Anticorrosion electroplated nickel layer sealing agent

A technology of electroplating nickel and sealing agent, which is applied in the field of corrosion-resistant electroplating nickel layer sealing agent, which can solve the problems of electroplating nickel layer pores and other problems, and achieve the effects of strong adhesion, high corrosion resistance, and long salt spray test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

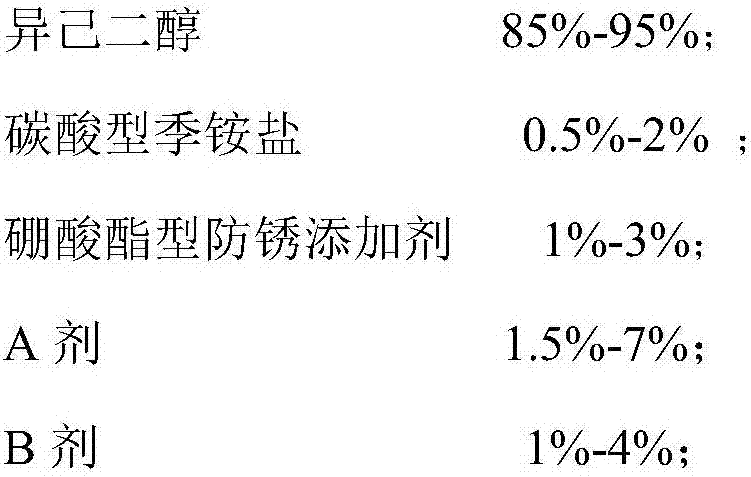

[0022] A kind of anti-corrosion electroplating nickel layer sealing agent, comprises following mass percentage composition:

[0023]

[0024]

[0025] Using the above formula, soak iron-nickel-plated workpieces at room temperature for 5 minutes according to the working solution composed of sealing agent and water at a ratio of 1:10, and then dry them at 80°C. After standing for 24 hours, conduct a salt spray test on the workpiece for 360 hours.

Embodiment 2

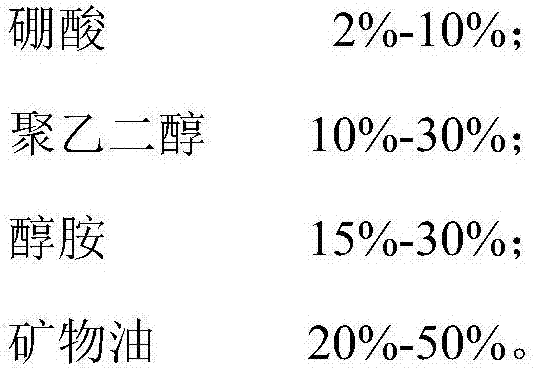

[0027] A kind of anti-corrosion electroplating nickel layer sealing agent, comprises following mass percentage composition:

[0028]

[0029] Using the above formula, soak iron-nickel-plated workpieces at room temperature for 5 minutes according to the working solution composed of sealing agent and water at a ratio of 1:10, and then dry them at 80°C. After standing for 24 hours, conduct a salt spray test on the workpiece for 340 hours.

Embodiment 3

[0031] A kind of anti-corrosion electroplating nickel layer sealing agent, comprises following mass percentage composition:

[0032]

[0033] Using the above formula, soak iron-nickel-plated workpieces at room temperature for 5 minutes according to the working solution composed of sealant and water at a ratio of 1:10, and then dry them at 80°C. After standing for 24 hours, conduct a salt spray test on the workpiece for 313 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com