Preparation of three-dimensional macropore-mesopore lithium ion sieve

A three-dimensional macroporous, lithium ion technology, applied in the field of nanomaterials, can solve the problems of increased mass transfer resistance, decreased adsorption capacity, and decreased adsorption rate, and achieves the effects of increasing adsorption capacity, increasing adsorption rate, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

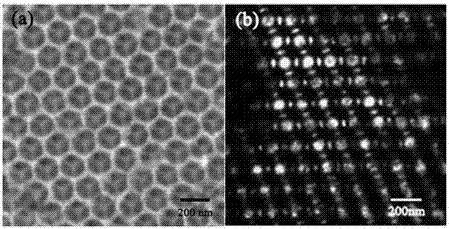

[0038] Preparation of Opal Polystyrene Hard Templates

[0039] Add 0.45 g of sodium dodecylbenzenesulfonate and 0.6 g of potassium persulfate into a three-necked round-bottomed flask filled with 150 ml of water and 270 ml of ethanol, and dissolve under magnetic stirring at room temperature. After the solid was dissolved, the temperature of the solution was raised to 71 °C under the protection of nitrogen, and then 36 ml of styrene was quickly injected into the three-necked flask with a needle (the styrene needs to be washed with 0.5 mol / L NaOH solution first to remove the polymerization inhibitor), Stir evenly to generate a vortex, and reflux at 71 °C for 19 h to obtain a milky white solution. The obtained solution was filtered with absorbent cotton to remove large agglomerates, and bottled for preservation. Add the prepared polystyrene emulsion into a beaker, the height of the solution is preferably 1-2 cm, and place the beaker in an oven at 70 °C until the solvent evaporate...

Embodiment 2

[0041] Three-dimensional macroporous-mesoporous lithium titanate 3DM-Li 4 Ti 5 o 12 Precursor preparation

[0042] Add 1.32 g of anhydrous lithium acetate, 0.55 g of P123, 17 mL of glacial acetic acid, and 37 mL of isopropanol into a round bottom flask, stir magnetically until the solids dissolve, then pipette 7.4 mL of isopropyl titanate In the round bottom flask, continue stirring for 10 min to obtain a light yellow homogeneous solution.

Embodiment 3

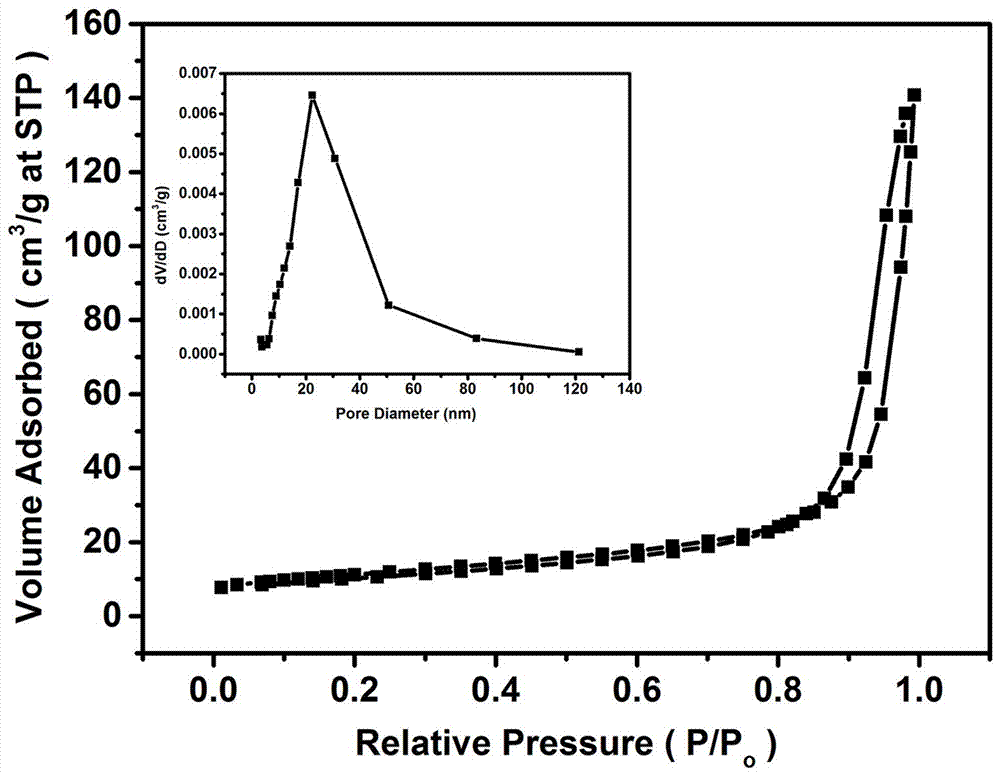

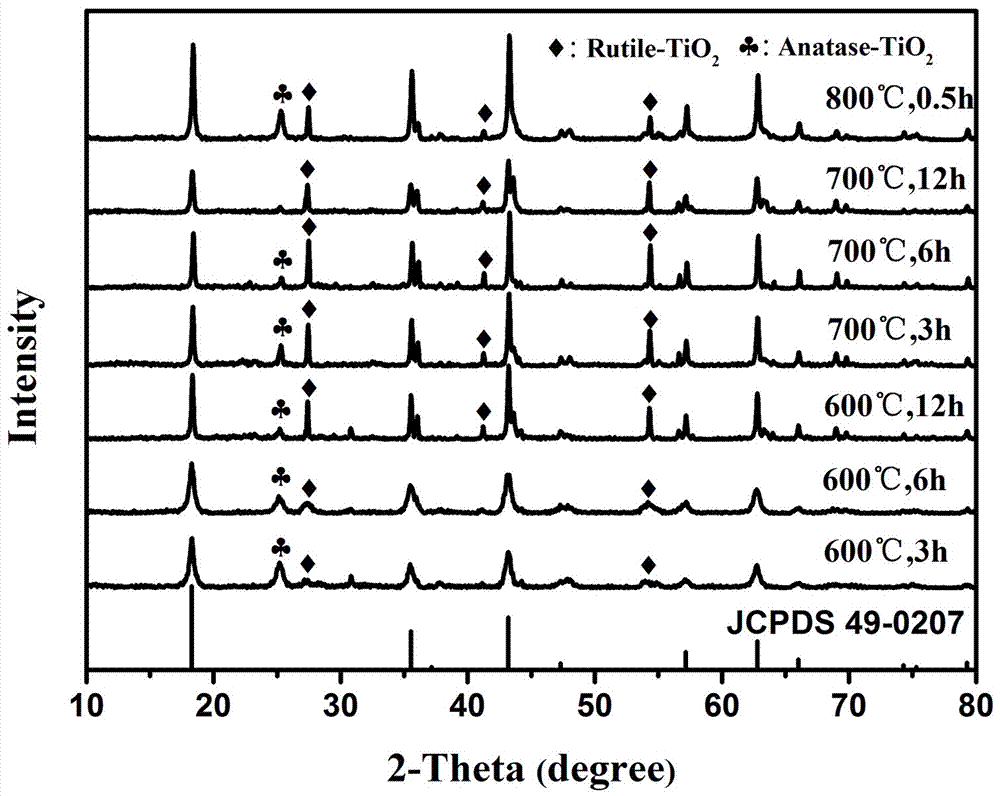

[0044] Three-dimensional macroporous-mesoporous lithium titanate 3DM-Li 4 Ti 5 o 12 preparation of

[0045] The prepared lithium titanate precursor solution was injected into the block polystyrene template, and after it was completely wetted, it was placed in an oven at 70 °C for 24 h at room temperature after the solvent evaporated. Using the step-by-step calcination method, the bulk product was first calcined in a muffle furnace at 200 °C for 2 h with a heating rate of 1 °C / min, and then the temperature was raised to 600 °C for 6 h with a heating rate of 1 °C / min .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com