Core-shell structure material and preparation method and applications thereof

A core-shell structure and composite material technology, applied in the field of electrochemistry, can solve the problems of electrolyte entry and polysulfide ion dissolution, harsh conditions, poor repeatability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Further, the preparation method includes: after uniformly mixing the mesoporous carbon material and elemental sulfur powder, heating at 100-200°C for 12-24 hours to form a carbon-sulfur composite material, and then mixing with polymer monomers and The initiator and / or polymer are thoroughly mixed in a solvent to produce the polymer-coated core.

[0038] Among them, typical polymers can be selected from polyacrylonitrile, polyvinyl chloride, polystyrene and other substances that can undergo dehydrogenation reaction with elemental sulfur. Correspondingly, typical initiators can be selected from radical initiators such as azobisisobutyronitrile (AIBN), potassium persulfate, and the like.

[0039] Another aspect of the embodiments of the present invention also provides the use of the aforementioned core-shell structure materials in the preparation of lithium-sulfur batteries.

[0040] Another aspect of the embodiments of the present invention also provides a lithium-sulfur...

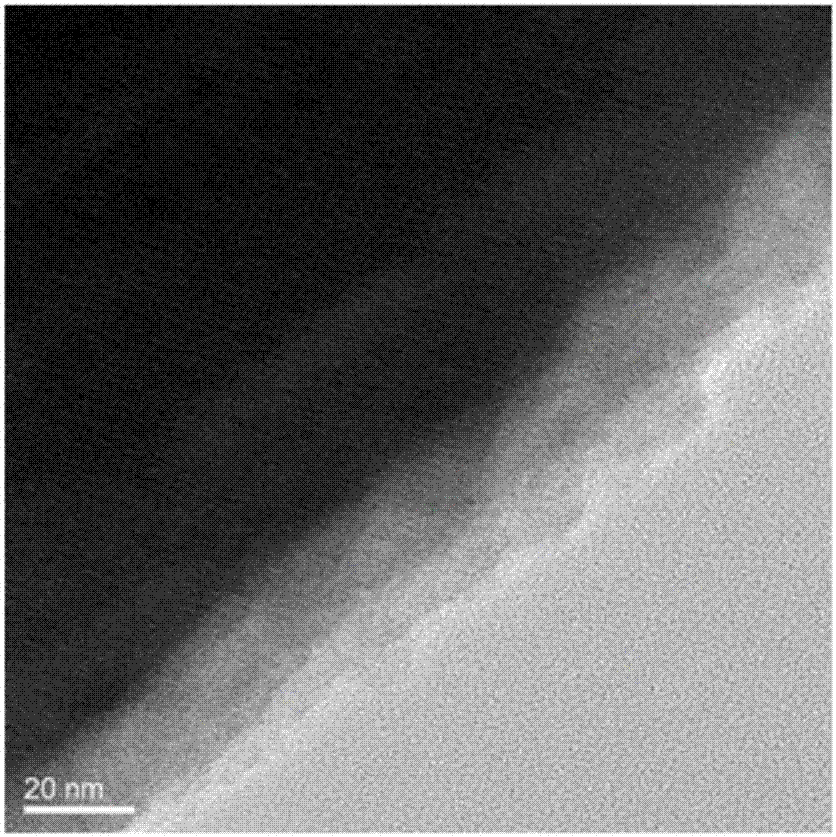

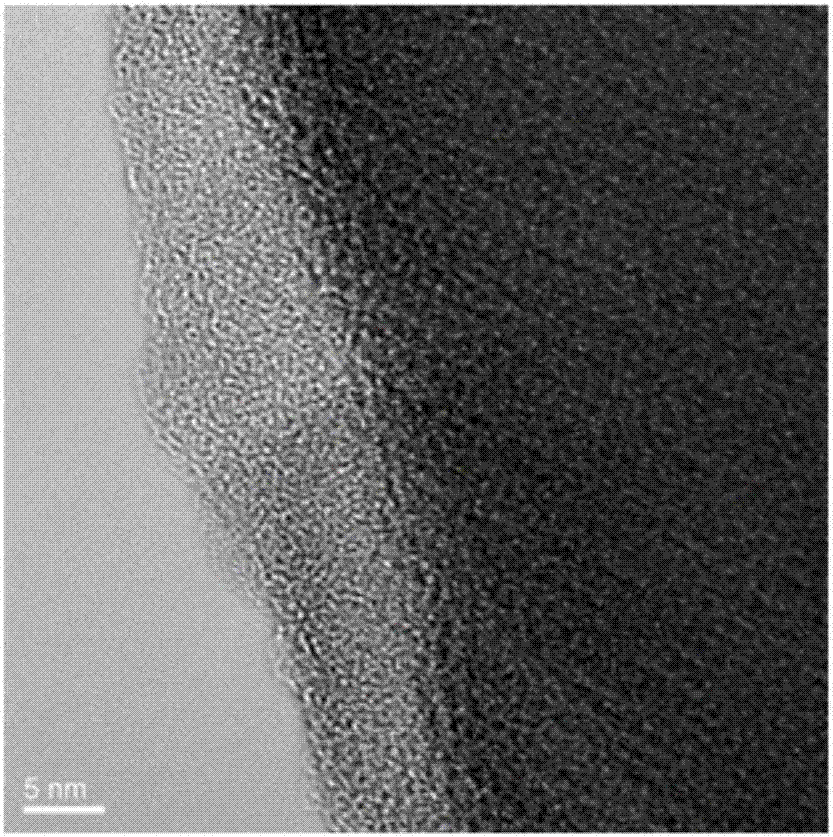

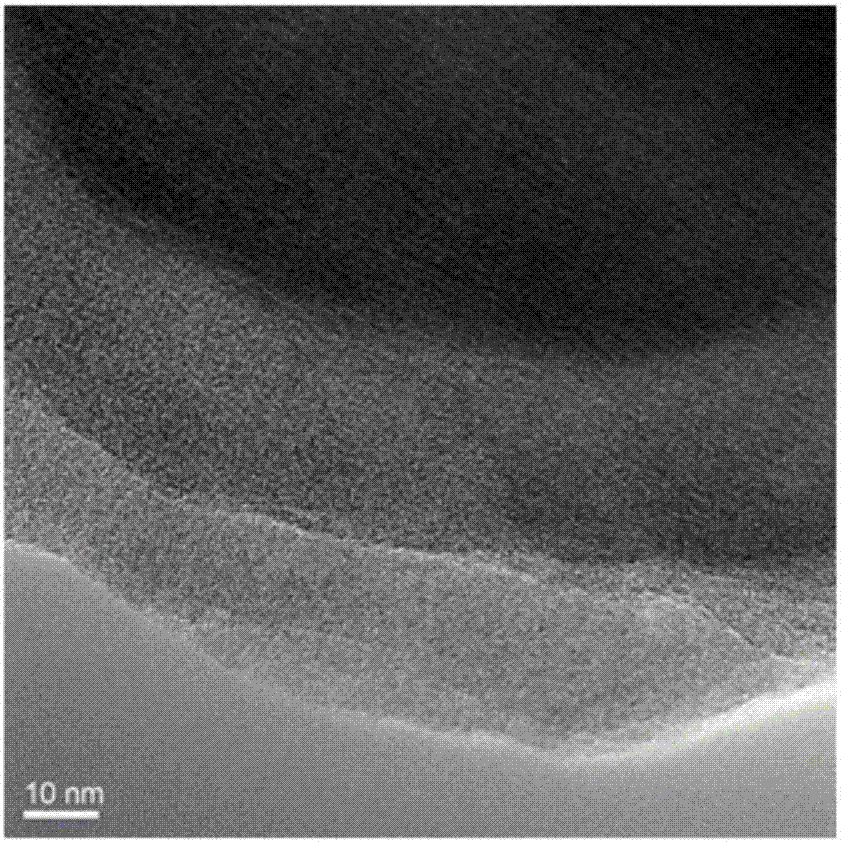

Embodiment 1

[0050] Mix 3 g of commercially available sulfur powder and 7 g of mesoporous carbon material (commercial mesoporous carbon material, its pore size distribution is 2-5 nm, and the pore volume is about 1.0 cm 3 / g) mix evenly, and heat at 100-200° C. for 12-24 hours to obtain a carbon-sulfur composite material. Then add 0.5g of carbon-sulfur composite material into 50ml of ethanol, and stir to disperse to obtain a mixed solution. Under strong stirring, 10ml of acrylonitrile monomer and 75mg of azobisisobutyronitrile (AIBN) were sequentially added to the aforementioned mixed solution, sealed, and polymerized at 65° C. for 3 hours under a nitrogen atmosphere. The obtained product is successively centrifuged, washed and dried to prepare polyacrylonitrile-coated carbon-sulfur material. Mix 100 mg of the prepared polyacrylonitrile-coated carbon-sulfur material with 300 mg of elemental sulfur, and calcinate at 300 ° C for 6 h under the protection of argon to form an organic sulfur-co...

Embodiment 2

[0056] Mix 3 g of commercially available sulfur powder and 7 g of mesoporous carbon material (commercial mesoporous carbon material, its pore size distribution is 2-5 nm, and the pore volume is about 1.0 cm 3 / g) mix evenly, and heat at 100-200° C. for 12-24 hours to obtain a carbon-sulfur composite material. Then, the above-mentioned carbon-sulfur composite material was added to the dimethyl sulfoxide solution containing polyacrylonitrile under the action of strong stirring, ultrasonicated for 1 hour, and then heated to volatilize the solvent dimethyl sulfoxide to obtain a polyacrylonitrile-coated carbon-sulfur materials. Mix 100 mg of the prepared polyacrylonitrile-coated carbon-sulfur material with 100 mg of elemental sulfur, and calcinate at 300 ° C for 6 h under the protection of argon to form an organic sulfur-coated carbon-sulfur composite material (that is, a material with a core-shell structure) ).

[0057] The organic sulfur-coated carbon-sulfur composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com