A kind of preparation method of tin oxide-based thin film varistor

A varistor, tin oxide-based technology, applied in varistor cores, varistors, resistors, etc., can solve the problems of difficult deposition of tin oxide thin films and VFO grain boundary layers, and achieve operational methods Ease of use, controlled conditions, and the effect of mild heat soak conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

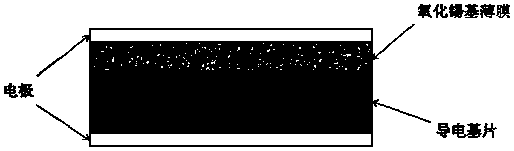

[0035] The preparation method of the tin oxide-based film varistor proposed by the present invention comprises the following steps and content:

[0036] (1) In radio frequency magnetron sputtering equipment, pure tin oxide sintered ceramics or one or more composite tin oxide sintered ceramics of metal Cu, Zn, Cr, Mn are used as matrix targets, and metal Cu, Zn, Cr One or more of Mn and its oxides are doped targets, which are respectively fixed to the corresponding target positions; the clean conductive substrate is fixed on the sample stage; the mechanical pump is turned on to a low vacuum of 0.1Pa , and then turn on the molecular pump until the system vacuum reaches 2×10 -4 Above Pa. Among them, the general formula of pure tin oxide sintered ceramics is SnO n , n is between 1.6-2.0; the substrate substrate is one of highly doped conductive silicon, zinc, copper, and platinum.

[0037] (2) Introduce high-purity argon, adjust the sputtering pressure and glow the pre-sputteri...

Embodiment 1

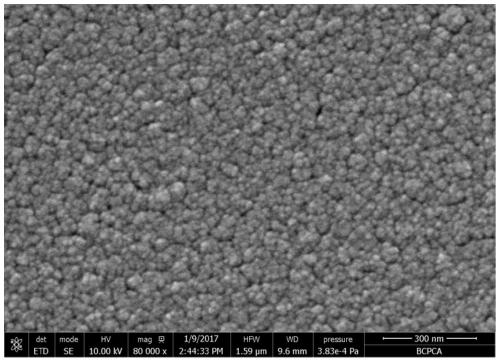

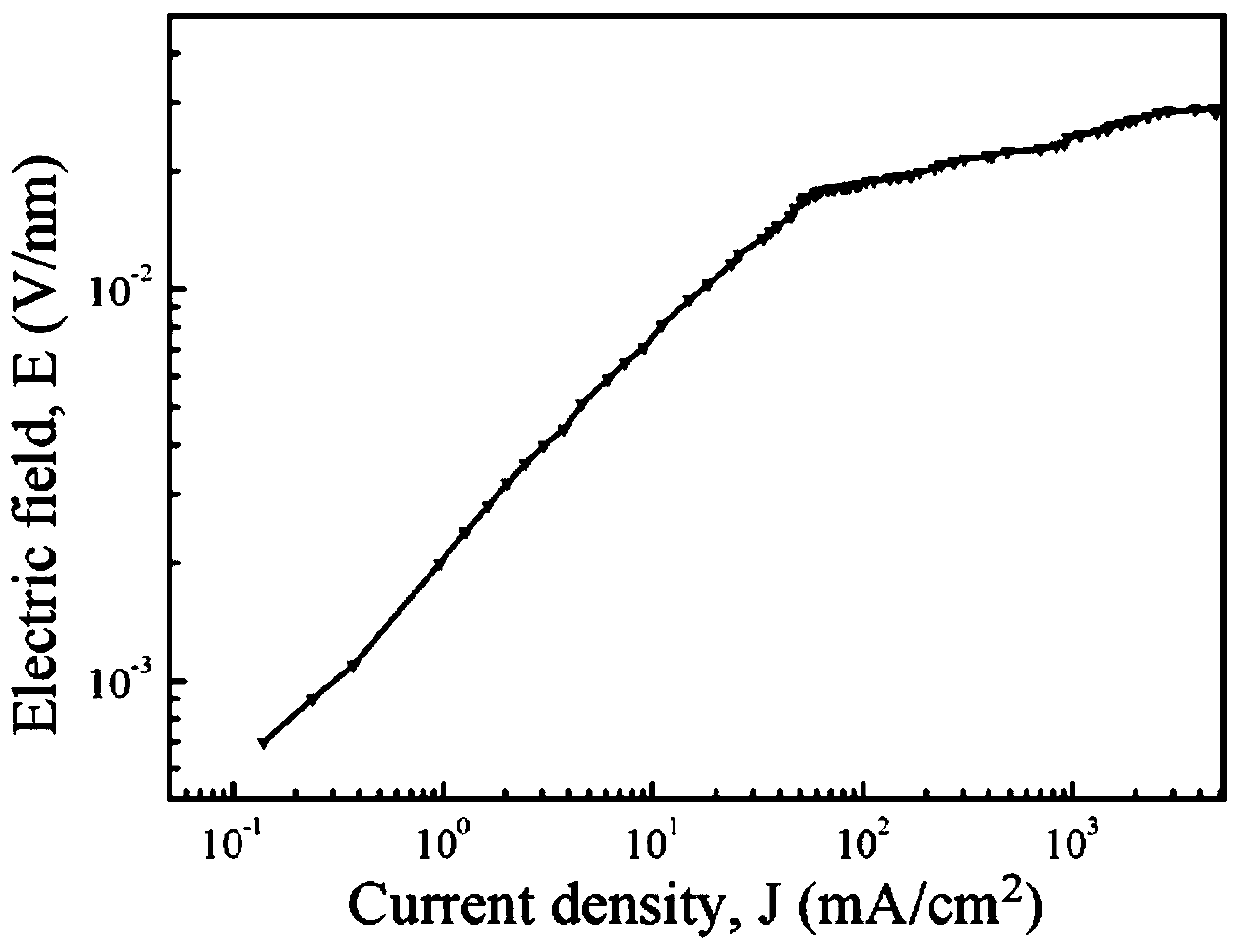

[0046] Example 1: Fix the Mn-doped tin oxide target and the clean highly doped conductive silicon wafer on the corresponding positions of the radio frequency magnetron sputtering equipment, close the chamber, first turn on the mechanical pump to a low vacuum of 0.1Pa, and then Turn on the molecular pump until the vacuum of the system reaches 2×10 -4 Above Pa. Introduce 99.99vol.% high-purity argon, adjust the sputtering pressure to 1.0Pa and start the glow, and perform 2min pre-sputtering; when the glow stabilizes, inject 99.99vol.% high-purity oxygen, control 2 The / Ar volume ratio is 1:1, and then the target shutter is opened to start depositing a thin film on the substrate. The sputtering process was carried out at ambient temperature, where the sputtering power was 80W, the sputtering pressure was 1.0Pa, and the sputtering time was 40min. Finally, a Mn-doped tin oxide-based thin film was deposited. Then, the prepared Mn-doped tin oxide-based film was embedded in analytic...

Embodiment 2

[0048] Example 2: the anoxic SnO 1.65 The target material and the clean highly doped conductive silicon wafer are respectively fixed on the corresponding positions of the radio frequency magnetron sputtering equipment, the chamber is closed, the mechanical pump is turned on to pump to a low vacuum of 0.1Pa, and then the molecular pump is turned on to pump to a system vacuum of 2 ×10 -4 Above Pa. Introduce 99.99vol.% high-purity argon, adjust the sputtering pressure to 1.0Pa and start the glow, and perform 10min pre-sputtering; when the glow stabilizes, inject 99.99vol.% high-purity oxygen, control O 2 / Ar volume ratio is 1:5, then open the target shutter and start to deposit thin film on the substrate. The sputtering process was carried out at ambient temperature, where the sputtering power was selected to be 180W, the sputtering pressure was 3.0Pa, and the sputtering time was 60min. Finally, an oxygen-deficient tin oxide film was deposited. Then, the prepared oxygen-defici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com