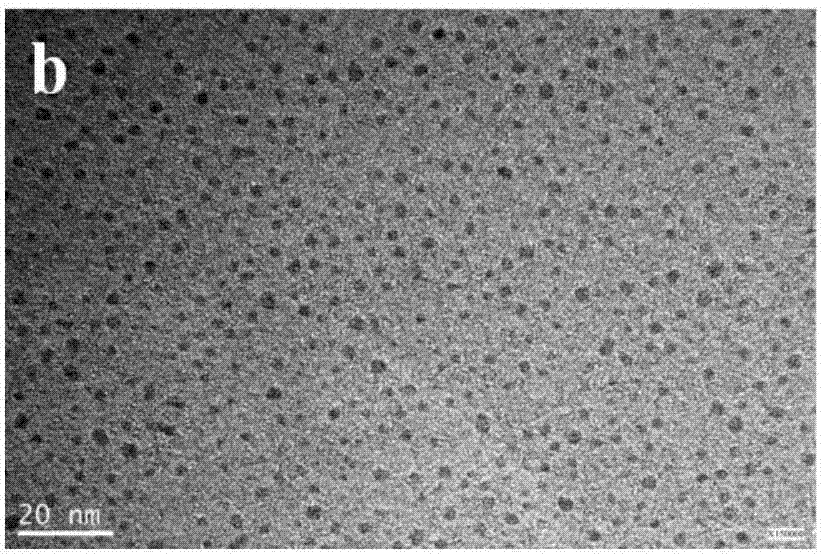

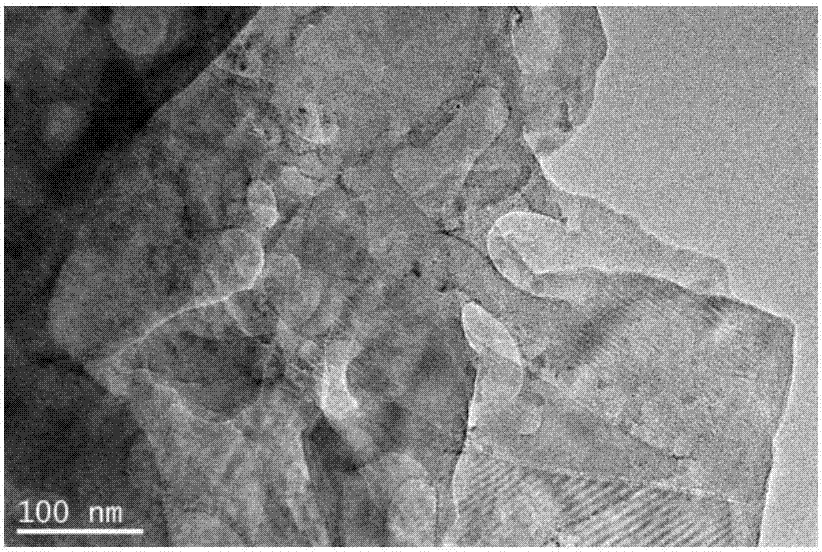

Image

Examples

Embodiment 1

[0027] A Chlorine-doped Carbon Quantum Dot / g-C for Efficient Degradation of Antibiotics 3 N 4 The preparation method of nano sheet composite material, concrete steps are as follows:

[0028] (1) g-C 3 N 4 Preparation of nanosheets: Using melamine as raw material, put the raw material into a crucible and place it in a muffle furnace, and calcinate at 550°C for 4 hours to obtain the original g-C 3 N 4 ; the obtained original g-C 3 N 4 Open calcination at 475°C for 2 hours, that is, two calcinations to obtain g-C 3 N 4 Nanosheets;

[0029] (2)g-C 3 N 4 Protonation of nanosheets: the g-C prepared in step (1) 3 N 4 The nanosheets were dispersed in 3mol / L HCL solution, stirred for 3 hours, and centrifuged to obtain protonated g-C 3 N 4 Nanosheets;

[0030] (3) Preparation of chlorine-doped carbon quantum dots: put 30mL of ethylene glycol into the reactor, heat to 200°C, keep warm for 5h, cool to room temperature, and centrifuge the solution in the reactor to obtain th...

Embodiment 2

[0036] The preparation method of this example is the same as that of Example 1, except that the volume of thionyl chloride in step (3) is modified from 250uL to 350uL.

[0037] Chlorine-doped carbon quantum dots / g-C prepared in this embodiment 3 N 4 The nanosheet composite material has strong photocatalytic ability, and can completely degrade 10mg / L tetracycline hydrochloride (TC) within 120min under visible light conditions, and the kinetic constant of degrading TC solution is 9.72×10 -3 min -1 .

Embodiment 3

[0039] The preparation method of this example is the same as that of Example 1, except that the volume of thionyl chloride in step (3) is modified from 250uL to 450uL.

[0040] Chlorine-doped carbon quantum dots / g-C prepared in this embodiment 3 N 4 Nanosheet composite material, with strong photocatalytic ability, can completely degrade 10mg / L tetracycline hydrochloride (TC) within 120min under visible light conditions, and the kinetic constant of degrading TC solution is 10.15×10 -3 min -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinetic constant | aaaaa | aaaaa |

| Kinetic constant | aaaaa | aaaaa |

| Kinetic constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com