Preparing method for aluminum base graphene and carbon nano tube composite heat dissipation material

A carbon nanotube composite and heat-dissipating material technology, applied in heat exchange materials, chemical instruments and methods, electrolytic coatings, etc., can solve the problems of inconsistency, time-consuming and energy-consuming, material performance degradation, etc., and prolong the service life. , the effect of improving the heat dissipation coefficient and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

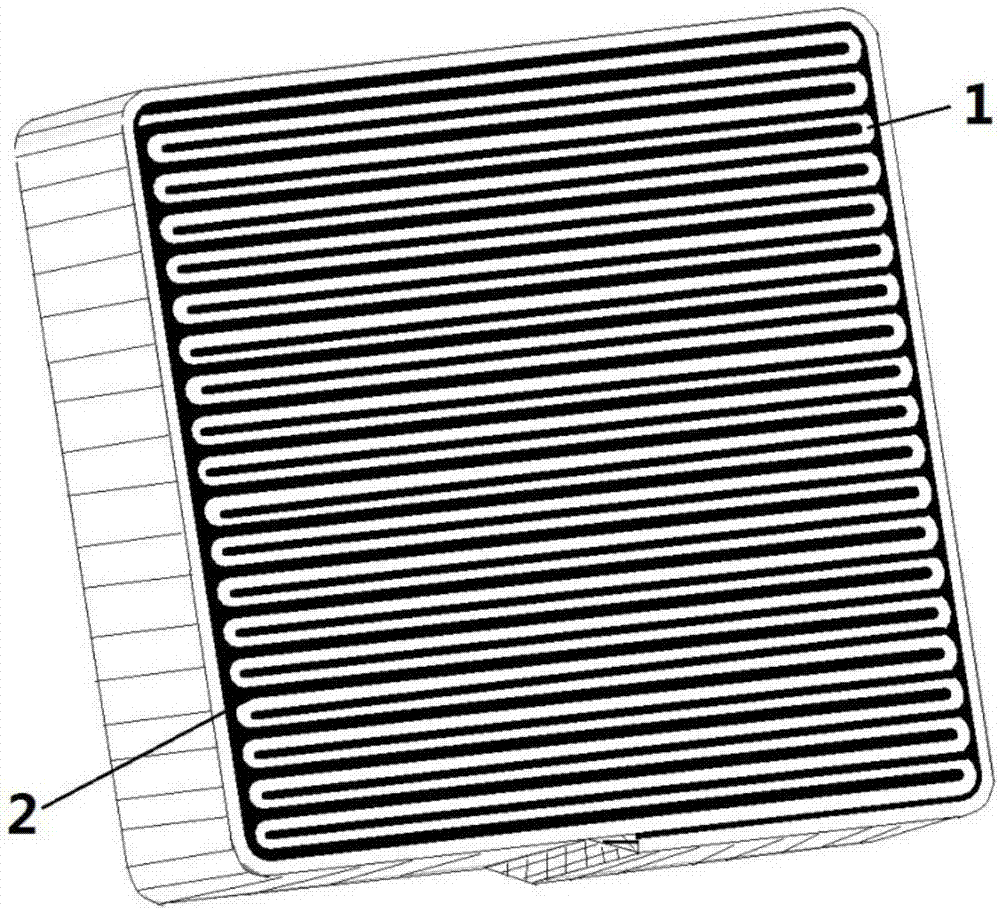

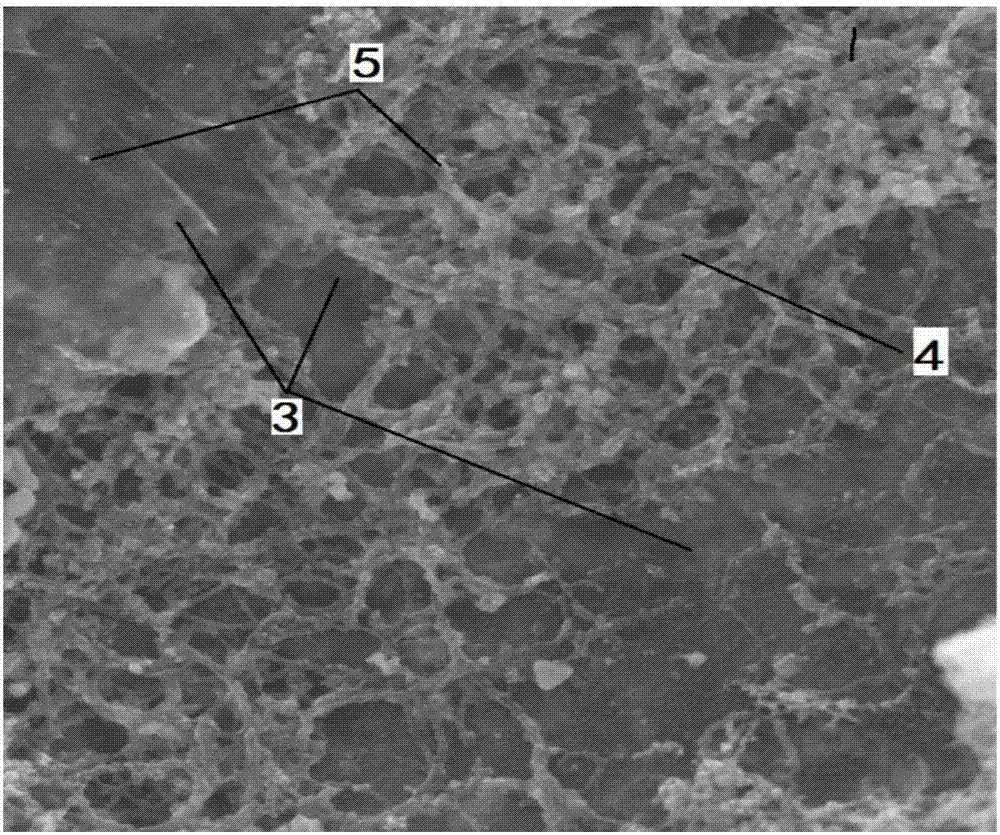

[0021] A preparation method of aluminum-based graphene and carbon nanotube composite heat dissipation material, characterized in that it comprises the following steps:

[0022] (1) put into the same amount of graphene powder and carbon nanotube respectively in dehydrated ethanol solution, be made into the mixed solution that concentration is 0.02mg / ml graphene, carbon nanotube, then add aluminum salt solution, be made into The mixed solution of aluminum salt graphene and carbon nanotubes with an aluminum salt concentration of 0.6 mg / ml is dispersed by ultrasonic waves for 3 hours to obtain a mixed electrophoretic solution of uniformly dispersed aluminum salt graphene and carbon nanotubes;

[0023] (2) Ultrasound an aluminum sheet with a thickness of 0.01 mm in absolute ethanol solution for 10 minutes, then soak it in 5% dilute nitric acid for 0.5 min, rinse it with deionized water several times, and use it as the cathode after drying;

[0024] (3) With the graphite sheet equiv...

Embodiment 2

[0030] A preparation method of aluminum-based graphene and carbon nanotube composite heat dissipation material, characterized in that it comprises the following steps:

[0031] (1) put into the same amount of graphene powder and carbon nanotube respectively in dehydrated ethanol solution, be made into the mixed solution that concentration is 0.08mg / ml graphene, carbon nanotube, then add aluminum salt solution, be made into The mixed solution of aluminum salt graphene and carbon nanotubes with an aluminum salt concentration of 0.4 mg / ml is dispersed by ultrasonic waves for 5 hours to obtain a mixed electrophoretic solution of uniformly dispersed aluminum salt graphene and carbon nanotubes;

[0032] (2) Ultrasonicate an aluminum sheet with a thickness of 0.05 mm in absolute ethanol solution for 8 minutes, then soak it in 8% dilute nitric acid for 1 minute, rinse it with deionized water several times, and use it as the cathode after drying;

[0033] (3) With the graphite sheet eq...

Embodiment 3

[0039] A preparation method of aluminum-based graphene and carbon nanotube composite heat dissipation material, characterized in that it comprises the following steps:

[0040] (1) put into the same amount of graphene powder and carbon nanotube respectively in dehydrated ethanol solution, be made into the mixed solution that concentration is 0.1mg / ml graphene, carbon nanotube, then add aluminum salt solution, be made into The mixed solution of aluminum salt graphene and carbon nanotubes with an aluminum salt concentration of 4 mg / ml is dispersed by ultrasonic wave for 4 hours to obtain a mixed electrophoretic solution of uniformly dispersed aluminum salt graphene and carbon nanotubes;

[0041] (2) Ultrasonicate an aluminum sheet with a thickness of 0.1 mm in absolute ethanol solution for 10 minutes, then soak it in 6% dilute nitric acid for 1 minute, rinse it with deionized water several times, and use it as the cathode after drying;

[0042] (3) With the graphite sheet equiva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com