B and N co-doped three-dimensional graphene block and preparation method and application thereof

A graphene and co-doping technology, applied in the field of material science, can solve the problems of difficult stable existence of doping atoms and difficult boron doping, and achieve the effects of excellent lithium-sulfur battery performance, high specific surface area, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

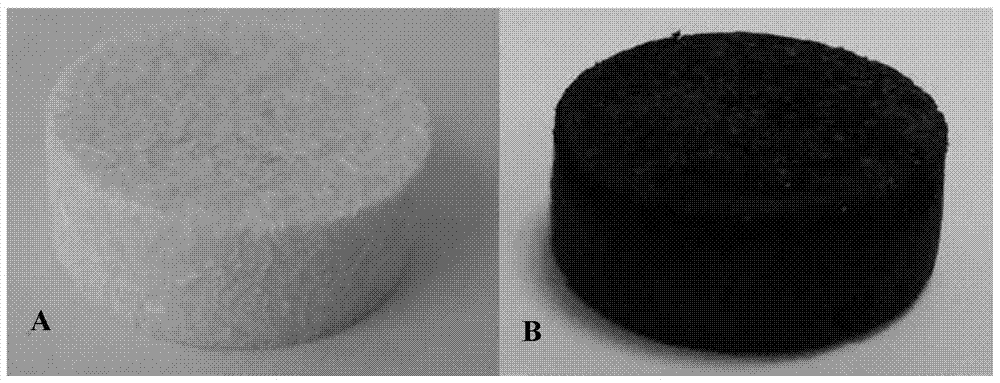

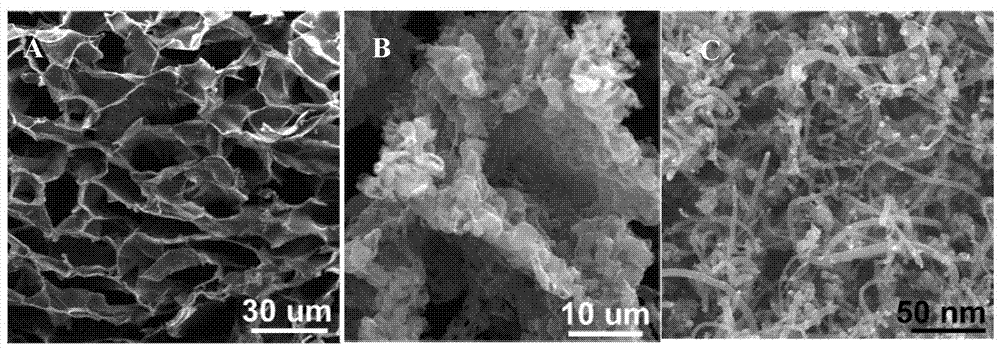

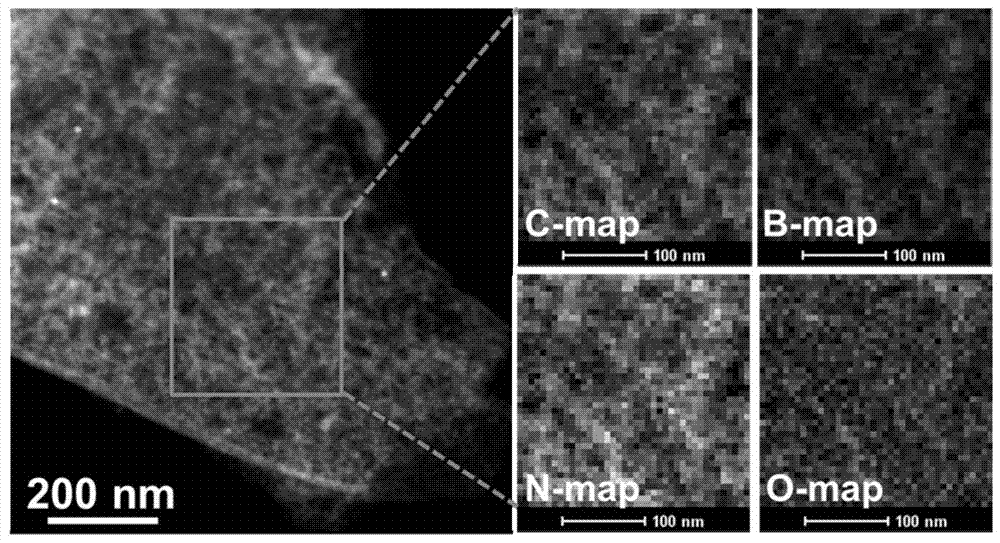

Embodiment 1

[0053] (1) A certain amount of agar (2g), boron oxide (1g), nickel chloride (1g) and urea (1g) were mixed and heated to 85°C, stirred and dissolved in 50mL aqueous solution, cooled and formed to obtain a uniform three-dimensional gel ( The freeze-drying temperature is minus 78°C and the time is 24 hours); it should be noted that the concentration of the precursor is the key factor for the formation of the three-dimensional structure. Too high or too low concentration is not conducive to the formation of three-dimensional structure, and an appropriate concentration is required;

[0054] (2) Freeze-dry the obtained three-dimensional gel (the freeze-drying temperature is minus 78°C for 24 hours), and the vacuum degree is less than 2Pa;

[0055] (3) The obtained three-dimensional block is used as a carbon source (5 sccm) by chemical vapor deposition method, and 10°C / min is heated to 700°C to directly grow graphene for 60 minutes (whether the protective gas is also included in the ...

Embodiment 2

[0059] (1) A certain amount of agar (2g), boron oxide (1g), nickel acetylacetonate (1g) and dicyandiamide (1g) were mixed and heated to 85°C, stirred and dissolved in 50mL aqueous solution, cooled and formed to obtain a uniform three-dimensional gel Glue (freeze-dried at minus 78°C for 24 hours); it should be noted that the concentration of the precursor is the key factor for the formation of the three-dimensional structure. Too high or too low a concentration is not conducive to the formation of a three-dimensional structure, and an appropriate concentration is required;

[0060] (2) Freeze-dry the obtained three-dimensional gel (the freeze-drying temperature is minus 78°C for 24 hours), and the vacuum degree is less than 2Pa;

[0061] (3) The obtained three-dimensional block is passed through a chemical vapor deposition method, ethylene is used as a carbon source (5 sccm), and the temperature is raised to 800 ° C at 10 ° C / min to directly grow graphene for 60 minutes (whet...

Embodiment 3

[0065] (1) A certain amount of agar (1g), gelatin (1g), boron oxide (1g), nickel chloride (1g) and urea (1g) was mixed and heated to 85°C, stirred and dissolved in 50mL aqueous solution, and cooled to form a uniform 3D gel; it should be noted that the concentration of the precursor is the key factor for the formation of the 3D structure. Too high or too low concentration is not conducive to the formation of three-dimensional structure, and an appropriate concentration is required;

[0066] (2) Freeze-dry the obtained three-dimensional gel (the freeze-drying temperature is minus 78°C for 24 hours), and the vacuum degree is less than 2Pa;

[0067] (3) The obtained three-dimensional block is passed through a chemical vapor deposition method, ethylene is used as a carbon source (5 sccm), and the temperature is raised to 800 ° C at 10 ° C / min to directly grow graphene for 60 minutes (whether a protective gas is also included in the chemical vapor deposition process, For example,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com