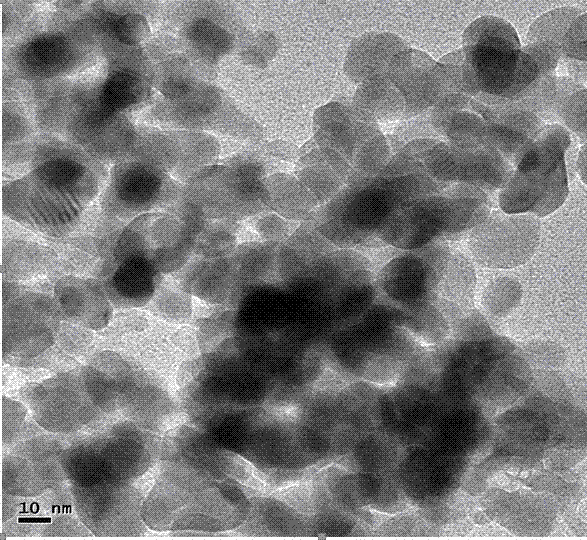

Ni-Zn-Co metal composite catalyst and preparation method thereof

A metal composite and catalyst technology, applied in the direction of carbon compound catalysts, metal/metal oxide/metal hydroxide catalysts, catalysts, etc., to achieve the effects of good dispersion, high acetylene conversion rate, and high ethylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] On the other hand, the present invention provides the preparation method of above-mentioned catalyst, comprises the following steps:

[0030] Step 1: Weigh nickel acetylacetonate, zinc acetylacetonate and cobalt acetylacetonate, add them into oleylamine, and stir until all acetylacetonate salts are dissolved to obtain a mixed solution;

[0031] Step 2: placing the mixed solution in a mixed atmosphere of hydrogen and acetylene, stirring, reacting at a certain temperature, cooling, and centrifuging to obtain a calcined precursor;

[0032] Step 3: calcining the calcined precursor obtained in step 2 in an air atmosphere to obtain a composite oxide;

[0033] Step 4: reducing the composite oxide with hydrogen to obtain the Ni-Zn-Co metal composite catalyst.

[0034] The specific steps are:

[0035] Step 1: Weigh a certain mass of nickel acetylacetonate, zinc acetylacetonate and cobalt acetylacetonate in proportion, add them into a dynamic reaction kettle equipped with oleyl...

Embodiment 1

[0050] The preparation method of catalyst comprises the following steps:

[0051] Step 1: Add 100g of oleylamine solvent into the dynamic reaction kettle, then add 1g of nickel acetylacetonate, 3g of zinc acetylacetonate and 0.5g of cobalt acetylacetonate into the solution in sequence, and keep stirring until the acetylacetonate is completely dissolved in oleylamine That's it.

[0052] Step 2: After sealing the dynamic kettle, feed the mixed gas of hydrogen and acetylene, and the volume ratio of hydrogen and acetylene is 4:1, inflate and exhaust at least 5 times, then close the outlet of the dynamic kettle; Mixed gas of hydrogen and acetylene, pressurized to 0.01MPa, close the mixed gas. Adjust the rotational speed of the dynamic reaction kettle to 500r / min, and the temperature to 100°C, and naturally cool to room temperature after reacting for 10 hours.

[0053] Step 3: After exhausting the dynamic reactor, stop stirring. Centrifuge the mixture in the kettle, and alternate...

Embodiment 2- Embodiment 8

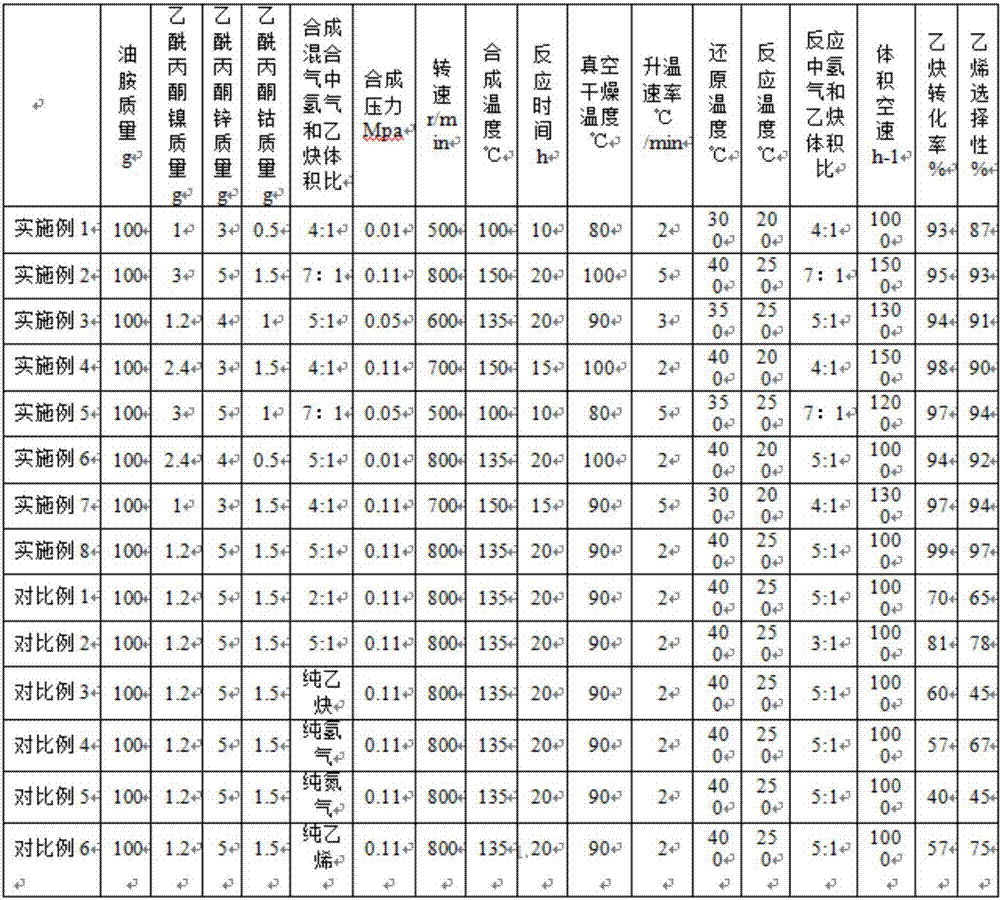

[0057] The present invention has passed multiple sets of experimental verifications in the laboratory. The catalyst preparation process in the verification process and the steps of preparing ethylene by hydrogenation of acetylene are all the same as the method steps introduced in Example 1. The difference lies in the proportioning of the catalyst components. And the control parameters of the preparation process and the acetylene hydrogenation reaction conditions are different, and the specific differences are shown in the table below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com