Pretreatment method for enrichment and solid-phase derivatization of sugar phosphate substances

A technology for phosphate sugars and sugar substances, which is applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means, so as to improve the detection sensitivity of mass spectrometry, shorten the time required, and avoid the use of excessive derivative reagents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

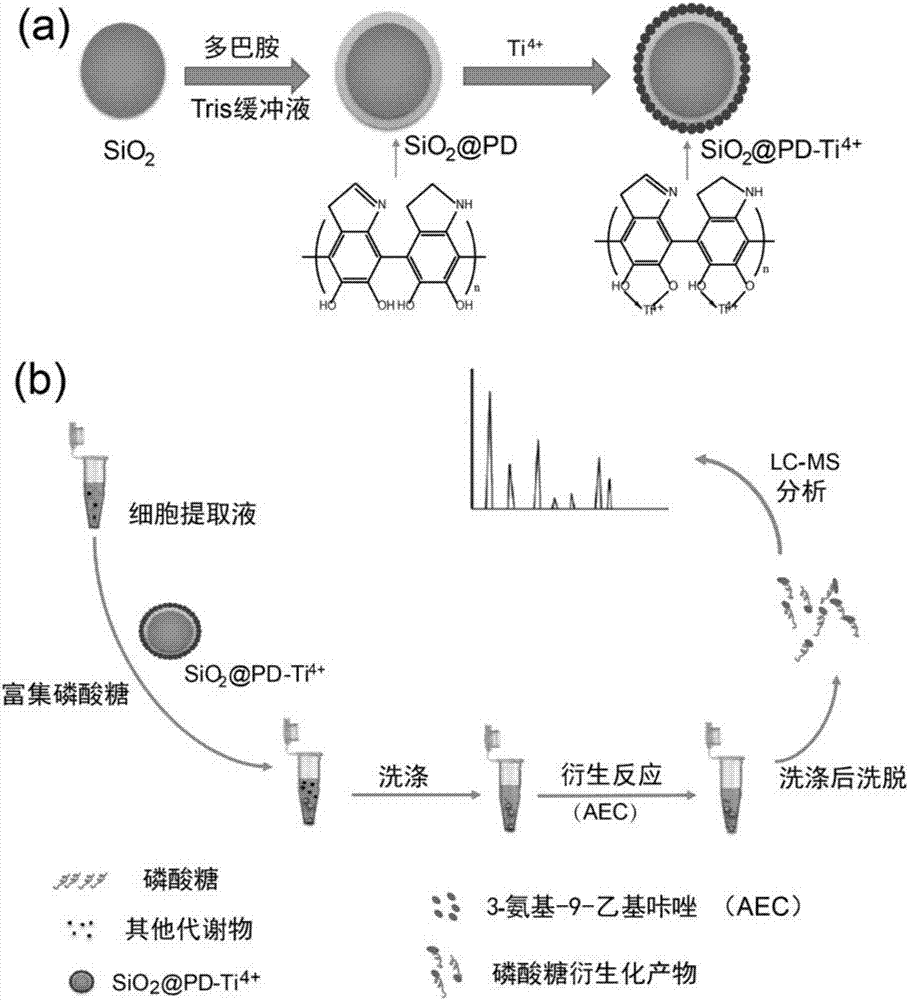

[0016] Embodiment 1. immobilized metal affinity chromatography material SiO 2 @PD-Ti 4 The synthesis of + and its enrichment and derivation process for phosphate sugars.

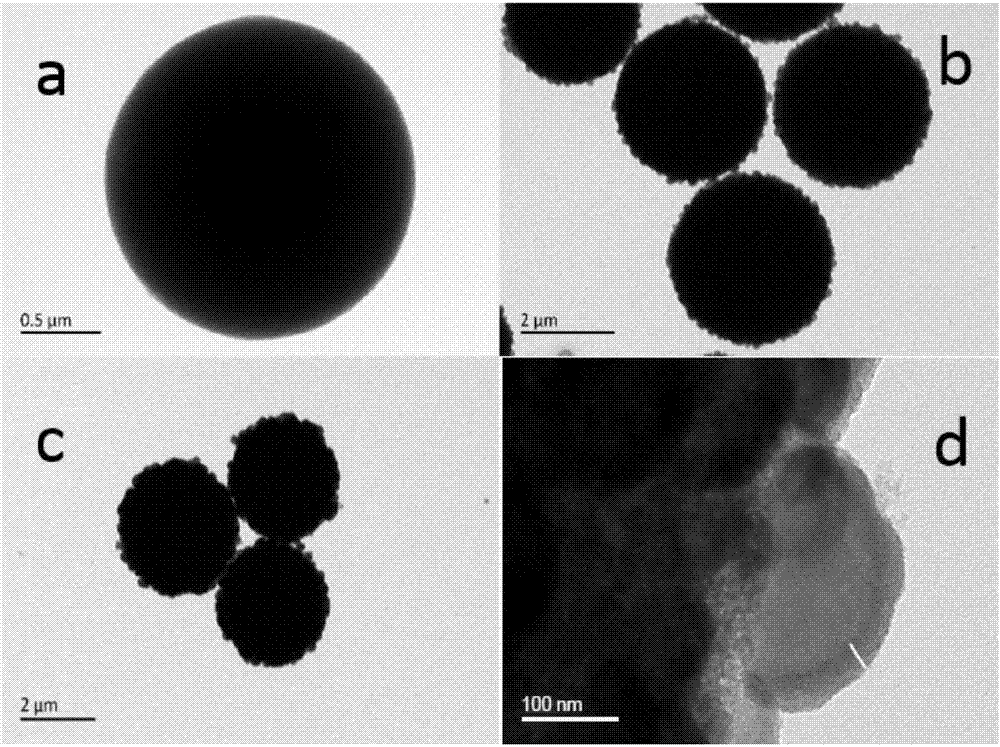

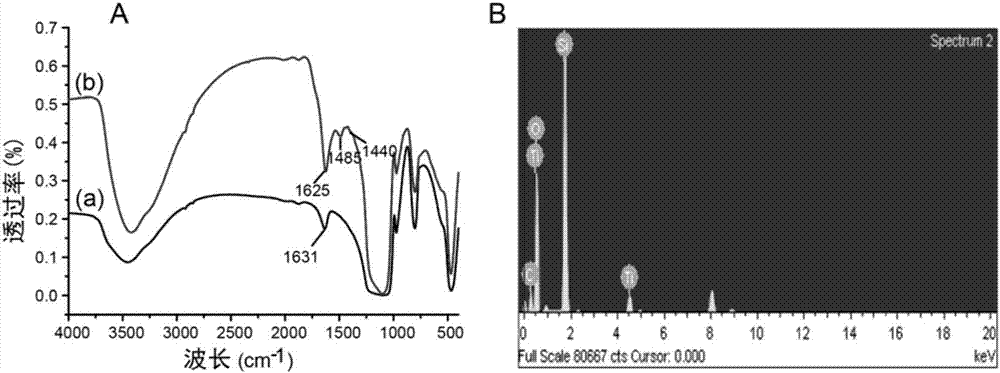

[0017] The first step to synthesize immobilized metal affinity chromatography material SiO 2 @PD-Ti 4+ : 200mg SiO2 2 (particle size 3μm) was dispersed in 40mL of dopamine aqueous solution with a concentration of 2mg / mL, and 40mL Tris buffer (pH 8.5) was quickly added under magnetic stirring, and reacted for 10 hours at a water bath temperature of 40°C under magnetic stirring conditions, and SiO was obtained after washing with water. 2 @PD microspheres. Then SiO 2 @PD dispersed in 80mL of Ti(SO 4 ) 2 In the solution, the reaction was continued for 3 hours at a water bath temperature of 40°C under magnetic stirring conditions, and SiO was obtained after washing with water. 2 @PD-Ti 4+ Microspheres. Synthesis schematic see figure 1 .

[0018] The second enrichment derivation process: take 6-phospha...

Embodiment 2

[0019] Example 2. Selective Enrichment of Phosphosaccharides in Derived Cells and LC-MS Analysis

[0020](1) Cell pretreatment: 7721 liver cancer cells were taken out from the incubator, quenched instantly with liquid nitrogen, and washed 3 times with PBS buffer. Add 1mL of methanol, scrape the cells and transfer them to the EP tube, vortex for 30s, then add 400μL of ultrapure water, vortex for 30s, finally add 1mL of chloroform, and vortex for 30s. After standing still for 1 min, centrifuge at 15000 rpm / min for 10 min. Take 900 μL of supernatant and freeze-dry. Add 4mL sample solution (by ACN / H 2 O (65 / 35, v / v) solution was prepared by adding a final concentration of 2% (v / v) formic acid (FA) and a final mass fraction of 0.4% glutamic acid) for reconstitution.

[0021] (2) Material pretreatment process: take 10mg SiO 2 @PD-Ti 4+ Material, with sample solution (by ACN / H 2 O (65 / 35, v / v) solution was prepared by adding a final concentration of 2% (v / v) formic acid (FA) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com