Novel inorganic-organic composite type high-molecular coagulant

A polymer coagulant and composite technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water treatment parameter control, water/sewage treatment, etc., can solve the problem that the preparation process is not perfect and affects the stability of the composite coagulant And use performance, refractory degradation and environmental protection, etc., to achieve the effect of high charge density, increased adsorption and bridging ability, and large pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

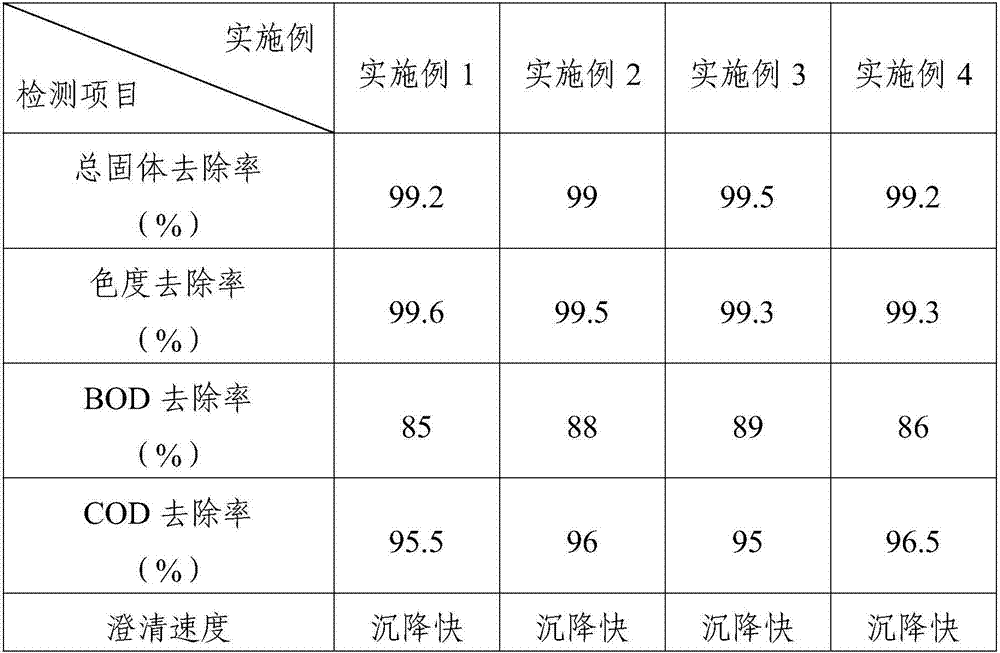

Examples

Embodiment 1

[0018] A novel inorganic-organic composite polymer coagulant, comprising the following raw materials in parts by weight: 5 parts of modified polyacrylamide, 5 parts of dimethyl diallyl ammonium chloride, 13 parts of magnesium chloride, polymerized chloride 65 parts of aluminum, 1 part of calcium chloride, 8 parts of bentonite, 0.3 parts of sodium bicarbonate.

[0019] The preparation method of modified polyacrylamide is as follows: mix polyacrylamide and formaldehyde in a constant temperature water bath at 50°C and stir for 10 minutes, then add dimethylamine dropwise and heat for 4 hours, cool to 15°C, and adjust the pH value with hydrochloric acid To 5, finally add dimethyl sulfate slowly, react for 1h, pour the obtained product into cold water at 5°C, filter with suction, wash, and dry under negative pressure at 40°C to obtain modified polyacrylamide.

[0020] The raw materials of the polyaluminum chloride include hydrochloric acid and a mixture formed by mixing aluminum chi...

Embodiment 2

[0022] A novel inorganic-organic composite polymer coagulant, comprising the following raw materials in parts by weight: 1 part of modified polyacrylamide, 5 parts of dimethyl diallyl ammonium chloride, 15 parts of magnesium chloride, polymerized chloride 60 parts of aluminum, 1.5 parts of calcium chloride, 5 parts of bentonite, and 0.5 parts of sodium bicarbonate.

[0023] The preparation method of modified polyacrylamide is as follows: mix polyacrylamide and formaldehyde in a constant temperature water bath at 60°C and stir for 30 minutes, then add dimethylamine dropwise and heat for 6 hours, cool to 15°C, and adjust the pH value with hydrochloric acid To 5, finally add dimethyl sulfate slowly, react for 1.5h, pour the obtained product into cold water at 5°C, filter with suction, wash, and dry under negative pressure at 45°C to obtain modified polyacrylamide.

[0024] The raw materials of the polyaluminium chloride include hydrochloric acid and a mixture formed by mixing alu...

Embodiment 3

[0026] A novel inorganic-organic composite polymer coagulant, comprising the following raw materials in parts by weight: 10 parts of modified polyacrylamide, 1 part of dimethyl diallyl ammonium chloride, 10 parts of magnesium chloride, polymerized chloride 70 parts of aluminum, 1 part of calcium chloride, 10 parts of bentonite, 0.2 parts of sodium bicarbonate, and 2 parts of calcium hydroxide.

[0027] The preparation method of modified polyacrylamide is as follows: mix polyacrylamide and formaldehyde in a constant temperature water bath at 70°C and stir for 15 minutes, then add dimethylamine dropwise and heat for 5 hours, cool to 15°C, and adjust the pH value with hydrochloric acid To 5, finally add dimethyl sulfate slowly, react for 2 hours, pour the obtained product into cold water at 5°C, filter with suction, wash, and dry under negative pressure at 60°C to obtain modified polyacrylamide.

[0028] The raw materials of the polyaluminium chloride include hydrochloric acid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com